Acuum, Aintenance, Homas – Wood’s Powr-Grip MR1611LDCO User Manual

Page 31

Rev 1.0/3-13

29

MR1611LDCO/DVS: #35048

V

ACUUM

P

UMP

M

AINTENANCE

―

T

HOMAS

2907CDC22/12

WARNING: Before proceeding with any maintenance, disconnect power source.

If the vacuum pump takes too long to attain full vacuum, it may require maintenance (see

OPERATING FEATURES for location of pump). Replace the diaphragms, valve flappers or head

gaskets as necessary to obtain acceptable pump performance (see REPLACEMENT PARTS LIST).

Perform the following procedures on both heads of the pump.

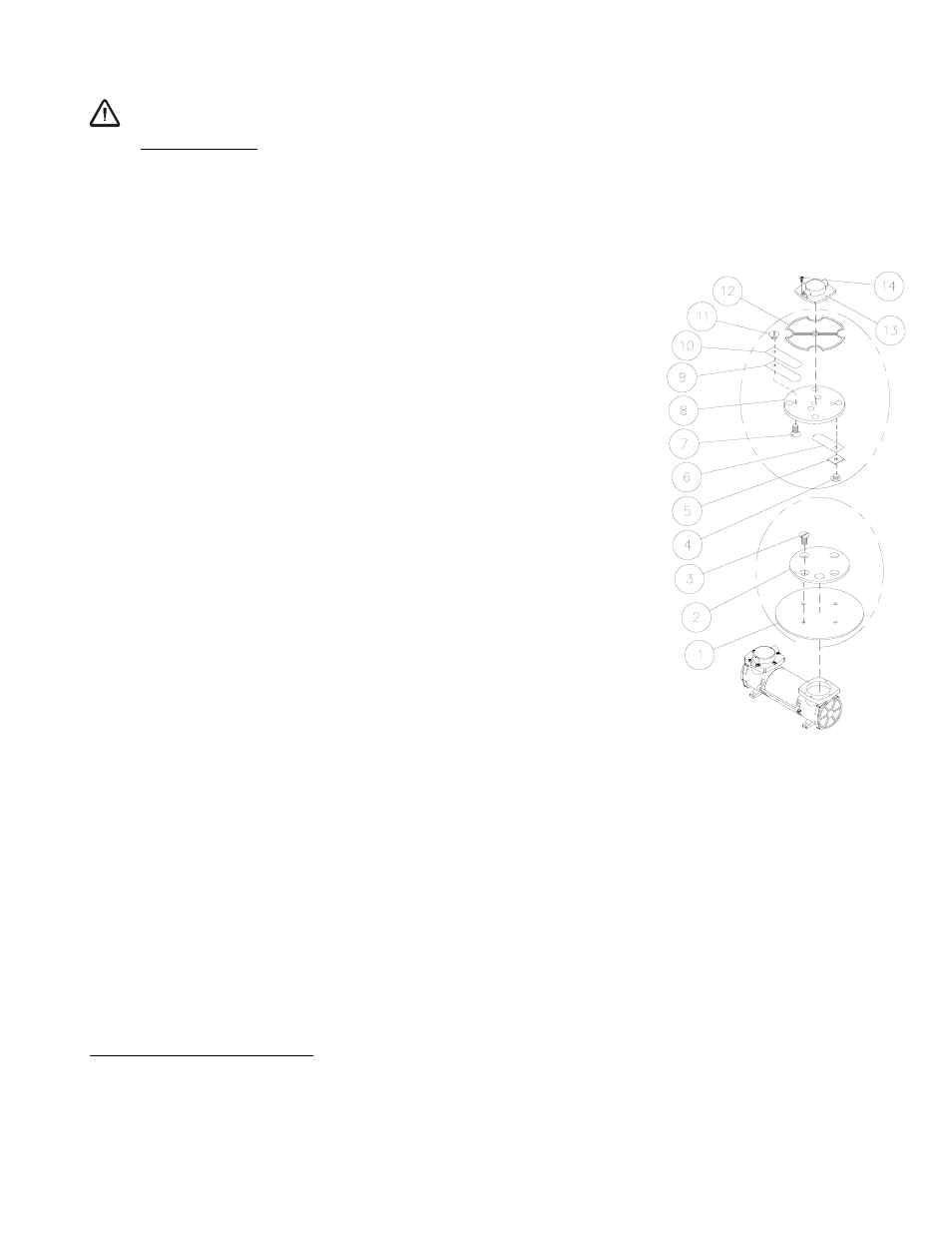

Replacing a Diaphragm (1)

1) Remove the six head screws (14) and remove the head

(13).

2) Remove the four diaphragm hold-down screws (3) and the

diaphragm hold-down plate (2)

.

3) Replace the diaphragm (1) and reverse the above procedure

for reassembly.

Replacing an Intake Valve Flapper (6)

1) Remove the six head screws (14) and remove the head

(13).

2) Remove the intake valve flapper screw (4) and the intake

valve keeper (5).

3) Replace the intake valve flapper (6) and reverse the above

procedure for reassembly.

Replacing a Set of Exhaust Valve Flappers (9 &

10) and a Head Gasket (12)

1) Remove the six head screws (14) and remove the head

(13).

2) Turn the head upside-down and remove the five valve plate screws (7).

3) Lift out the valve plate (8) to access the exhaust valve flappers (9 & 10) and head gasket

(12).

23

4) Remove the exhaust valve flapper screw (11) and replace the exhaust valve flappers.

5) Replace the head gasket and reverse the above procedure for reassembly.

1 DIAPHRAGM

5 INTAKE VALVE KEEPER

10 EXHAUST VALVE FLAPPER (METAL)

2 DIAPHRAGM HOLD-DOWN PLATE

6 INTAKE VALVE FLAPPER (METAL)

11 EXHAUST VALVE FLAPPER SCREW

3 DIAPHRAGM HOLD-DOWN SCREWS

7 VALVE PLATE SCREWS

12 HEAD GASKET

4 INTAKE VALVE FLAPPER SCREW

8 VALVE PLATE

13 HEAD

9 EXHAUST VALVE FLAPPER (PLASTIC)

14 HEAD SCREWS

23

CAUTION: Depending on the product, the vacuum system may require the valve plate (8) to be rotated to an orientation

different from the one shown. When removing the valve plate, always take note of its orientation in the pump head (13), and

install the valve plate the same way during reassembly. In all cases, the valve plate must be oriented so that its intake hole is

matched with the head port that connects to the check valve.