Bush Hog 300 User Manual

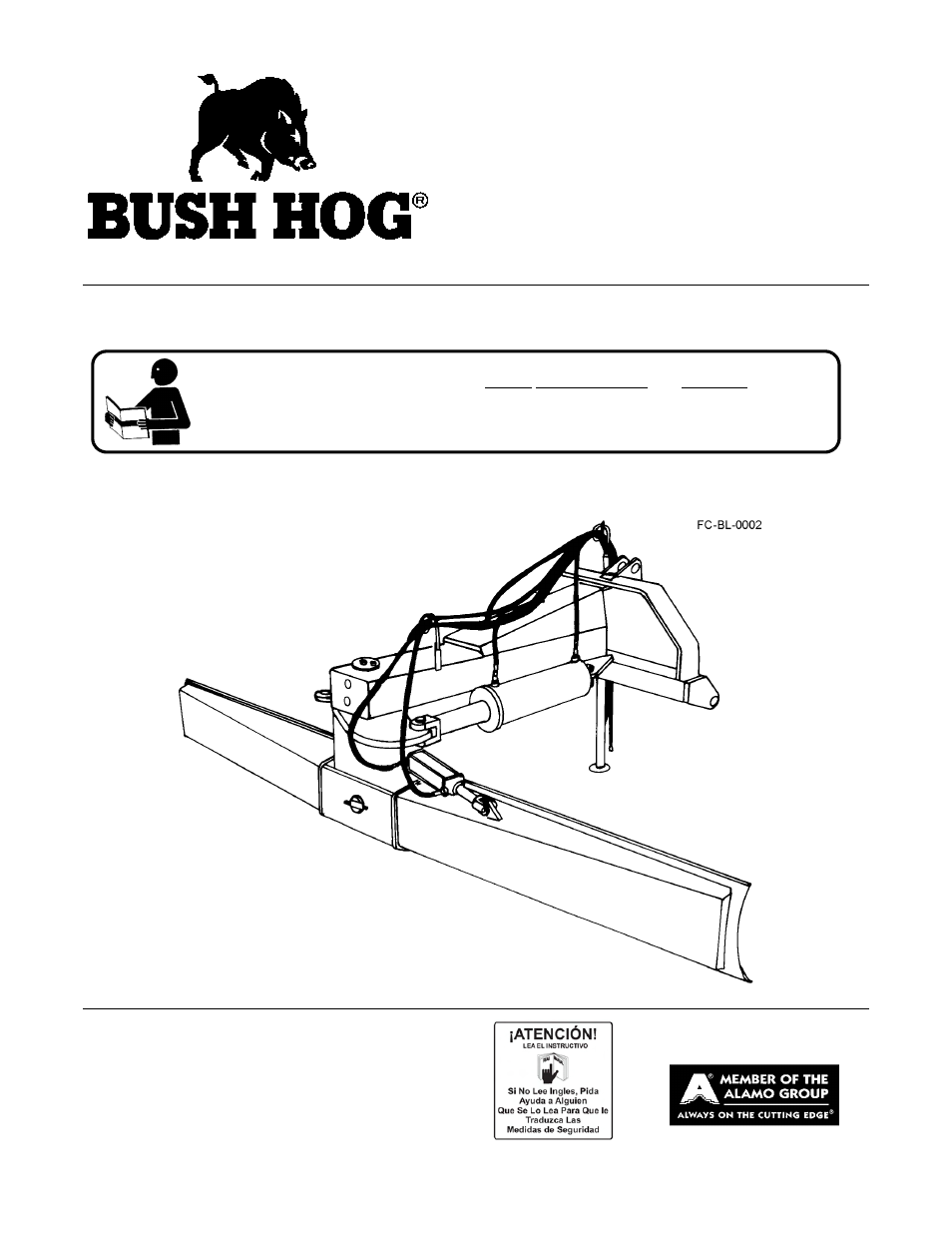

300 series, Operator’s manual, Rear mounted blade

Table of contents

Document Outline

- 300 Series

- OPERATOR’S MANUAL

- To the Owner/Operator/Dealer

- TABLE OF CONTENTS

- Safety Messages

- Decal Location

- 1. 00725746 1 PELIGRO Translate Safety Material

- 2. 02965262 1 WARNING Oil Penetration

- 3. 00786980 1 IMPORTANT Genuine Bush Hog Parts

- 4. 999000 1 WARNING Multi-Hazard for Blades

- 5. 999200 1 WARNING Multi-Hazard General

- 6. 03200347 * REFLECT SMV Emblem

- 7. 000678 2 INSTRUCT Grease Fitting Inside

- 8. 00763977 1 INSTRUCT Notice to Owner

- 9. 00786979 3 LOGO Bush Hog

- 10. 00786984 1 NAME 300-12

- 11. nfs 1 SER PLT Serial Plate

- 12. 1458393 2 REFLECT Amber Reflectors

- 13. 1458392 4 REFLECT Red Reflectors

- 14. 1458398 4 REFLECT Fluorescent

- 15. 49722 1 _________ Canister, Operator’s Manual

- 16. 00786978C 1 MANUAL Operator’s Manual

- SAFETY SECTION

- Decal Description

- Federal Laws and Regulations

- Assembly of Moldboard to Mainframe

- Gauge Wheel (Extra Equipment)

