Operation – Bendix Commercial Vehicle Systems R-12DC DBL CHECK RELAY VALVE 3/07 User Manual

Page 2

2

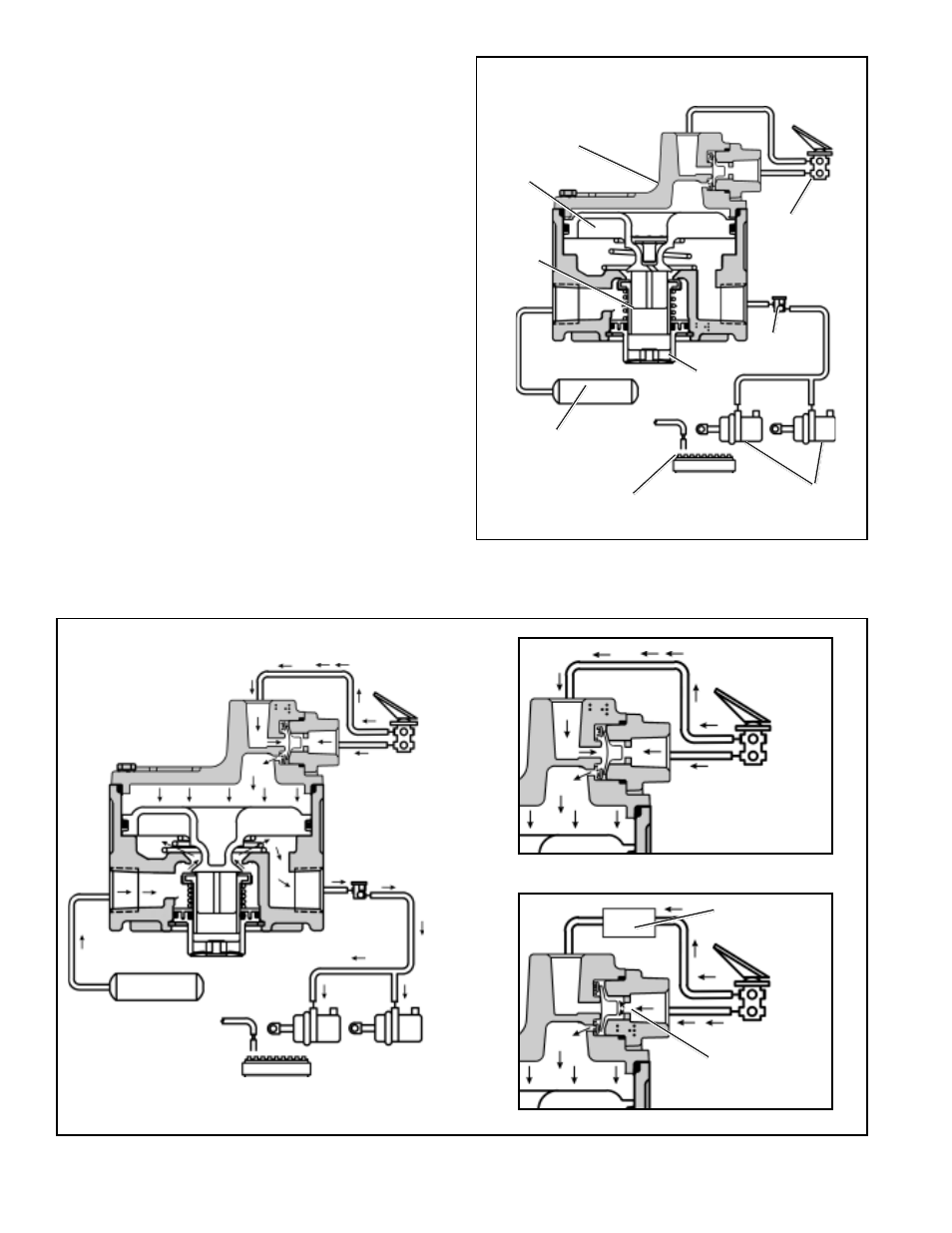

OPERATION

APPLICATION

Under normal conditions, the internal biased double check

valve assures that the primary service signal controls the

valve. Air pressure delivered to the primary service port

enters the small cavity above the piston and moves the

piston down. The exhaust seat moves down with the piston

and seats on the inner or exhaust portion of the inlet/exhaust

valve, sealing off the exhaust passage. At the same time,

the outer or inlet portion of the inlet/exhaust valve moves

off its seat, permitting supply air to flow from the reservoir,

past the open inlet valve and into the service brake

chambers. In the event of a loss of the primary service

line, (see Figure 4) the double check valve mechanism in

the cover of the R-12DC

™

valve will move, shutting off the

primary service line, and instead allow the secondary service

line to apply the air pressure needed to operate the valve.

Note: Secondary service line may leak out of the primary

service at control pressures up to 20 psi when the primary

signal is not present.

BALANCE

The air pressure being delivered by the open inlet valve

also is effective on the bottom area of the relay piston.

BRAKES

APPLIED

FIGURE 4 - R-12DC

™

APPLIED POSITION (SHOWING BIASED DOUBLE CHECK OPERATIONAL VIEWS)

SECONDARY

CONTROL LINE

SUPPLIES RELAY

PISTON

CONTROL LINE

FAILURE

NORMAL: BIASED

DOUBLE-CHECK VALVE

ALLOWS PRIMARY

CONTROL LINE SUPPLIES

RELAY PISTON

BRAKE PEDAL

APPLIED

BRAKE PEDAL

APPLIED

BRAKE PEDAL

APPLIED

R-12DC

™

VALVE

ANTILOCK SENSOR

TONE RING

ANTILOCK

MODULATOR

BRAKE VALVE

(DELIVERY

LINES ARE

SHOWN)

RESERVOIR

BRAKE

CHAMBERS

FIGURE 3 - R-12DC

™

SECTIONAL VIEW WITH TYPICAL

SYSTEM COMPONENTS

RELAY PISTON

EXHAUST

PORT

INLET

EXHAUST

VALVE