Shr series woodburning fireplaces, Installing line for gas logs – Vermont Casting SHR36 User Manual

Page 19

19

SHR Series Woodburning Fireplaces

20001384

removed from gas line tube to repack space around the

pipe. Material should be inserted from outside of the

fireplace and packed tightly to totally seal between the

pipe and tube.

Note: Gas pipe should not come in contact with any

wood structures until it has reached a point at least

one (1) inch away from fireplace side.

NOTE: When installing an ANSI Z21.11.2 ventless appli-

ance, the finishing material used for the mantel must be

rated at 250°F or greater.

BTU input of a gas appliance installed in fireplace should

be rated less than 100,000 BTU/Hr.

Gas pipe installation is intended for connection to a deco-

rative gas appliance only when (1.) incorporating an auto-

matic shutoff device and (2.) complying with the Standard

for Decorative Gas Appliances for Installation in Vented

Fireplaces (ANSI Z21.60) or CSA draft requirements

for Gas-Fired Log Lighters for Woodburning Fireplaces

(Draft No. 4, August 1993).

Decorative gas appliance should be installed in accor-

dance with the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 (latest edition).

CAUTION: WHEN USING DECORATIVE GAS

APPLIANCE, FLUE DAMPER MUST BE SET

IN FULLY OPEN POSITION. IF YOU HAVE

GLASS DOORS ON THE FIREPLACE, THEY

MUST ALSO BE FULLY OPENED.

WARNING: DO NOT OPERATE AN

UNVENTED GAS LOG SET IN THIS FIRE-

PLACE WITH THE CHIMNEY REMOVED.

WARNING: WHEN INSTALLING AN

UNVENTED GAS LOG SET, THE CFM

CORPORATION MODEL AH3244BK OR

AH3244PB 4" ADJUSTABLE HOOD MUST BE

USED.

Installing Line for Gas Logs

CFM Corporation fireplaces are designed to accept a 1/2

inch gas line for installation of an approved gas appli-

ance. (CFM Corporation manufactures a wide variety of

gas logs for use in CFM Corporation fireplaces.)

Be sure to have the appliance installed in accordance

with building codes.

Gas connection may enter from either left or right side of

the fireplace.

