Tooth design, Jig saw blades, Match the blade to the job – Bosch 4100DG-09 User Manual

Page 18: Blades, Jig saw, High carbon steel (hcs), Bi-metal (bim), Tungsten carbide (tc), High speed steel (hss), Progressor® patented tooth design

70

Boschtools.com

Toll Free: 877-BOSCH-99

Jig Saw

Blades

High Carbon Steel (HCS)

Excellent blades for softer materials such as wood, laminated

particleboard and plastics.

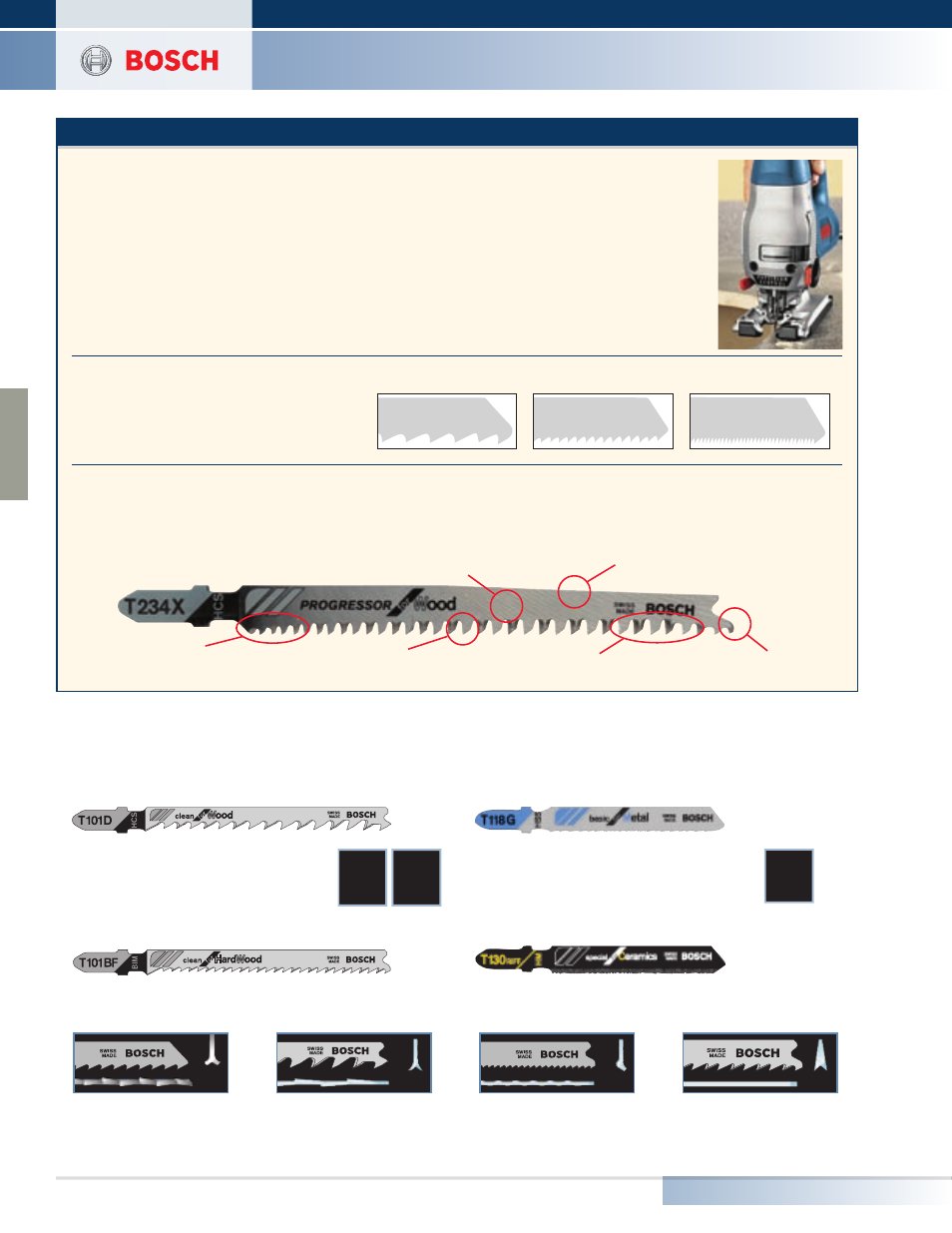

Tooth Design

For fast, rough cuts in wood

and plastics.

Side Set & Milled

For clean, fast cuts in wood

and plastics.

Side Set & Ground

For cuts in metal, non-ferrous

metal, aluminum and plastics.

Wavy Set & Milled

For precise, fine, clean cuts

in wood.

Ground & Taper Ground

Bi-Metal (BiM)

This highly flexible, tough combination of HSS

and HCS results in a blade suitable for the most

demanding applications when there is a risk of

breakage or when extreme flexibility and versa-

tility are required.

Tungsten Carbide (TC)

Use blades with tungsten carbide teeth to cut abra-

sive materials such as reinforced plastics, fiberglass,

cement board and stainless steel. Use blades coated

with tungsten carbide grit to cut abrasive materials

such as tile, glass, cast iron and brick.

High Speed Steel (HSS)

Fully hardened high speed steel blades are ideal for cutting

metal, aluminum and non-ferrous metal.

™

LASTS

THAN

BI-METAL

10X

LONGER

™

THAN HIGH

SPEED

STEEL

LASTS

2X

LONGER

LASTS

10X

LONGER

THAN HIGH

CARBON

STEEL

™

™

LASTS

THAN

BI-METAL

10X

LONGER

™

THAN HIGH

SPEED

STEEL

LASTS

2X

LONGER

LASTS

10X

LONGER

THAN HIGH

CARBON

STEEL

™

Jig Saw Blades

As the world’s largest jig saw tool and blade manufacturer, Bosch understands the demands of cutting materials

quickly, smoothly and precisely. Bosch’s optimized jig saw blade configurations cut precisely and easily in

conventional and specialized materials.

Blade configurations include

Progressor® tooth design for superior performance in speed and cleanliness of cut,

plunge blade tip shapes for easy plunge cutting in wood, longer blades for deep sandwich material cuts and

flexible blades that provide strength in curve and angle cutting.

Bosch makes it easy for you to quickly find the blade that best fits the job with simple

color coding and blade

applications that are identified on each blade. For the professional that requires technical detail, key blade

specifications are provided such as overall length and working length, blade materials, tooth design, angles and

pitch (teeth per inch (

TPI)).

Progressor® Patented Tooth Design

The Progressor® name comes from the progressive tooth pattern that graduates from high to low teeth per inch over the length of the blade.

The progressive tooth pattern is engineered so the blade can cut both thick and thin material cleanly and smoothly. The Progressor® line of

blades are the ideal blades when switching from one material thickness to another, eliminating the need for blade changes and saving time

on the job. Available for wood, metal or all purpose applications.

Teeth (TPI)

Every material has a different thickness. To achieve

the best possible cutting quality and the fastest

cutting time, it is important to match material

thickness with the proper blade geometry.

Always keep 2-3 teeth in material while cutting.

6 TPI

14 TPI

36 TPI

Thin Material

Small Teeth

Thick Material

Large Teeth

Ground Teeth

For superior speed and cleanliness.

Tip Engineered

For easy plunge cuts.

HCS

For flexibility.

Taper Ground

For speed and increased blade life.

Bosch blades are designed with optimal tooth spacing, tooth shape and cutting angle to give you

the best possible speed, cleanliness of cut and optimal performance.

Match the Blade to the Job