Modulator removal, Modulator installation – Bendix Commercial Vehicle Systems M-12R ANTILOCK MODULATOR User Manual

Page 6

6

8. Use only genuine Bendix

®

replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

MODULATOR REMOVAL

1. Identify, mark, or label all air lines and wiring cables and

their respective connections on the modulator (M-12R

™

)

or modulator/controller assembly (M-12

™

).

2. Disconnect all air lines and wiring.

3. Remove the modulator (M-12R

™

) or modulator/controller

assembly (M-12

™

) from the vehicle.

MODULATOR INSTALLATION

1. Install all air line fittings and plugs. Make certain no thread

sealing material enters the modulator.

2. Install the assembled modulator (M-12R

™

) or modulator/

controller assembly (M-12

™

) on the vehicle.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

™

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

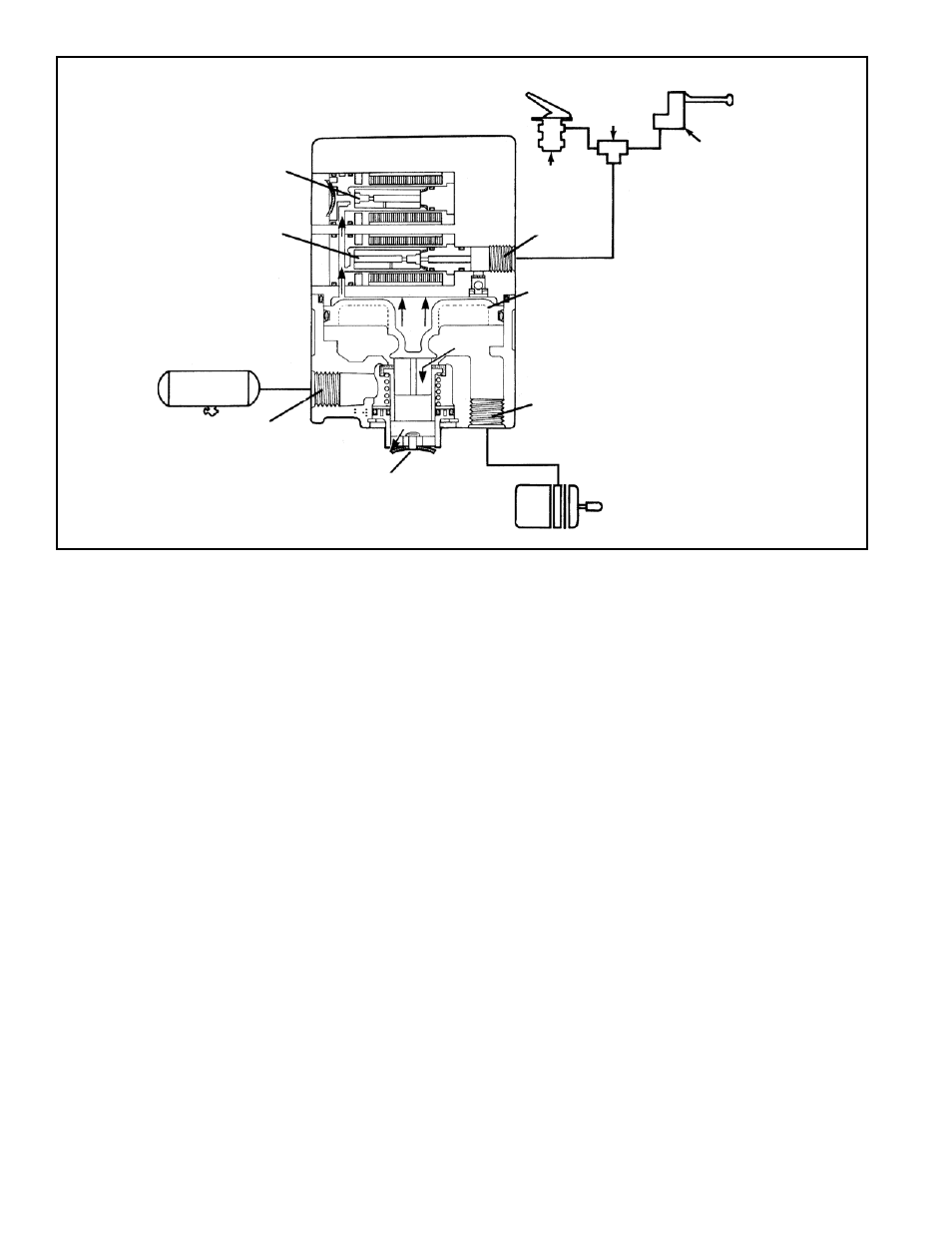

FIGURE 6 ANTILOCK MODE: SOLENOIDS ACTIVATED

DELIVERY

PISTON

EXHAUST

SUPPLY

EXHAUST

SOLENOID

CONTROL

DOUBLE

CHECK

BRAKE

VALVE

SUPPLY

SOLENOID

SERVICE BRAKE

CHAMBER

RESERVOIR

TRAILER

CONTROL