Bendix Commercial Vehicle Systems AD-1 AND AD-2 AIR DRYERS 7/04 User Manual

Page 7

7

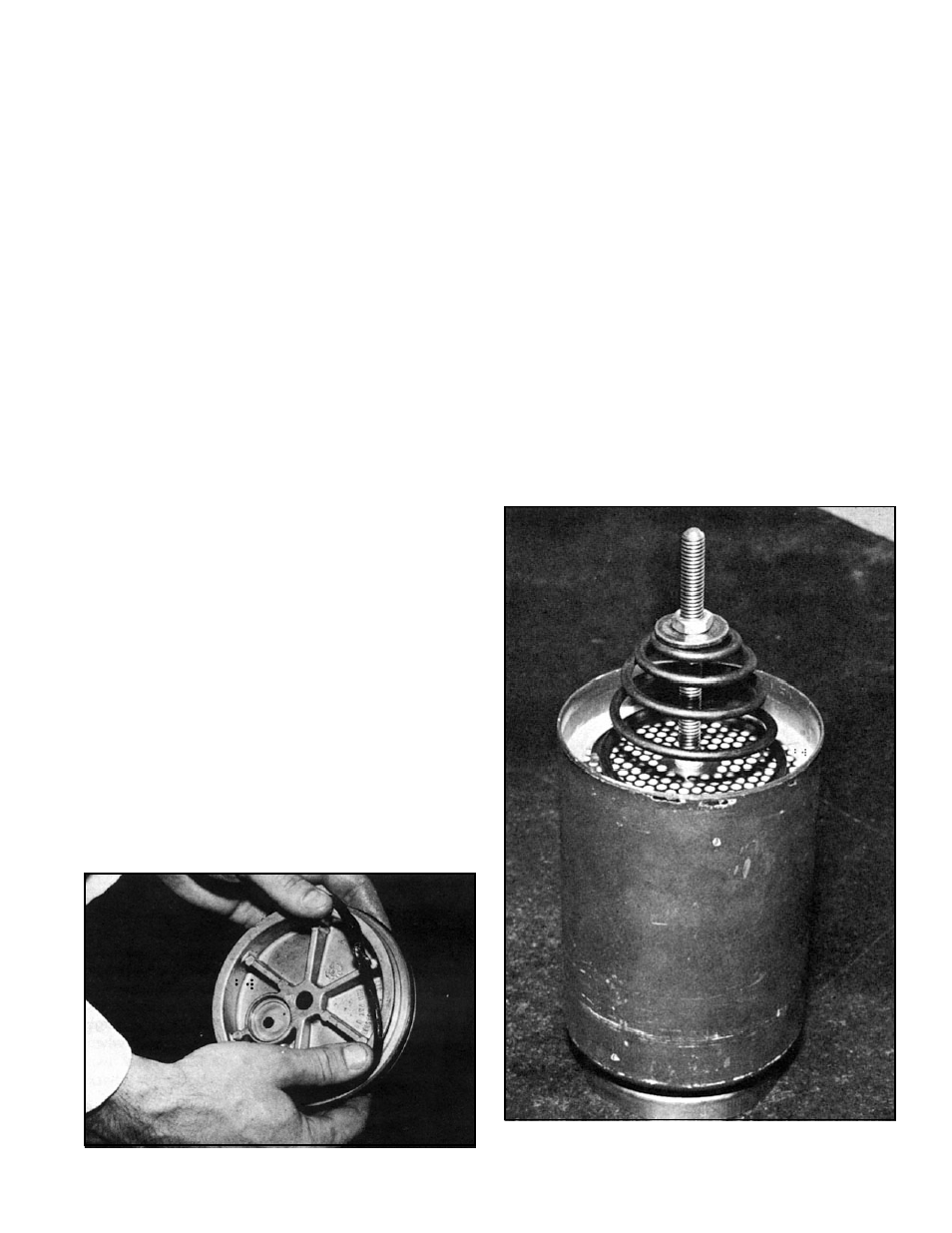

FIGURE 7 - REPLACEMENT DESICCANT CARTRIDGE

FIGURE 6 - DESICCANT SEALING PLATE

End Cover Removal

1.

Loosen the three cap screws on the end cover and turn

the retaining clamps aside (cap screws may be left

finger tight).

2.

Locate the notch in the air dryer shell. While pushing the

end cover up into the dryer, insert the blade of a

screwdriver in the notch and slowly pry out the retaining

ring. If the cartridge bolt has loosened the cartridge

spring may exert a force on the end cover retaining ring

making removal of the retaining ring and end cover

difficult. This spring force will prohibit the end cover

moving up into the dryer shell when pushed up. Warning:

This same force can also cause the end cover to come

out of the air dryer shell unexpectedly during the removal

process. Exercise extreme caution to prevent bodily

injury.

3.

Do not stand or lay directly under the end cover while

servicing. Assure adequate clearance between the end

cover and other surfaces to prevent hand injury if the end

cover dislodges rapidly during removal. NOTE: BE

CERTAIN THE DESICCANT SEALING PLATE

ASSEMBLY COMES OUT WITH THE CARTRIDGE.

CAUTION: Before attempting to remove the desiccant

sealing plate, measure the cartridge bolt from

the top of the desiccant plate lock nut to the

end of the bolt threads. If that measurement is

approximately 3-3/16 inches, proceed with the

disassembly.

If the bolt measures approximately 1-9/16

inches, disassemble using CAUTION.

Approximately 75 pounds of spring force will

remain against the desiccant plate when the lock

nut reaches the end of the bolt thread and is

removed.

REMOVING AND REBUILDING THE AD-1

™

AND

AD-2

™

AIR DRYER DESICCANT SEALING PLATE

Before the desiccant cartridge can be replaced or rebuilt

the desiccant sealing plate must be removed. It is

recommended that all non-metallic parts be replaced when

the plate is removed. In the past, three methods have been

employed, to secure the desiccant sealing plate to the

desiccant cartridge: a Tru Arc retaining ring, two special

thin nuts, and the latest method, a single hex lock nut.

Removing the securing device will permit the desiccant plate

to be separated from the desiccant cartridge. After removing

the desiccant cartridge:

1. Remove the two o-rings from the desiccant plate and

discard them.

2. Remove the ball check valve retaining clip and remove

and discard the rubber ball valve.

3. Clean the desiccant plate thoroughly using a quality

commercial solvent, making sure the purge orifice and

check valve seat are clean.

4. Install a new ball check valve and replace the retaining

clip and screw (Figure 5).

5. Thoroughly lubricate the two new o-rings and install them

in their respective grooves in the purge plate (Figure 6).

6. Set the desiccant sealing plate aside for reinstallation

on the desiccant cartridge.