Bendix Commercial Vehicle Systems QR-N QUICK RELEASE VALVE User Manual

Bendix, Qr-n, Description

1

®

Bendix

®

QR-N

™

Quick Release Valve

SD-03-905

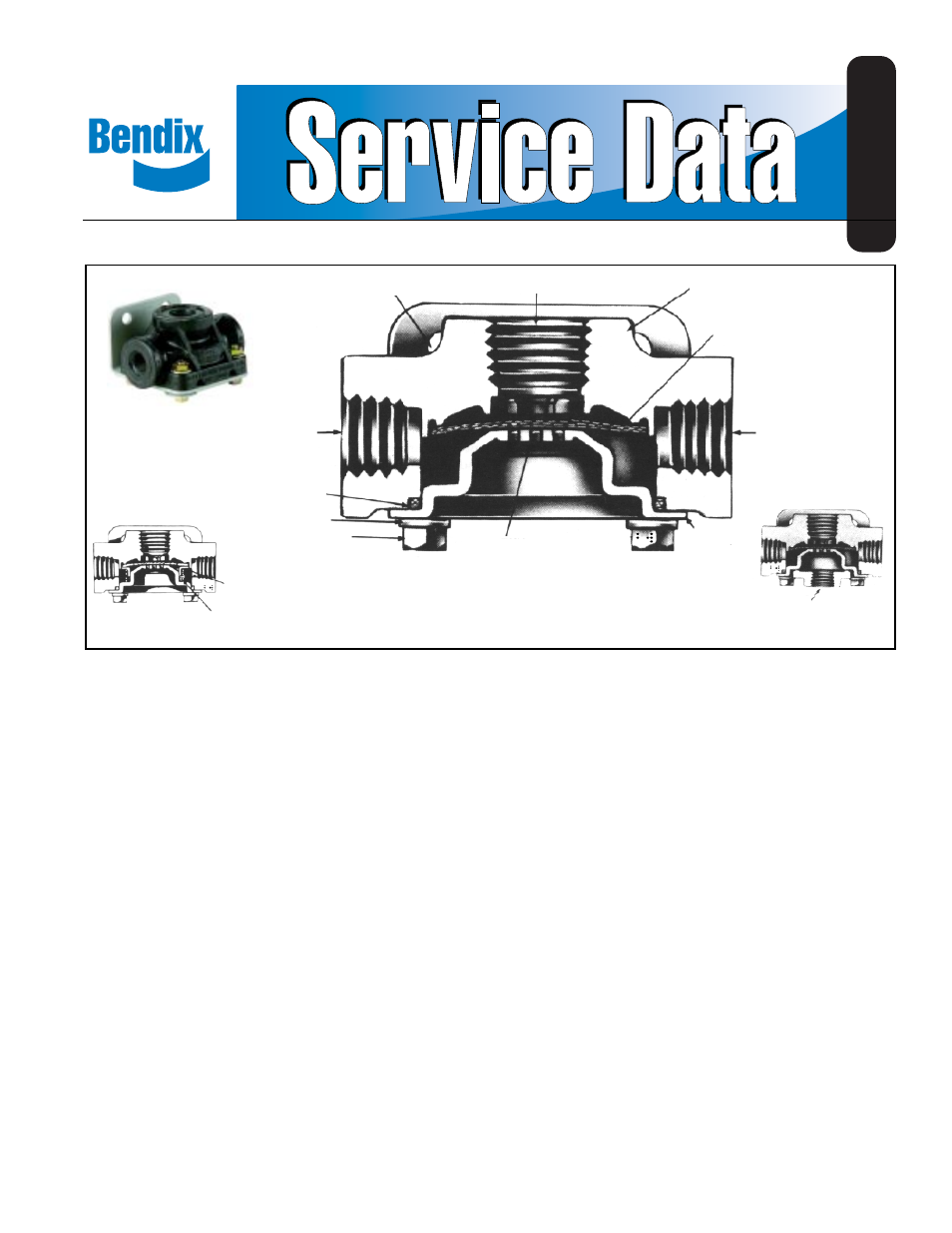

MOUNTING HOLE (2)

SUPPLY PORT

FIGURE 1

EXHAUST PORT

DELIVERY PORT

DESCRIPTION

The function of the Bendix

®

QR-N

™

quick release valve is to

“speed up” the exhaust of air from the actuators it serves. It

is generally mounted on the vehicle axle midway between

the two actuators connected to it.

In the standard (Refer to Figure 1) QR-N

™

valve a flat circular

diaphragm is installed between the nonmetallic upper body

and stamped steel lower body. An o-ring seals the two body

halves which are held together using four 1/4" machine

screws and flange nuts.

In its standard configuration the QR-N

™

valve is supplied

with a 1 psi (6.9 kPa) maximum differential. For example

with supply pressure at 10 psi (68.9 kPa) delivery pressure

is 9 psi (61.8 kPa). Higher differential pressures are available

for special applications and are obtained by the addition of a

spring and diaphragm follower to the standard QR-N

™

valve

(Refer to Insert A). The QR-N

™

valve also comes in sustained

(black body) and non-sustained (gray body) differential

versions.

Various pipe thread sizes are available for the single supply

port and two delivery ports of the QR-N

™

valve. Some versions

of the QR-N

™

valve have a threaded exhaust port. (Refer to

Insert B). QR-N

™

valve mounting is accomplished via two

11/32" diameter holes on 1-1/2" centers.

OPERATION

With no air pressure applied to the QR-N

™

valve (Refer to

Figure 1), the diaphragm is slightly flexed by the upper and

lower body. In this condition the center portion of the

diaphragm rests on the exhaust port in the lower body while

the outer edge and opposite side of the diaphragm rests

against the sealing lip of the upper body.

APPLY

Air entering the supply port of the QR-N

™

valve causes the

center portion of the diaphragm to seal the exhaust port.

Simultaneously, the outer edge of the diaphragm moves away

from the sealing lip of the upper body allowing air to flow

from the supply port out the delivery ports.

BALANCE

When air pressure on both sides of the diaphragm is

approximately equal (1 psi differential), the natural resiliency

of the diaphragm material causes the outer edge of the

diaphragm to move into contact with the upper body sealing

lip. The QR-N

™

valve exhaust remains sealed because air

pressure bears against the center portion of the diaphragm

from one side only.

UPPER BODY

DIAPHRAGM

DELIVERY PORT

SEALING RING

LOCKWASHER

CAP SCREW

SPRING FOLLOWER

DIFFERENTIAL SPRING

THREADED EXHAUST PORT

LOWER

BODY

INSERT B

INSERT A