Disassembly – Bendix Commercial Vehicle Systems ASA-5 AUTOMATIC SLACK ADJUSTER 2/11 User Manual

Page 7

7

C. Rotate the manual adjustment hex counterclockwise

until the ASA‑5

®

slack adjuster is clear of the brake

actuator push rod.

Note: Considerably more torque is required to rotate the

manual adjustment hex counterclock wise than is necessary

to rotate it clockwise. The torque may be as high as 70

foot pounds.

2. If the ASA‑5

®

slack adjuster is equipped with the

quick‑connect yoke assembly illustrated in Figure 4:

A. Rotate the ASA‑5

®

slack adjuster's manual

adjustment hex counterclockwise until the brake

actuator push rod just begins to move out of the

actuator.

B. Pinch the legs of the retaining ring together and

pull the ASA‑5

®

slack adjuster away from the brake

actuator push rod until the adapter bushing is free

of the yoke. Remove the retaining ring from the

adapter bushing.

C. Rotate the manual adjustment hex counterclockwise

until the ASA‑5

®

slack adjuster is clear of the brake

actuator push rod.

3. Remove the ASA‑5

®

slack adjuster from the camshaft

of the foundation brake by removing the retaining clip

and any spacers or washers that may be present.

DISASSEMBLY

GENERAL

A reasonable level of cleanliness should be observed when

working on the ASA‑5

®

slack adjuster. Clean the exterior

before disassembly.

The following disassembly and assembly procedure is

presented for reference purposes and presupposes that

a rebuild or repair of the ASA‑5

®

slack adjuster is being

undertaken. Several replacement parts and maintenance

kits are available which do not require full disassembly. The

in structions provided with these parts and kits should be

followed in lieu of the instructions presented here.

1. Clamp the ASA‑5

®

slack adjuster ARM in a bench

vise. Do not clamp across the portion of the body that

contains the adjuster assembly or worm gear. Using a

wire brush, thoroughly clean the exterior of the slack

ad juster paying particular attention to the area around

the manual adjustment hex and its retaining ring. Wipe

all loose contaminants away before proceeding.

2. Remove the cotter pins and washers from the yoke pin

and link pin.

3. Remove the yoke pin and link pin and separate the

yoke from the ASA‑5

®

slack adjuster.

4. If the ASA‑5

®

slack adjuster has a yoke pin bushing,

press it out of the slack adjuster arm.

5. No further disassembly of the ASA‑5

®

slack adjuster is

permitted.

and COMPLETE RELEASES (the number of applications

depends on how much the slack was de‑adjusted).

BRAKE MAINTENANCE INSPECTION

Note: Make certain the vehicle has been prepared

according to the instructions under the heading GENERAL

SAFETY GUIDELINES.

The following test can be used to inspect the maintenance

condition of the foundation brake and to determine how

much of the chamber stroke is caused by the condition of

the foundation brake.

1. Always chock the wheels to keep vehicle from

moving.

2. Raise the axle so the wheel can be rotated.

3. Adjust the slack adjuster to produce light brake drag

with wheel rotation.

4. Apply the brake to 80‑90 psi and measure the stroke

(See Item 3 of In Service Inspection for pressure

tips).

