Bryant SINGLE PACKAGED HEAT PUMP UNITS 657A User Manual

Page 27

f. Reassemble motor into housing. Be sure setscrews are

tightened on motor shaft flats and not on round part of

shaft.

g. Reinstall unit access panel.

4. Restore electrical power to unit. Start unit and check for

proper blower rotation and motor speeds during heating and

cooling cycles.

D.

OUTDOOR COIL, INDOOR COIL, AND CONDEN-

SATE DRAIN PAN

Inspect the outdoor coil, indoor coil, and condensate drain pan at

least once each year. See Unit Top Removal section.

The coils are easily cleaned when dry; therefore, inspect and clean

the coils either before or after each cooling season. Remove all

obstructions, including weeds and shrubs, that interfere with the

airflow through the outdoor coil.

Straighten bent fins with a fin comb. If coated with dirt or lint,

clean the coils with a vacuum cleaner, using the soft brush

attachment. Be careful not to bend the fins. If coated with oil or

grease, clean the coils with a mild detergent-and-water solution.

Rinse coils with clear water, using a garden hose. Be careful not to

splash water on motors, insulation, wiring, or air filter(s). For best

results, spray outdoor coil fins from inside to outside the unit. On

units with an outer and inner (2 row) outdoor coil, be sure to clean

between the coils. Be sure to flush all dirt and debris from the unit

base.

Inspect the drain pan and condensate drain line when inspecting

the coils. Clean the drain pan and condensate drain by removing all

foreign matter from the pan. Flush the pan and drain tube with

clear water. Do not splash water on the insulation, motor, wiring,

or air filter(s). If the drain tube is restricted, clear it with a

“plumbers snake” or similar probe device. Ensure that the auxiliary

drain port above the drain tube is also clear

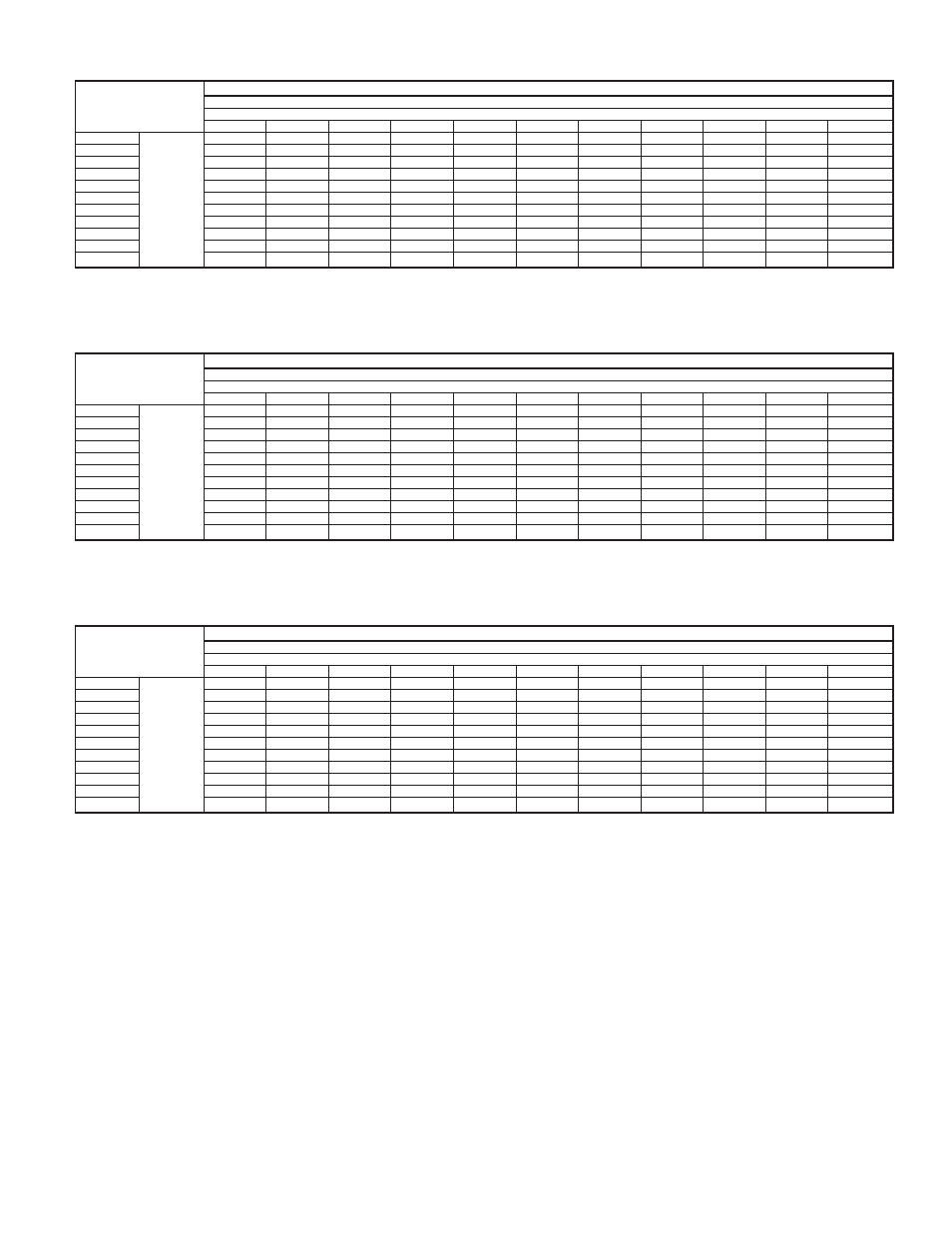

TABLE 13E—SUPERHEAT CHARGING TABLE, UNIT 042

TEMP (F)