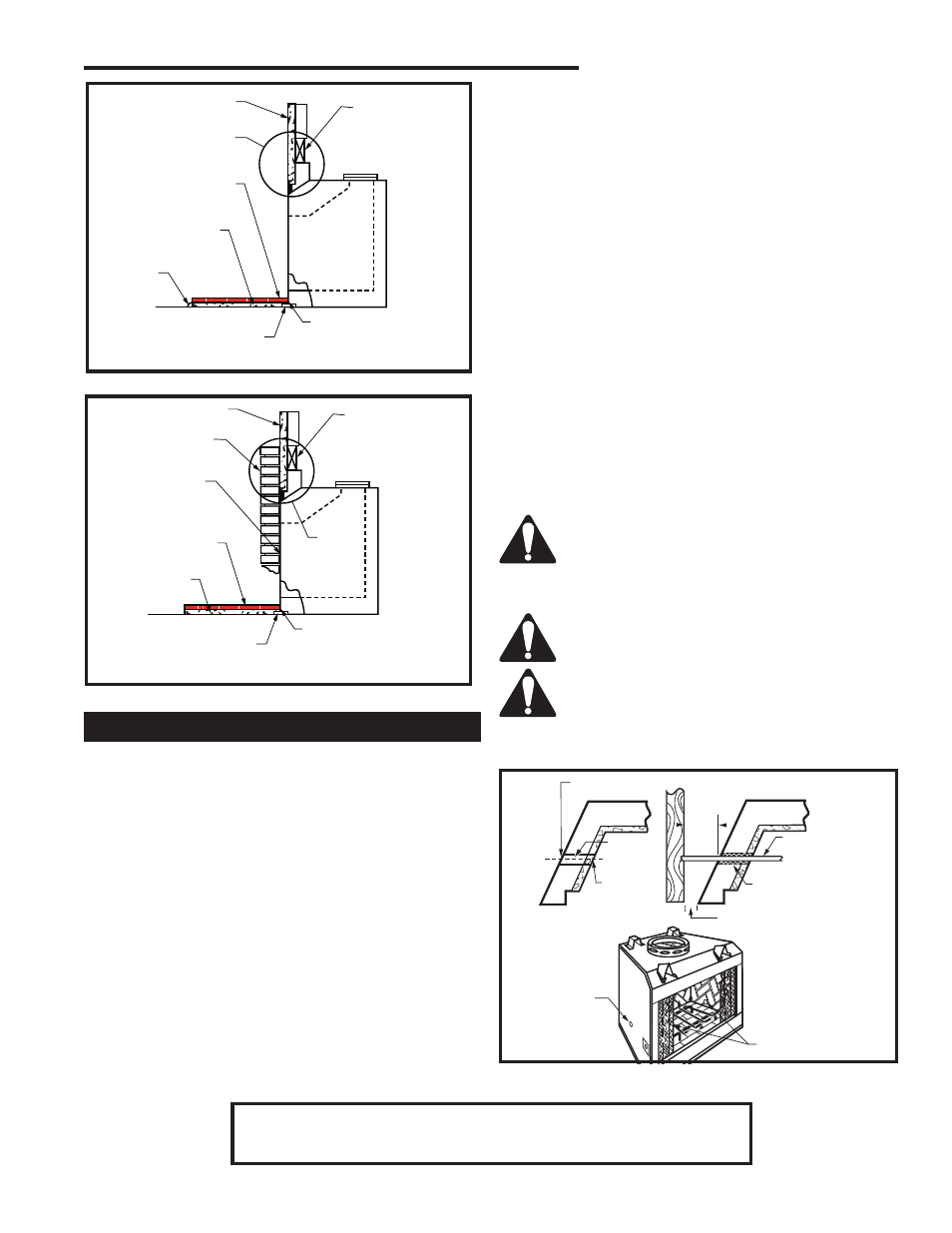

Locate appropriate gas line in the outer casing of fire-

place and remove insulation from gas line tube. (Fig. 35)

From inside the fireplace, locate the knockout on the fire-

brick -- be sure you are on the appropriate or "gas line"

side of the fireplace. Using a flat bladed screwdriver or

small chisel and hammer, carefully tap around the knock-

out until it loosens and falls out.

Install 1/2 inch certified gas pipe through opening. After

gas pipe installation is complete, use insulation that was

FP1171

sealing detail

12/20/01 djt

Wall Covering

2 x 4 Header

- Do Not Notch at

Ledge Brackets

Fig. 22 or 23

Hearth Extension

Hearth

Extension Insulation

Molding used to

Fasten Hearth

Extension

in Place

Majestic Safety Strips Must

be Overlapped 1/2" Min.

Seal Crack Between

Fireplace and Hearth

Extension with

Noncombustible Material

FP1171

Fig. 33 Sealing detail.

FP1172

sealing detail 2

12/20/01 djt

2 x 4 Header

- Do Not Notch at

Ledge Brackets

Fig. 24

Wall Covering

Noncombustible

Decorative Facing

Seal All Cracks

Between Fireplace

Surround and Wall

Materials with

Noncombustible

Material

Noncombustible

Decorative Covering

Majestic Safety Strips Must

be Overlapped 1/2" Min.

Seal Crack Between Fire-

place and Hearth Exten-

sion with Noncombustible

Material

FP1172

Fig. 34 Sealing detail.

Hearth

Extension

1"

Min.

FP560SHR

SHR series

5/12/99 djt

1/2"

FP560SHR

Fig. 35 Gas line access.

Hole in Outer Casing

Gas Line

Tubing

Ceramic

Knockout

Hole in

Outer Casing

Supply Line

Repack Insulation

Ceramic Knockout

(both sides)

Only unvented gas log sets which have been found to comply with

the Standard for Unvented Room Heaters, ANSI Z21.11.2, are to be

installed in this fireplace.

If installing an unvented gas log set, refer to statement below: