Technical information – Bendix Commercial Vehicle Systems WS-24 ANTILOCK WHEEL SPEED SENSOR User Manual

Page 2

2

ANTILOCK CONTROLLER

& RELAY

WS-24

™

SPEED SENSORS

EXCITER

WHEELS

FRONT WHEEL

REAR WHEELS

The number of AC cycles per revolution of the vehicle's

wheel depends on the number of teeth in the exciter, which

is programmed into the antilock controller. Using the

programmed data, the controller can calculate "vehicle

speed" by analyzing the frequency of AC cycles sent by the

speed sensor. (The frequency of AC cycles is directly

proportional to wheel speed.) See Figure 4.

AC voltage is also proportional to speed, but voltage is not

used to determine speed. It is only an indication of AC

signal strength. The amount of AC voltage generated by a

specific speed sensor depends on the distance, or "gap"

between the tip of the sensor and the surface of the exciter.

Voltage increases as the sensor gap decreases.

Typically, the WS-24

™

sensor is installed in mounting blocks

that are welded to the axle housing. (See Figure 2.)

WS-24

™

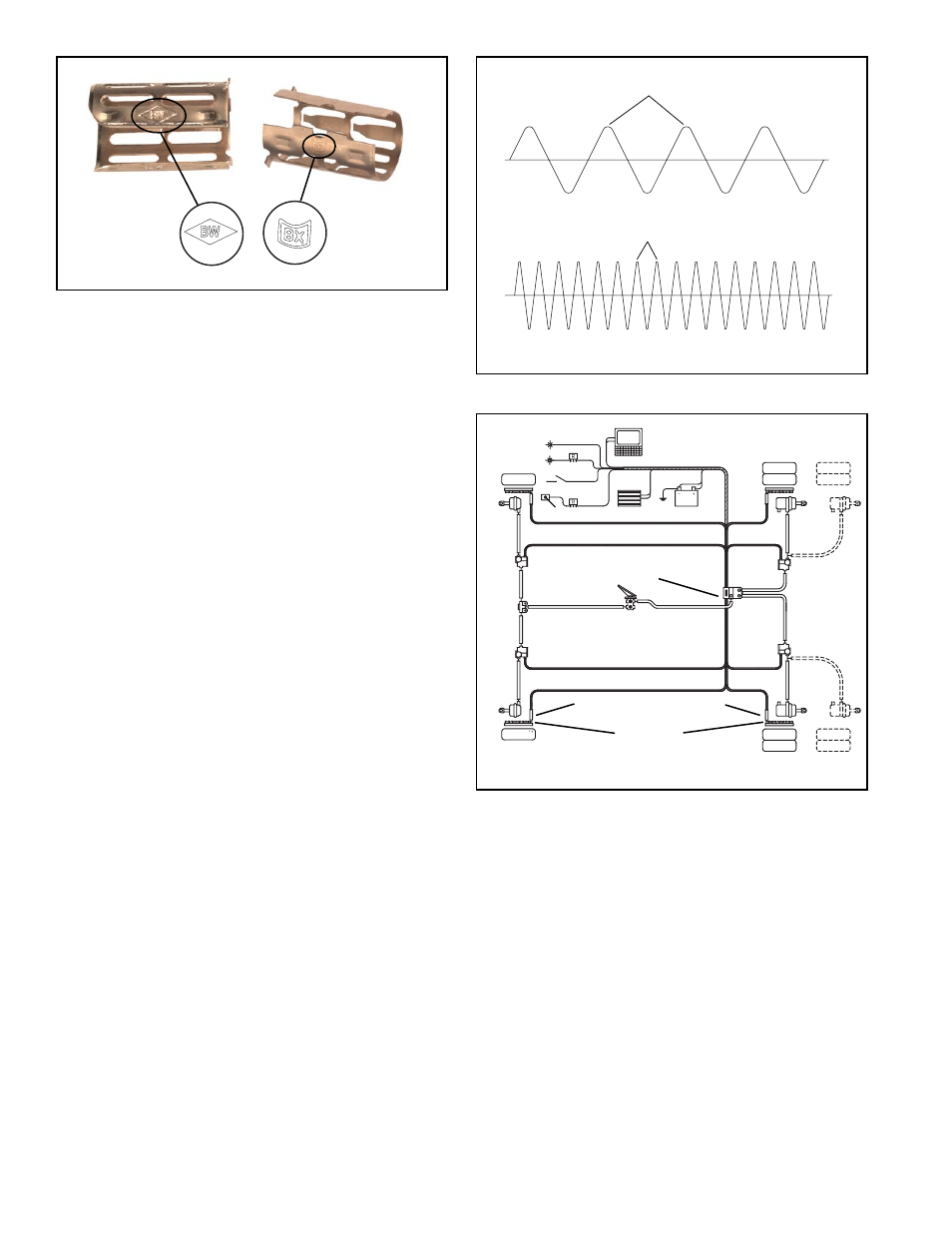

wheel speed sensors are protected by a stainless

steel sheath. They are designed to be used with beryllium-

copper clamping sleeves (sometimes referred to as a

“retainer bushing”, “friction sleeve” or “clip”) (See Figure 3).

The clamping sleeve provides a friction fit between the

mounting block bore and the WS-24

™

sensor.

Please note that WS-24

™

wheel speed sensors must use

clamping sleeve p/n 5012878 instead of p/n 5006849 (used

for previous wheel speed sensors). Always use correct

clamping sleeves to avoid problems associated with reduced

retention force, such as sensor movement and resulting

ABS trouble codes.

The friction fit allows the WS-24

™

sensor to "slide" back

and forth under force but to retain its position when the

force is removed.

When the WS-24

™

sensor is inserted all the way into the

mounting block and the wheel is installed on the axle, the

hub exciter contacts the sensor, which pushes the sensor

back. Also, normal bearing play will "bump" the sensor away

from the exciter. The combination of these two actions will

establish a running clearance or air gap between the sensor

and exciter.

FIGURE 4 - SPEED SENSOR VOLTAGE CYCLE OUTPUT

PEAK TO PEAK

PEAK TO PEAK

HIGH SPEED

LOW SPEED

TECHNICAL INFORMATION

Electrical connector

2 Pin.

Sensor resistance

1500-2500 ohms

Output voltage

At

a

minimum of 100Hz

(approximately 7 mph) the sensor

output across the leads should be

0.400 VAC.

Sensor gap

0 to 0.015 inch.

Sensor body

Outer diameter is 0.627 inch.

Normal resistance

1500-2000 Ohms.

range across pins

(Note: Previous model WS-20

™

at room temperature

sensor was rated at 2000-2500

Ohms.)

FIGURE 5 - TYPICAL ANTILOCK SYSTEM

FIGURE 3 - CLAMPING SLEEVES

P/N 5006849

P/N 5012878

CORRECT

CLAMPING

SLEEVES

HAVE “BX” IN

A SWOOSH

SYMBOL

PREVIOUS

CLAMPING

SLEEVES HAVE

“BW” IN A

DIAMOND