Save energy and reduce, Condensate transfer stations, Horizontal boiler feed systems – Bryan Boilers HFS-15-100-100-D User Manual

Page 2

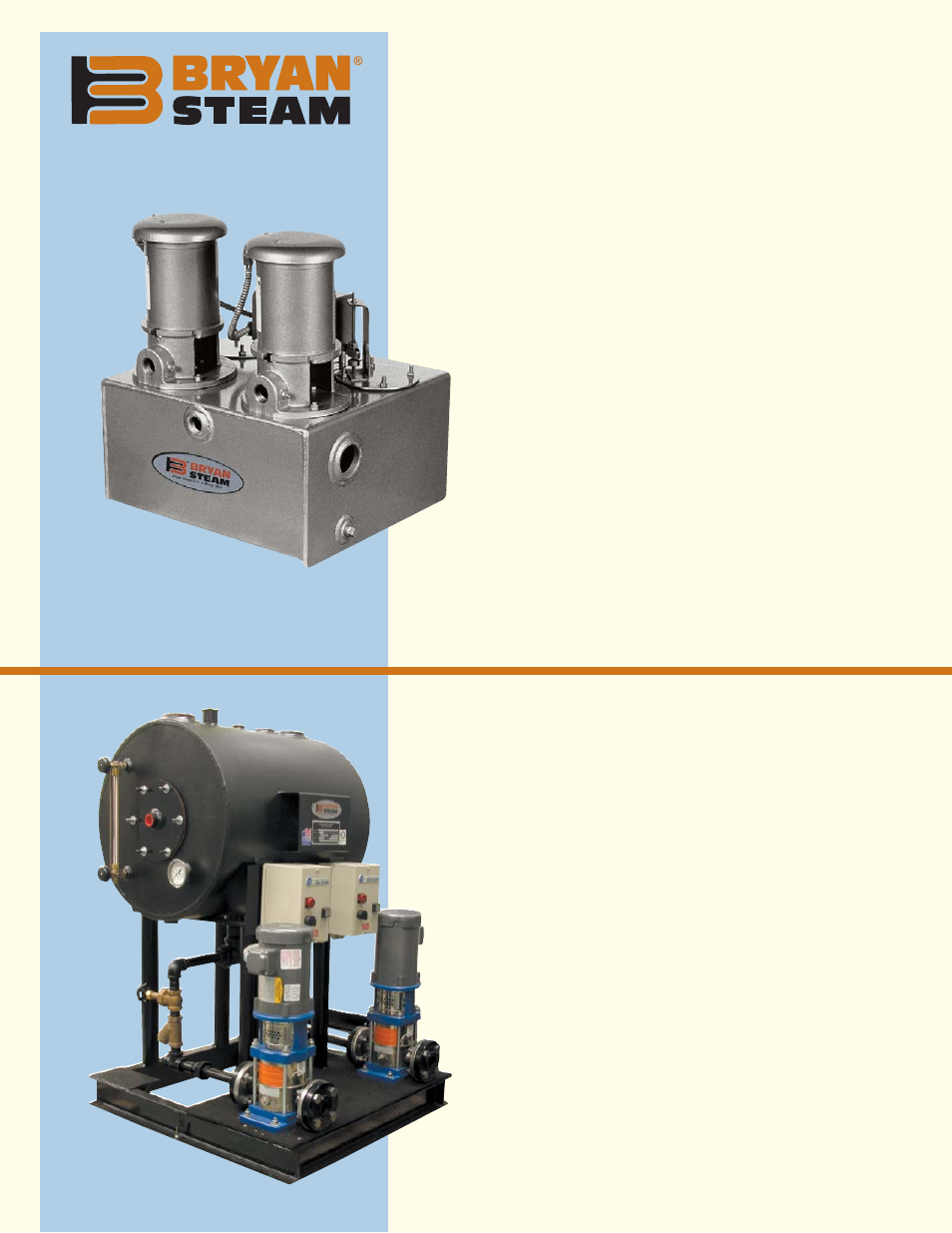

Condensate Transfer Stations

6 to 60 GPM pump capacities

10 to 60 PSI discharge pressures

8 to 50 gallon receivers

In most heating systems, condensate, and sometimes

steam, is trapped out of heaters, kettles, hot presses,

molds, absorbers, and other equipment and drained to

a return unit having given up some of its heat in the

process. If a trap malfunctions, the condensate can be

passed to the return unit at a much higher temperature

causing the return unit to fail. When using Bryan

Condensate Transfer Stations as the return unit, this

problem is overcome because they are designed to

eliminate cavitation at high temperatures. In addition,

Bryan Condensate Transfer Stations are designed to

handle the higher load placed on them during cold

starts and are supplied with reliable pumps that are

designed to handle hotter water and develop higher

pressures at lower speeds.

Bryan Condensate Transfer Stations are ideal for

remote or non-accessible locations where unattended,

dependable performance is essential.

The Bryan horizontal boiler feed system is a conven-

tional stand-mounted feed system that is completely

packaged, but is also flexible to meet each customers

specific needs.

Features

• Atmospheric tank built from heavy ¼" minimum

steel thickness

• Tank sizes from 50 to 500 gallons

• Factory packaged for ease of installation

• Packages based on 1 gallon storage per

1 BHP minimum

• Available with single or multiple pump packages

• Pumps mounted in front of tank for ease of

maintenance and replacement

• TEFC pump motors and NEMA 12 enclosures

are standard

• Heavy duty stand with pump platform

• Integral steam preheater optional

Horizontal Boiler Feed Systems

Capacities to 500 boiler HP

15 through 250 PSI boilers

Save energy and reduce

2

Model B-26S-D

Model HFS-15-100-100-D