AIR ENT

COND

EVAP AIR – CFM

1400

EVAP AIR – Ewb (F)

56

58

60

62

64

66

68

70

72

74

76

65

SPH

13.5

13.5

13.5

17.1

20.7

24.3

25.7

27.1

28.5

27.8

27.0

70

11.4

11.4

11.5

15.1

18.7

22.3

23.6

25.1

26.4

26.1

25.8

75

9.4

9.4

9.4

13.0

16.5

20.1

21.6

23.0

24.4

24.5

24.6

80

8.9

8.9

8.9

12.4

16.0

19.4

21.0

22.4

23.8

24.0

24.0

85

8.2

8.2

8.2

11.8

15.3

18.7

20.2

21.8

23.3

23.4

23.4

90

7.7

7.7

7.7

10.8

13.7

16.7

18.7

20.7

22.7

22.7

22.9

95

7.2

7.2

7.2

9.7

12.2

14.6

17.2

19.7

22.2

22.3

22.3

100

6.6

6.6

6.6

9.6

12.6

15.5

17.6

19.7

21.6

21.7

21.7

105

6.1

6.1

6.1

9.6

13.1

16.5

18.0

19.5

21.1

21.1

21.2

110

—

—

—

7.0

9.9

13.0

15.0

17.1

19.1

19.8

20.6

115

—

—

—

—

6.9

9.4

11.9

14.5

17.0

18.5

20.0

Ewb-Entering Wet Bulb

SPH-Superheat at Compressor (F)

– -Do not attempt to charge system under these conditions as refrigerant slugging may occur.

TABLE 13F—SUPERHEAT CHARGING TABLE, UNIT 048–301

TEMP (F)

AIR ENT

COND

EVAP AIR – CFM

1600

EVAP AIR – Ewb (F)

56

58

60

62

64

66

68

70

72

74

76

65

SPH

26.3

27.0

27.6

28.6

29.6

30.5

30.9

31.3

31.7

31.2

30.7

70

24.0

23.8

23.6

25.0

26.4

27.8

28.4

29.0

29.7

29.6

29.5

75

19.7

19.7

19.7

21.4

23.2

25.0

25.9

26.8

27.6

27.9

28.2

80

15.8

15.8

15.8

17.6

19.4

21.2

22.7

24.1

25.6

26.2

26.9

85

12.0

12.0

12.0

13.8

15.6

17.5

19.5

21.5

23.5

24.5

25.6

90

7.5

7.5

7.5

9.4

11.3

13.2

16.3

19.3

22.4

23.3

24.2

95

—

—

—

5.0

7.0

9.0

13.1

17.1

21.2

22.0

22.8

100

—

—

—

—

—

—

9.4

14.3

19.1

20.3

21.4

105

—

—

—

—

—

—

5.7

11.4

17.1

18.6

20.1

110

—

—

—

—

—

—

—

9.0

13.5

15.8

18.0

115

—

—

—

—

—

—

—

6.7

10.0

13.0

16.0

Ewb-Entering Wet Bulb

SPH-Superheat at Compressor (F)

– -Do not attempt to charge system under these conditions as refrigerant slugging may occur.

TABLE 13G—SUPERHEAT CHARGING TABLE, UNIT 048–311

TEMP (F)

AIR ENT

COND

EVAP AIR – CFM

1550

EVAP AIR – Ewb (F)

56

58

60

62

64

66

68

70

72

74

76

65

SPH

39.4

39.4

40.4

40.6

40.6

40.8

41.0

40.8

40.7

40.2

39.9

70

35.3

35.8

36.8

37.6

37.7

37.8

38.4

38.2

38.4

38.0

37.6

75

31.7

31.4

32.6

34.0

34.5

35.1

35.3

35.5

35.6

35.8

35.5

80

28.1

28.0

28.8

29.8

30.9

31.6

32.8

32.9

32.7

33.0

33.4

85

24.7

24.0

24.6

26.1

27.5

28.3

29.9

30.3

30.5

30.2

30.7

90

21.2

20.8

19.3

21.0

23.4

25.0

26.6

27.4

27.9

28.1

28.0

95

16.5

16.1

16.3

16.5

18.8

21.2

22.7

23.9

25.4

25.7

25.9

100

12.4

7.5

5.6

11.5

14.9

16.8

19.1

21.4

22.0

23.3

23.5

105

—

—

—

—

9.7

12.7

15.2

18.3

19.5

20.2

21.1

110

—

—

—

—

—

7.7

11.2

13.7

16.7

17.8

18.5

115

—

—

—

—

—

—

—

7.3.

10.2

11.8

14.3

Ewb-Entering Wet Bulb

SPH-Superheat at Compressor (F)

– -Do not attempt to charge system under these conditions as refrigerant slugging may occur.

—27—