Parking brakes applied, Preventive maintenance, Service checks – Bendix Commercial Vehicle Systems PP-DC PARK CONTROL VALVE 6/07 User Manual

Page 2: Pp-dc, Park control valve

2

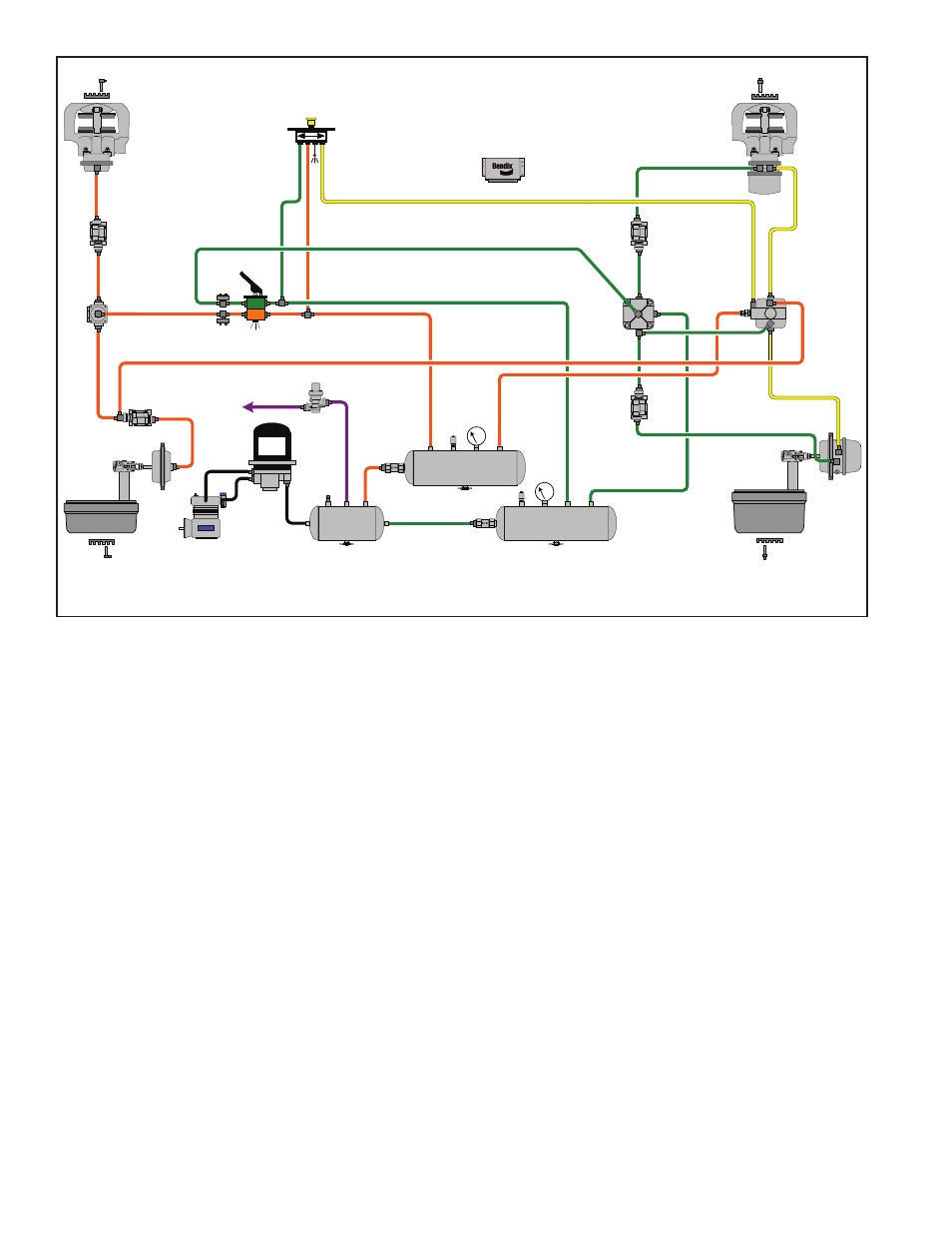

FIGURE 2 - TYPICAL 4 X 2 TRUCK SCHEMATIC WITH BENDIX

®

PP-DC

®

PARK CONTROL VALVE

Note that Figure 3 shows the primary service reservoir

supplying the Bendix

®

PP-DC

®

valve. The double check

valve diaphragm has sealed the secondary reservoir supply

port and allows air to pass from the primary reservoir into

the PP-DC valve.

If primary service reservoir pressure drops below secondary

service reservoir pressure, the double check valve reacts

as shown in Figure 4. It seals the primary service reservoir

supply port and supplies the Bendix PP-DC park control

valve with air from the secondary service reservoir. The

push-pull button remains in and the spring brakes remain

released.

PARKING BRAKES APPLIED

Figure 5 shows the PP-DC valve in the parking-brakes-

applied position. This will occur when the driver manually

pulls out the push-pull button, or when the total system

pressure drops to below 20 to 40 psi.

As shown in Figure 6, when the button “pops” out, the

exhaust seal moves to open the exhaust port to the

atmosphere, allowing delivery line pressure to exhaust.

The plunger o-ring moves to seal off supply pressure.

Spring brake hold-off air is exhausted through the spring

brake relay valve.

Air disc & drum brake actuation combined on a single axle are shown for pictorial purposes only.

Front

Axle Reservoir

Rear

Axle Reservoir

Supply

Reservoir

Bendix

®

ADB-22X

™

Disc Brake

Bendix

®

EC-60

™

Electronic

Controller

Brake Valve

Air Dryer

Air Compressor

Antilock

Modulator

(4 places)

Service

Relay

Valve

Bendix

®

PP-DC

®

Park Control

Valve

Bendix

®

PR-3

™

/ PR-4

™

Valve

To Accessories

Bendix

®

SR-7

®

Spring Brake

Modulating

Valve

Quick Release

Valve

ADB-22X

™

Disc Brake

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions; as

a result, maintenance intervals may vary. Experience is

a valuable guide in determining the best maintenance

interval for air brake system components. At a minimum, the

PP-DC valve should be inspected every six (6) months or

1500 operating hours, whichever comes fi rst, for proper

operation. Should the PP-DC valve not meet the elements

of the Operational Tests noted in this document, further

investigation and service of the valve may be required.

SERVICE CHECKS

1. Remove any accumulated contaminants. Visually

inspect the valve’s exterior for excessive wear or

physical damage. Repair/replace as nec essary.

2. Inspect all air lines connected to the valve for signs of

wear or physical damage. Repair/replace as necessary.

3. Test air line fi ttings for excessive leakage. Repair or

replace as necessary.