Caution – Bryant LEGACY 577C User Manual

Page 6

6

Replacing or inspecting filters in units with econom-

izers

Small Chassis (See Fig. 5)

1. Remove return air duct cover at rear of unit using a 5/16--in.

nut driver.

2. Remove the filter(s) by pulling it out and through the unit

duct opening. If filter is dirty, replace both filters with new

ones.

When installing the new filters, note the direction of the airflow

arrows on the filter frame, which should be pointing at the indoor

coil.

3. Reinstall duct cover ensuring opening is air and watertight.

Table 2 – Indoor Air Filter Data with Economizer

Unit Size

Filter Size

30-040/060

2 each 20 x 12 x 1

(508 x 305 x 25 mm)

36-060/090

2 each 20 x 12 x 1

(508 x 305 x 25 mm)

42-060/090

1 each 24 x 14 x 1 (610 x 356 x 25 mm),

24 x 16 x 1 (610 x 406 x 25 mm)

48-090/115/130

1 each 24 x 14 x 1 (610 x 356 x 25 mm),

24 x 16 x 1 (610 x 406 x 25 mm)

60-090/115/130*

1 each 24 x 16 x 1 (610 x 406 x 25 mm),

24 x 18 x 1 (610 x 457 x 25 mm)

*Units with bent indoor coil.

RETURN

DUCT COVER

(Remove for

filter access)

SMALL CHASSIS

A10063

Fig. 5 -- Small Chassis Filter Access

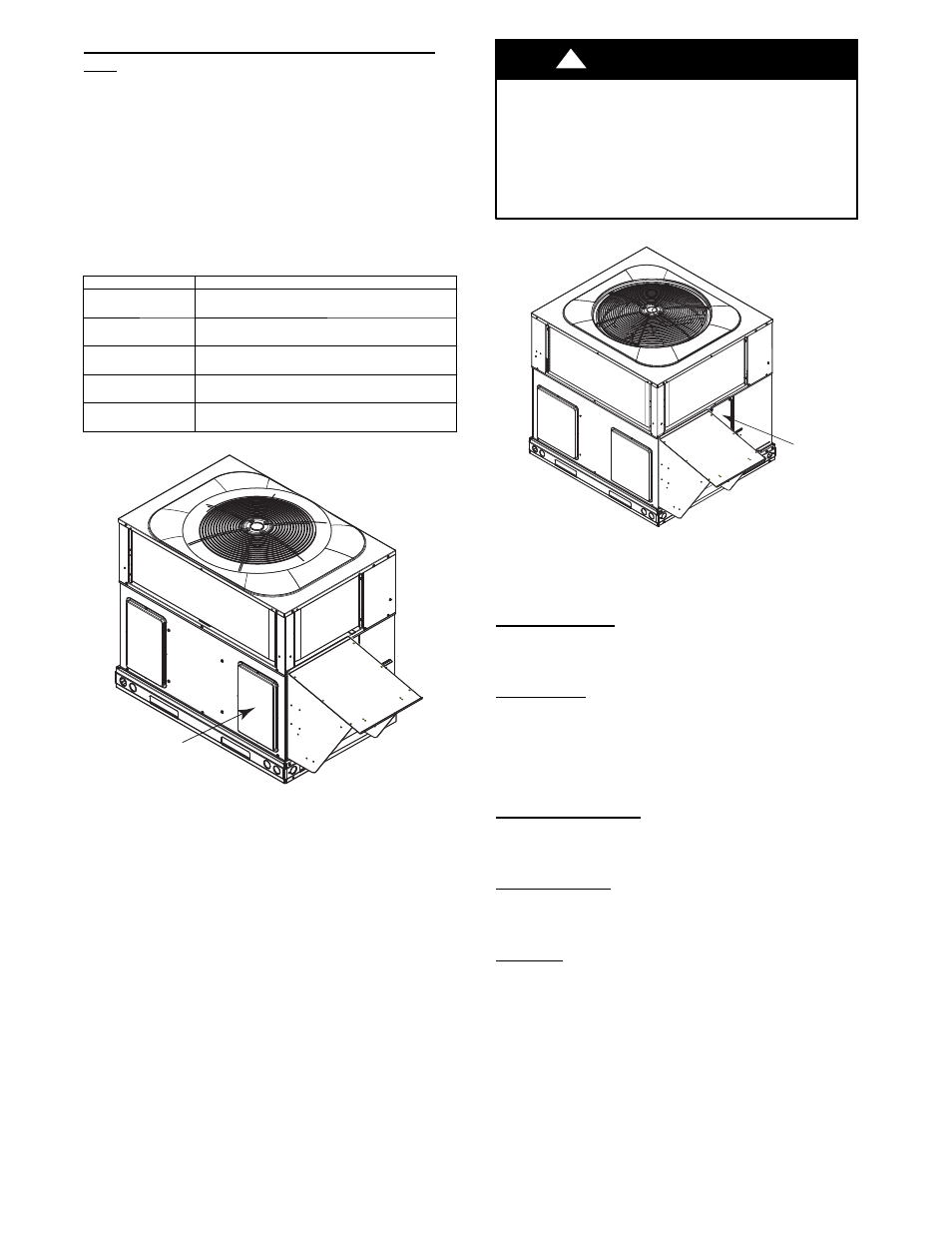

Large Chassis (See Fig. 6)

1. Remove filter access door using a 5/16--in. nut driver.

2. Remove the filter(s) by pulling it out and through the unit

filter access door. If filter is dirty, replace both filters with

new ones.

Units with bent indoor coils, install 24 x 18 x 1 (610 x 457 x 25

mm) filter first and then install 24 x 16 x 1 (610 x 406 x 25) filter.

When installing the new filters, note the direction of the airflow

arrows on the filter frame, which should be pointing at the indoor

coil.

3. Reinstall filter access door ensuring opening is air and water

tight.

UNIT OPERATION HAZARD

Failure to follow this caution may result in

property

damage.

Never operate your unit without filters in place. An

accumulation of dust and lint on internal parts of your unit

can cause loss of efficiency and blower motor and/or

compressor damage.

!

CAUTION

LARGE CHASSIS

FILTER

ACCESS

PANEL

A10062

Fig. 6 -- Large Chassis Filter Access

Fans and Fan Motors

Periodically check the condition of fan wheels and housings and

fan motor shaft bearings. Contact your dealer for the required

annual maintenance.

Heat Exchanger

To ensure dependable and efficient heating operation, the heat

exchanger should be checked by a qualified maintenance person

before each heating season, and cleaned when necessary. This

checkout should not be attempted by anyone not having the

required expertise and equipment to properly do the job. Contact

your dealer for the required periodic maintenance.

Indoor and Outdoor Coils

Cleaning of the coils should only be done by qualified service

personnel. Contact your dealer for the required annual

maintenance.

Condensate

Drain

The drain pan and condensate drain line should be checked and

cleaned at the same time the cooling coils are checked by your

dealer.

Compressor

All compressors are factory shipped with a normal charge of the

correct type of refrigeration grade oil. A compressor should rarely

require additional oil.