- Hydraulic System

- Selector Valve (Accessory Equipment)

- 1. Standard Equipment and Specifications

- 3. TRACTOR REQUIREMENTS

- 3.1 ROPS and Seat Belt

- 3.2 Tractor Horsepower

- 3.3 Tractor 3-Point Hitch

- 3.4 Front End Weight

- 4. GETTING ON AND OFF THE TRACTOR

- 5. STARTING THE TRACTOR

- 6. CONNECTING THE REAR BLADE TO THE TRACTOR

- 6.1 Connecting the Rear Blade

- 1. Shorten or remove the tractor drawbar to avoid interference when raising and lowering the rear blade.

- 2. Board the tractor and start the engine. Position the tractor to the blade with the 3- point lift arms positioned between the respective set of blade A-frame lift lugs. Note: Set the 3-point lift control to “Position Control” so that the lift a...

- 3. Turn off the tractor engine, set the parking brake, place the tractor in park, and dismount.

- 4. One lift arm at a time, align arm end hole between the set of holes of A-frame lift lugs. Insert hitch pin through the lug and arm holes and insert retaining pin into hitch pin. Walk around to opposite side and repeat procedure for remaining lift ...

- 5. Extend or retract the 3-point top link to align its end hole with the holes of the blade’s top link. Insert the top link pin and retain with the lynch pin.

- 6. Adjust any lower link check chains, guide blocks, or sway blocks to prevent the blade from swaying side to side and possible contact with tractor rear tires.

- 6.1 Connecting the Rear Blade

- 7. PRE-OPERATION INSPECTION AND SERVICE

- 8. DRIVING THE TRACTOR AND IMPLEMENT

- 9. OPERATING THE TRACTOR AND IMPLEMENT

- 10. Operating the Blade

- 14. TROUBLESHOOTING GUIDE

- Shearing M/B Carrier Lack of lubrication Lubricate Pivot Pin

- Pivot Pin Bolt Bolt not tightened properly Tighten Bolt to proper torque

- Bent Moldboard Small curve is normal from weld pull Can be removed but will not

- affect operation

- Hitting hidden objects Know soil conditions, keep

- speed to a minimum.

- Blade will not penetrate soil Cutting edge dull Replace Cutting edge

- Blade set to straight Increase Top Link length

- Soil too hard Use scarifiers to loosen soil

- A-Frame bent Hitting hidden objects in the backfill Use slow speed when in unknown

- position soil conditions

- Moldboard digging in too Blade pitch excessive Adjust Top Link

- much Soft ground. Install Gauge Wheel.

- Install Skid Shoes.

- Unable to hold level ground Tractor and Blade following contour Install Gauge Wheel

- Tractor Draft Control lifting Blade Set Tractor Draft Control

- Hydraulic Cylinder(s) Not enough pressure Check pressure

- will not operate Valve not connected properly Re-plumb Valve

- Quick Coupler not completely Complete connection

- connected

- Hydraulic Pump not shutting Using Open Center Valve Replace Valve or Conversion Plug

- off on Closed Center System and Main Relief

- Open Center Conversion Plug Replace with Closed Center Plug

- Pumping over Relief Valve Replace with No Relief Plug

- Oil leaking at hose Connection not tight Tighten connection

- connection Did not use sealant Apply a good sealant to connection

- Connection cracked from Replace cracked connection

- over-tightening

- Mismatched Connection threads Use correct connectors

- or types.

- OPERATION SECTION

- MAINTENANCE SECTION

- Lubrication

- Proper Torque For Fasteners

- Back Cover.pdf

- 300 Series

- Rear Mounted Blade

- LIMITED WARRANTY

- DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

- THIS LIMITED WARRANTY SHALL NOT APPLY:

- 1. To vendor items which carry their own warranties, such as engines, tires, and tubes.

- 2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

- 3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgement of Bush Hog such use affects its performance, stability or reliability.

- 4. If the unit has been altered or repaired outside of an authorized Bush Hog dealership in a manner which, in the sole judgement of Bush Hog, affects its performance, stability or reliability.

- 5. To normal maintenance service and normal replacement items such as gearbox lubricant, hydraulic fluid, worn blades, or to normal deterioration of such things as belts and exterior finish due to use or exposure.

- 6. To expendable or wear items such as teeth, chains, sprockets, belts, springs and any other items that in the company’s sole judgement is a wear item.

- TO THE OWNER/OPERATOR/DEALER