Switch locations key switch, Upper limit switch, Interlock switch – Broan 1059-C User Manual

Page 6: Trunnion nut, Removing plastic bags from trunnion nut, Drive screw

6

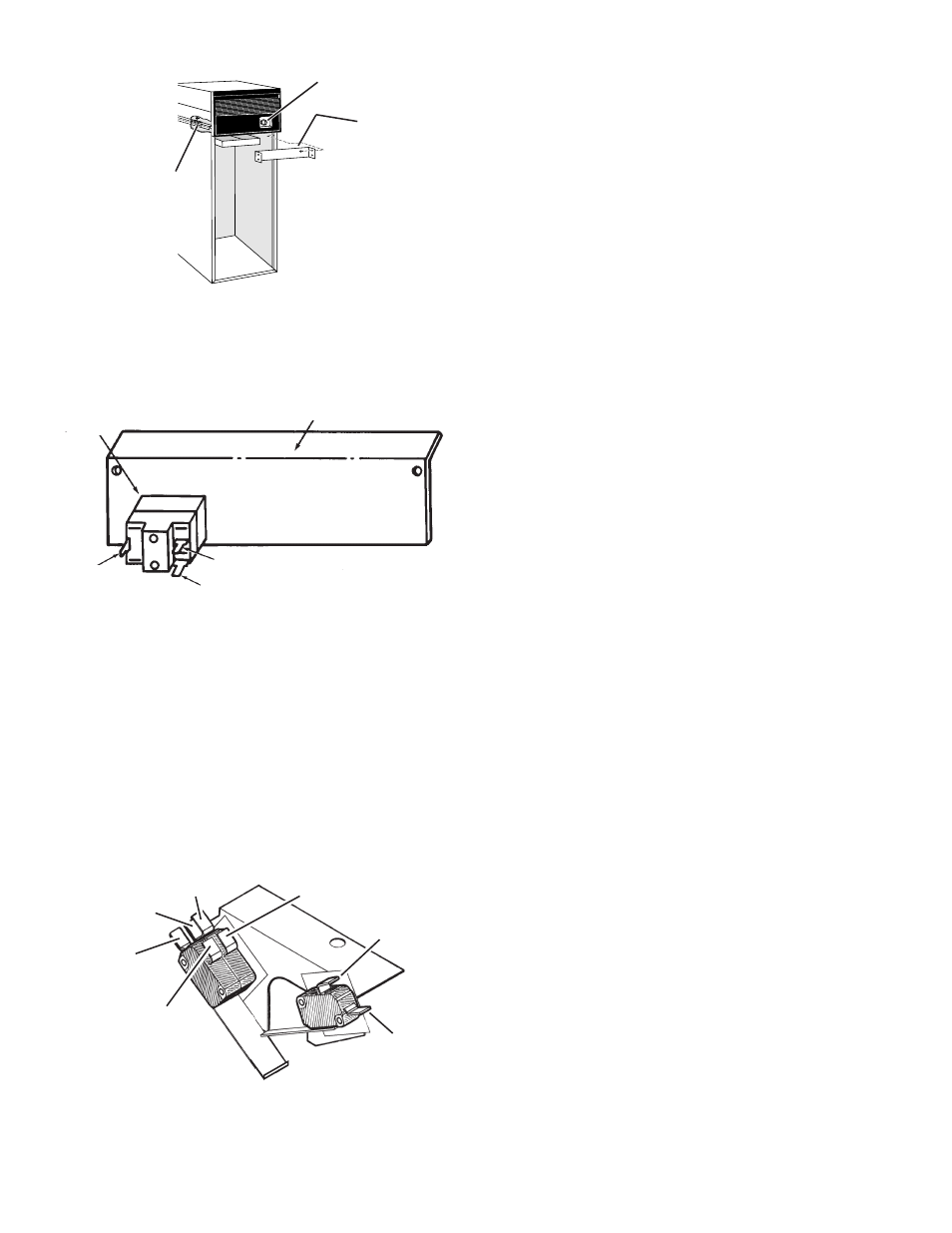

SWITCH LOCATIONS

KEY SWITCH

1. Remove control panel.

2. Remove two hex head screws supporting control panel brack-

et with 5/16" socket.

3. Pull bracket out and remove switch.

UPPER LIMIT SWITCH

1. Remove drawer assembly.

2. Lower ram to gain access to switch.

3. Remove air scentry tray.

4. Remove hex head screw with 5/16" socket, pull switch down

and disconnect wires.

Check

Switch not

Switch

Continuity

Activated

Activated

3 to 1

closed

open

2 to 1

open

closed

6 to 1

open

open

3 to 4

open

open

6 to 4

closed

open

5 to 7

open

closed

INTERLOCK SWITCH

The interlock switch is a single-pole, single-throw momentary

type. It is located on the right side behind the air scentry panel.

Its contacts are normally open. the contacts close when the door

is closed. It is activated by the actuator located on the back of

the door. Another switch located against the interlock switch is

to provide the “No-Jam” circuitry function. This switch is nor-

mally open and bypasses the interlock to provide “No-Jam”

capability. It can be replaced in the same manner as the inter-

lock switch.

TO REPLACE INTERLOCK SWITCH

1. Remove air scentry panel assembly.

2. Disconnect leads one by one and attach to new switch.

TRUNNION NUT

1. Remove back panel, drawer assembly and air scentry panel.

2. Lower ram manually to approx. 10-1/2" from the bottom

assembly onto box or stand described in “CABINET RE-

PLACEMENT/POWER PACK REMOVAL” section.

3. Remove screws from nut retainer.

4. Raise ram assembly slightly by hand and remove nut.

NOTE: Count the number of revolutions to spin off nut. TRUN-

NION must be reinstalled to same position.

5. Reinstall trunnion nut and retainer.

CONTINUAL STRIPPING OF TRUNNION NUT:

POSSIBLE CAUSES:

1. Incorrect assembly of trunnion assembly.

2. Transporting compactor incorrectly.

3. Burr on main drive screw; sharp edge on lead-in thread.

4. Upper limit switch adjustment.

REMOVING PLASTIC BAGS FROM

TRUNNION NUT

Only the trash compactor bags specifically designed and sold

by Broan for use in the compactor should be used. Regular

plastic garbage bags used in place of the Broan bags may be

drawn into the mechanism. Removal of those bags is not cov-

ered by the warranty.

To remove bag from trunnion nut:

1. Remove back of compactor.

2. If possible to slide drawer slightly, remove the door by slid-

ing out the two hinge pins and then prying the door over the

lip on the drawer.

3. Liberally spray drive screw and trunnion nut with WD-40

R

or similar.

4. Use 15/16" socket, and extension, and a 16" ratchet (for le-

verage) and manually turn the drive screw clockwise. (See

section on manually raising and lowering ram.) By turning

the drive screw clockwise, you will help back the bag out of

the trunnion nut.

5. After removing bag, clean drive screw and regrease it with

wheel bearing grease.

DRIVE SCREW

1. Lower ram manually approximately halfway.

2. Remove sprocket.

3. Remove 1/4" drive pin. Slide off washers.

4. Lift ram, causing drive screw to slide out of the motor trun-

nion bearing. Support motor/gearbox assembly since it is

now free to pivot. Unscrew drive screw from front trunnion

assembly.

KEY

SWITCH

CONTROL PANEL BRACKET

V-BLACK

TR-RED

Y-BLUE

INTERLOCK

SWITCH

KEY SWITCH

UPPER LIMIT

SWITCH

1-STRIPED BLUE

7-BROWN

2-ORANGE

3-VIOLET

6-YELLOW

4-BROWN

5-YELLOW