Step e, Step d – Bendix Commercial Vehicle Systems TROUBLE SHOOTING COMPRESSOR User Manual

Page 19

Park the vehicle on level ground and chock wheels. Build system pressure to governor

cut-out and allow the pressure to stabilize for one minute.

1: Observe the dash gauges for two additional minutes without the service brakes applied.

2: Apply service brakes for two minutes (allow pressure to stabilize) and observe the

dash gauges.

If you see any noticeable decrease of the dash air gauge readings repair leaks. Repeat

this test to confirm that air leaks have been repaired and return vehicle to service. Please

repeat BASIC test at next service interval. Note: Air leaks can also be found in the charging

system, parking brakes, and/or other components - inspect and repair as necessary.

STEP E

- If No Air Leakage Was Detected In Step D

STEP D -

Air Brake System Leakage Test

STEP C - How to Use the BASIC Test

Oil

Level

Sixty days since last air

tank draining

X

Decision point

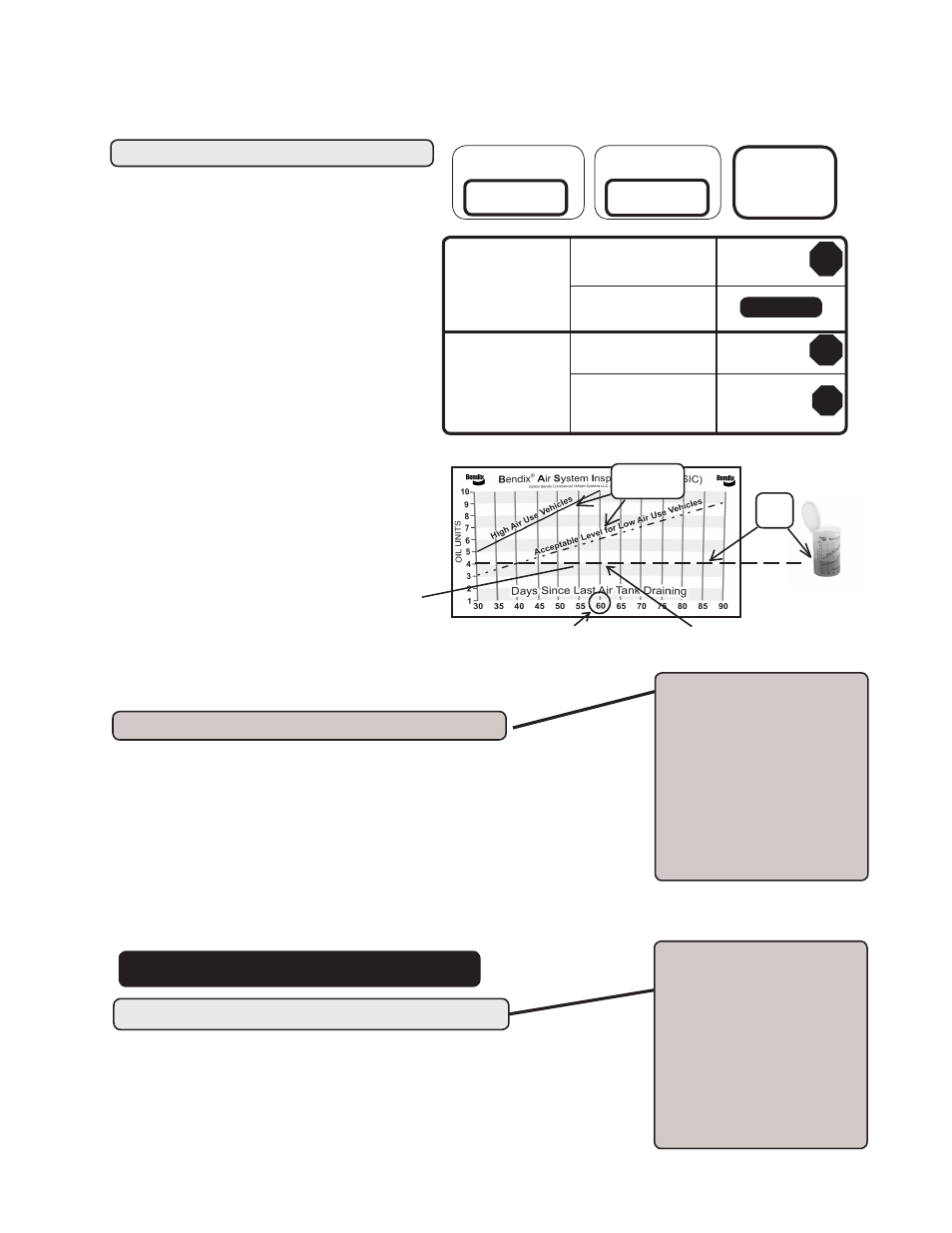

The Technician uses the chart (label) on the BASIC

test cup to help decide the action to take, based on

the amount of oil found. Use the lower acceptance

line for low air use vehicles, and upper line for high

air use vehicles (from Step A).

Acceptance

Lines

If no air leakage was detected, and if you are conducting this

test after completing Step C, go to Step E.

BASIC Test Example

An oil level of 4 units in a sixty-day period is within the

acceptance area (at or below the line) for both low and

high air use vehicles. Return the vehicle to service.

1. Record days since air

tanks were last drained.

3. Action to take

2. Record amount

of oil found:

If number of days is:

30-60 days (high air

use) or

30-90 days (low air use)

if oil level is at or below

the acceptance line for

number of days

if oil level is above

acceptance line for number

of days

System OK.

Return to service.

Otherwise . . .

(if the number of days is

unknown, or outside the

limits above)

if oil level is at or below

30-day acceptance line

if oil level is above 30-day

acceptance line

STOP

TEST

Stop inspection.

Test again

after 30 days.

See Footnote 2.

_________ days

_________ units

Go to Step D

System OK.

Return to service.

STOP

TEST

STOP

+ CK.

The Technician looks for the point where the number

of days since the air tanks were drained meets the

oil level. If it is at or below the (low or high use)

acceptance line, the vehicle has passed the test. If

the point is above the line, we go to the leakage test.

Air leakage is the number

one cause of compressors

having to pump excessive

amounts of air, in turn run

too hot and pass oil vapor

along into the system. Here

the Technician conducts a

four-minute test to see if

leakage is a problem with

the vehicle being tested.

The Technician only

reaches Step E if the

amount of oil found, for the

amount of time since the

air tanks were last drained

exceeds the acceptance

level, AND the vehicle

passes the four-minute

leakage test (no noticeable

leakage was detected).

19

Replace the compressor.

Note: If the compressor is within warranty period,

please follow standard warranty procedures. Attach

the completed checklist to warranty claim.

Filling in the Checklist for the

Bendix

®

Air System Inspection Cup (BASIC) Test

Note: Follow all standard safety precautions. For vehicles using a desiccant air dryer.

Appendix continued: Information about the BASIC Test Kit (Bendix P/N 5013711)