2 tightening torques, 3 pressure/temperature diagram, Tightening torques – Richter GS Series Strainers User Manual

Page 4: Pressure/temperature diagram, Series gs

Series GS

Page 4

9540-060-en

Revision 05

TM 6506

Edition 05/2006

1.2 Tightening torques

All screws greased, tighten in diametrically

opposite sequence!

The tightening torques for pipe screws and body

screws mentioned must not be exceeded. For an

exception, see Section 8, Flange connection valve /

pipe is leaking.

The following tightening torques are recommended.

Pipe screws, flanges to ISO/DIN

Flange nom.

size

Screws

Tightening

torque

[mm] [inch]

[ISO/DIN]

[Nm]

15

½“

4 x M12

6

20

¾“

4 x M12

8

25

1

4 x M12

10

40

1½

4 x M16

20

50

2

4 x M16

26

65

--

4 x M16

40

80

3

8 x M16

25

100

4

8 x M16

35

Pipe screws, flanges to ASME Class 150 or flanges

ISO/DIN drilled to ASME Class 150

Flange nom.

size

Screws

Tightening torque

[mm] [inch]

[ASME]

[in-lbs]

[Nm]

15

½“

4 x ½“

45

5

20

¾“

4 x ½“

55

6

25

1“

4 x ½“

70

8

40

1½“

4 x ½“

135

15

50

2“

4 x

N

“

220

25

65

2½“

4 x

N

“

265

30

80

3“

4 x

N

“

400

45

100

4“

8 x

N

“

310

35

Cover screws

Flange nom.

size

Screws

Tightening torque

[mm]

[inch]

[ISO/DIN]

[Nm]

[in-lbs]

15

½“

4 x M10

30

266

20

¾“

4 x M10

30

266

25

1

4 x M12

50

442

40

1½

4 x M12

50

442

50

2

4 x M12

50

442

65

--

4 x M12

50

442

80

3

8 x M12

50

442

100

4

8 x M12

50

442

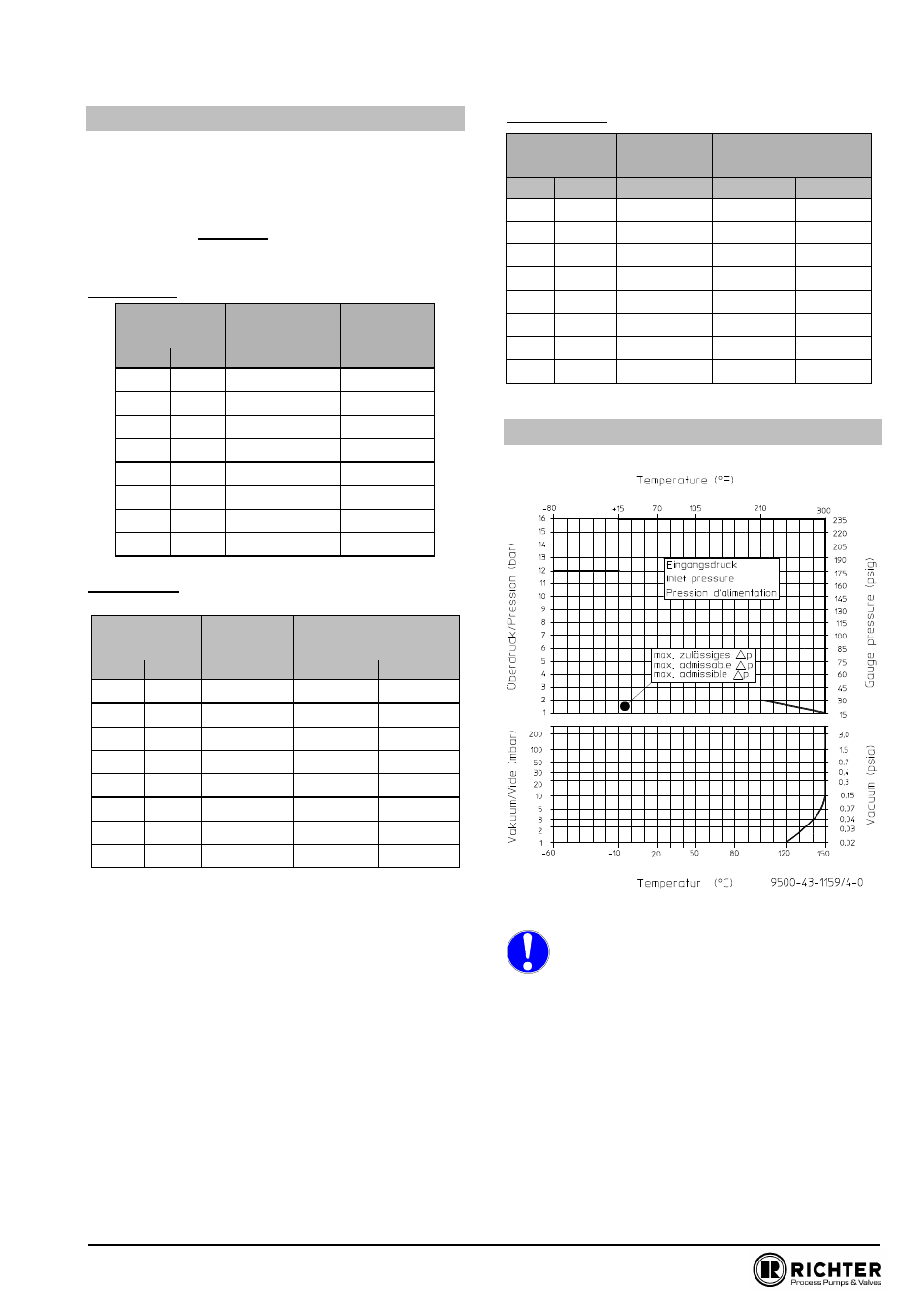

1.3 Pressure/temperature diagram

When used in the minus temperature range,

the regulations applicable in the country in

question must be observed.