Warning – Burnham ALP285 User Manual

Page 3

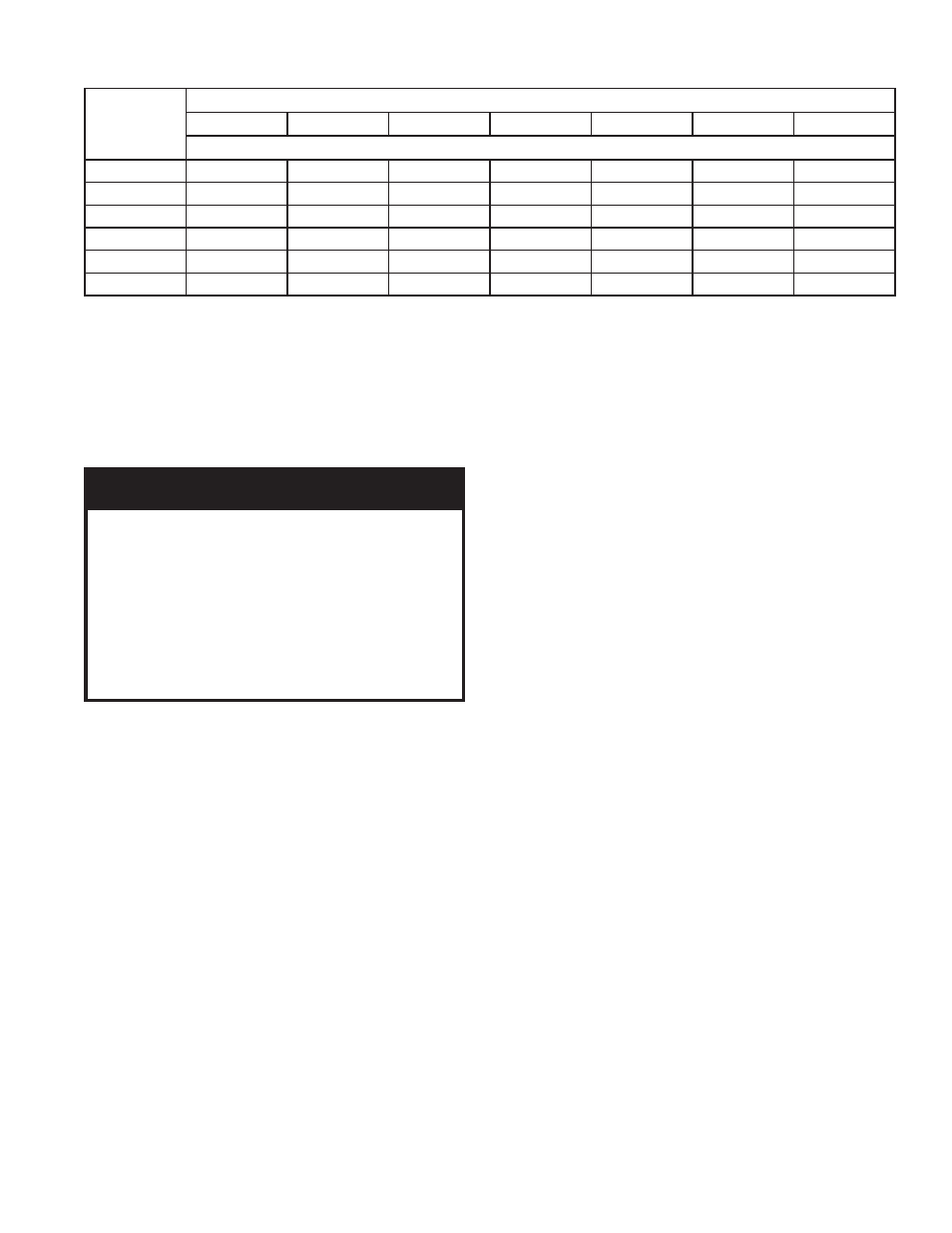

TABle S: MODUlAR BOIleR WATeR MANIFOlD SIzING

Boiler

Model

Number of Units

2

4

5

6

7

8

Recommended Minimum Common Water Manifold Size (NPT)

ALP080

1¼”

1½”

2”

2½”

2½”

2½”

2½”

ALP105

1½”

2”

2”

2½”

2½”

2½”

3”

ALP150

2”

2”

2½”

2½”

2½”

3”

3½”

ALP210

2”

2½”

3”

3”

3½”

4”

4”

ALP285

2½”

2½”

3”

3½”

3½”

4”

5”

ALP399

2½”

3”

3

4”

4”

5”

5”

e.

Gas Piping

1. Refer to National Fuel Gas Code, Local Codes and

Tables 12A and 13 of the Installation, Operating and

Service Instructions for gas pipe sizing.

2. Each boiler must be piped as shown in Figure 26 of

the Installation, Operating and Service Instructions.

WARNING

If gas pressure in the building is above ½ psig,

an additional gas pressure regulator is required.

Using one additional regulator for multiple

boilers may result in unsafe boiler operation.

The additional regulator must be able to properly

regulate gas pressure at the input of the smallest

boiler. If the regulator cannot do this, two or

more additional regulators are required. Consult

regulator manufacturer and/or local gas supplier

for instructions and equipment ratings.

f.

electrical

1. Each boiler must be provided with a fused

disconnect and service switch.

2. Install wiring in accordance with requirements of

authority having jurisdiction. In the absence of such

requirements, follow the National Electric Code,

NFPA 70 and/or CSA C22.1 Electric Code.

G.

Modular Boiler Control Systems

Contact a controls manufacturer such as Honeywell or

Tekmar to properly apply a modular control system.

Common systems may use outdoor temperature, return

water temperature or both to stage the boilers.