3 end position adjustments, 4 end position adjustments for standard actuators, 1 double-acting actuators – Richter RA Series Actuators User Manual

Page 7: 2 single-acting actuators, 5 removal and installation of components, 3 end, Position, Adjustments, End position adjustments for standard actuators7, 1 double-acting

Installation and Operating Manual

Series RA

9590-050-de

Revision 01

TM 5515 MPE/Wm

Seite 7

Edition 07/2003

4.3 End position adjustments

Never set the adjusting screws against the

action of pressure.

Ensure that the actuator moves in the correct

rotational direction.

When using overdrive-unprotected valves, make sure

that the maximum pivoting angle is set so that the

valve seat sealing surfaces are not overdriven.

4.4 End position adjustments for

standard actuators

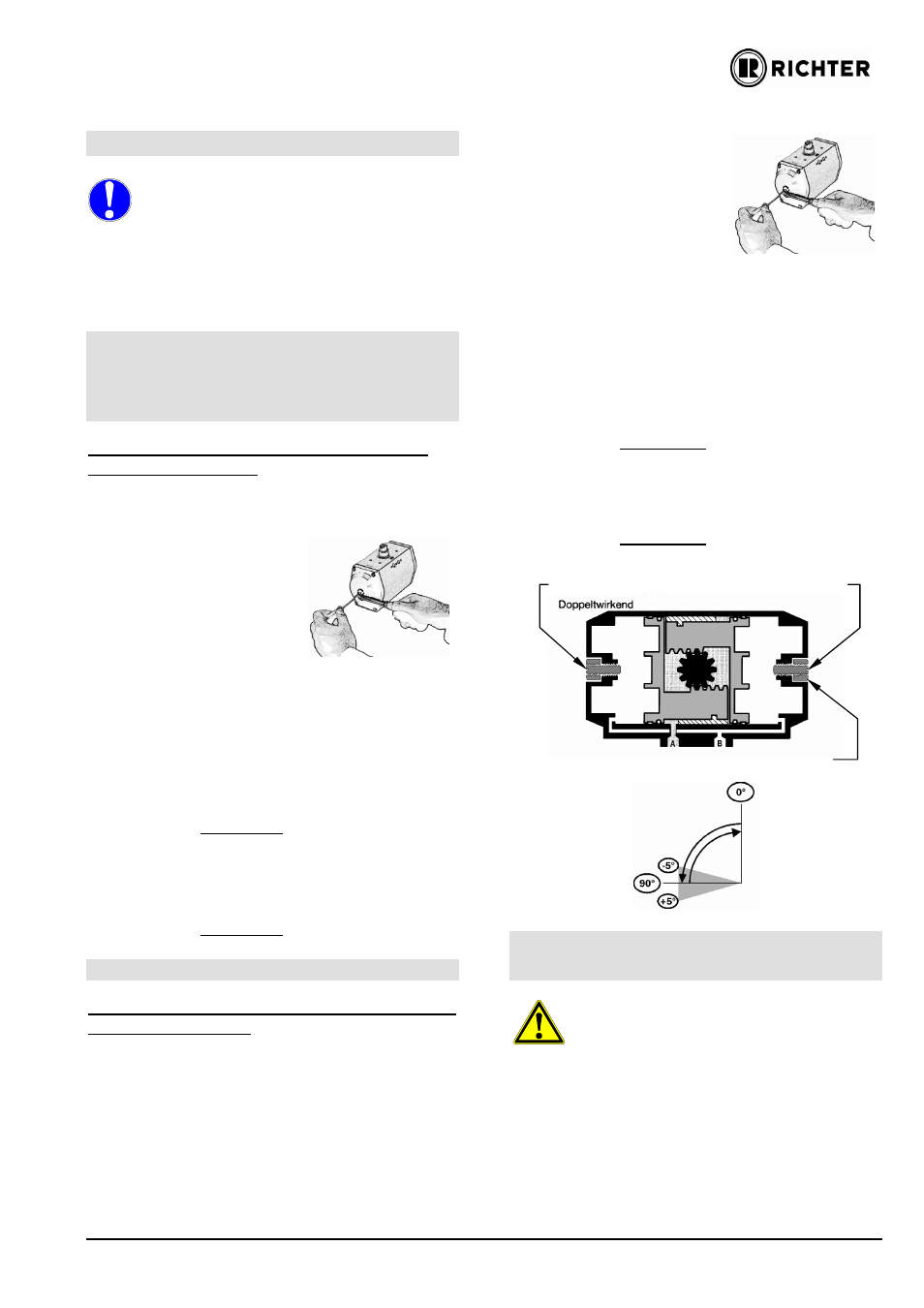

4.4.1 Double-acting actuators

Adjusting the outer stroke limiting screw for a

double-acting actuator

1. Move the piston to the switching position via ap-

plication of pressure at canal A.

2. Loosen the locking nuts

D1 and D2 at the end po-

sition adjustment screws.

3. Remove air pressure from

the actuator.

4. Turn the adjustment screw

D2 anti-clockwise ca. 5 times

5. Turn the adjustment screw D1 in one or the other

direction to reach the desired setting point for the

end position of the valve.

6. Apply air to canal A and check the adjusted posi-

tion. If required, repeat steps 3 and 5.

7. Tighten the locking nut on adjusting screw D1 with

the defined torque.

Torques see Section 1.2.

8. Turn the adjustment screw D2 clockwise against

the piston.

9. Tighten the locking nut on adjusting screw D2 with

the defined torque.

Torques see Section 1.2.

4.4.2 Single-acting actuators

Adjusting the outer stroke limiting screw for a

single-acting actuator

1. Move the piston to the switching position via ap-

plication of pressure at canal A.

2. Loosen the locking nuts

D1 and D2 at the end posi-

tion adjustment screws.

3. Remove air pressure from

the actuator.

4. Turn the adjustment screw

D2 anti-clockwise ca. 5

times

5. Turn the adjustment screw D1 in one or the other

direction to reach the desired setting point for the

end position of the valve.

6. Apply air to canal A and check the adjusted end

position. If necessary repeate proceeding (Point 3

and 5).

7. Tighten the locking nut on adjusting screw D1 with

the defined torque.

Torques

see Section 1.2.

8. Turn the adjustment screw D2 clockwise against

the piston.

9. Tighten the locking nut on adjusting screw D2 with

the defined torque.

Torques

see Section 1.2

4.5 Removal and installation of

components

Warning - Danger of injury!

Never drive the piston out of the casing with com-

pressed air.

Before working on the actuator, isolate it from the

compressed air supply.

For single-acting actuators, remove the returning

springs.

The circlip must not be over-stretched when disman-

tling.

Parts and dimensions: see drawing 9590-00-0001.

Adjusting screw D2

Locking nut

Adjusting screw D1

Canal A Canal B

Double-acting