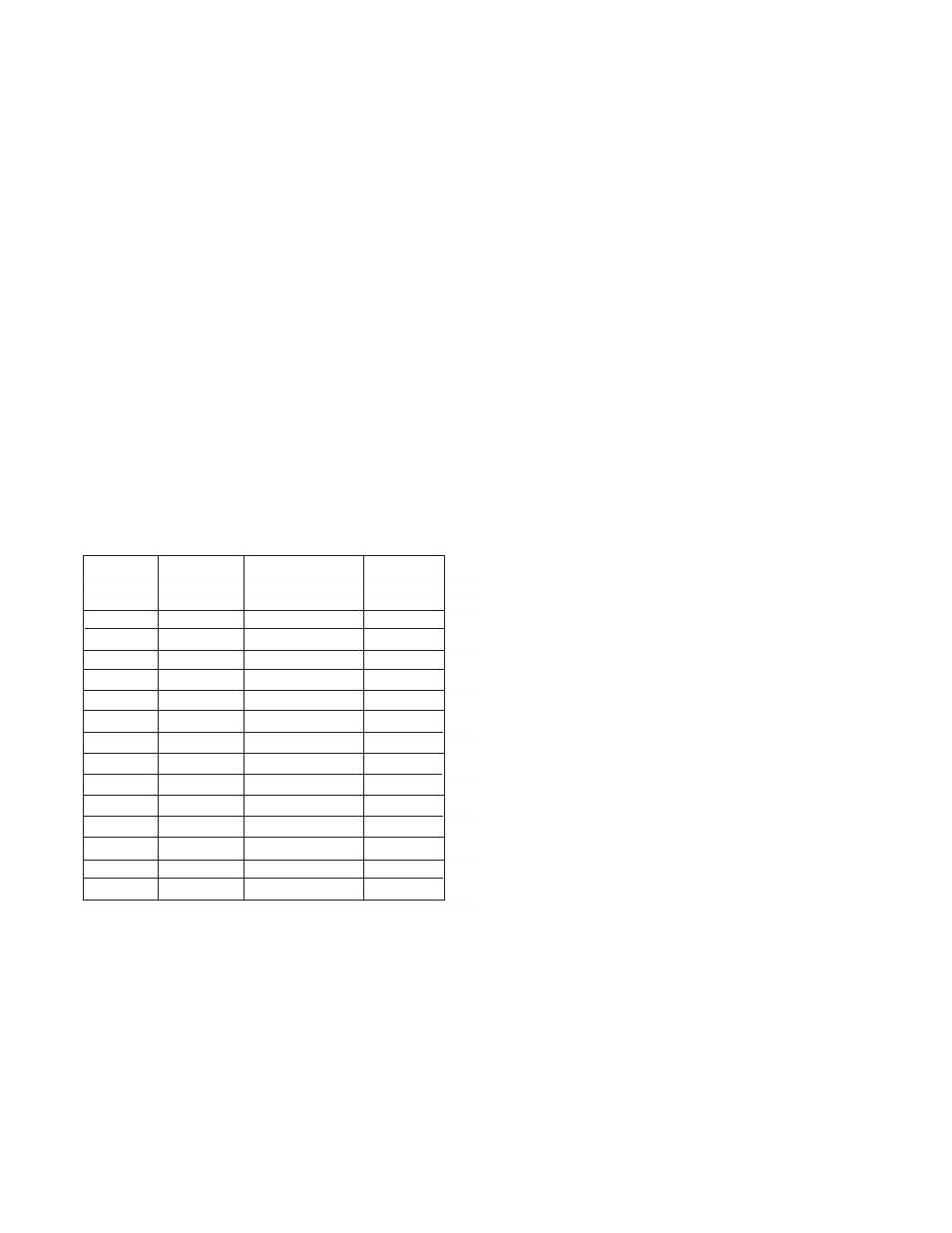

5. If the stroke significantly exceeds the values shown in

the chart, the brake may be out of the norm and brake

maintenance may be required.

AL Factor

15"x4"

16.5"x7"

16.5"x7"

Front

Tractor, Truck

Trailer

Brake

or Bus Brake

Brake

12 X 5.0"

1/2"

N/A

N/A

12 X 5.5"

1/2"

N/A

N/A

16 X 5.0"

5/8"

1/2"

N/A

16 X 5.5"

3/4"

1/2"

N/A

16 X 6.0"

7/8"

5/8"

N/A

20 X 5.0"

5/8"

1/2"

3/8"

20 X 5.5"

3/4"

5/8"

1/2"

20 X 6.0"

7/8"

3/4"

5/8"

24 X 5.0"

N/A

5/8"

1/2"

24 X 5.5"

N/A

5/8"

5/8"

24 X 6.0"

N/A

3/4"

5/8"

30 X 5.0"

N/A

3/4"

5/8"

30 X 5.5"

N/A

7/8"

3/4"

30 X 6.0"

N/A

1"

7/8"

ASA-5

®

SLACK ADJUSTER REMOVAL

Note: Make certain the vehicle has been prepared

according to the instructions under the heading GENERAL

SAFETY GUIDELINES.

1. If the ASA‑5

®

slack adjuster is equipped with the

easy‑on yoke assembly illustrated in Figure 3:

A. Loosen the brake actuator push rod jam nut

and run it back on the brake actuator push rod

ap proximately 5/8 inch.

B. Loosen the easy‑on yoke adapter and run it back

on the brake actuator push rod until it is free of the

yoke.