Assembly, Et up the, Ifter – Wood’s Powr-Grip MRTALP611LDC User Manual

Page 9

Rev 10.0/5-14

7

MRTALP6-DC: #35056

ASSEMBLY

T

O

S

ET UP THE

L

IFTER

1) Open the shipping container and remove all materials for restraining or protecting the vacuum

lifter. Save the container for use whenever the lifter is transported.

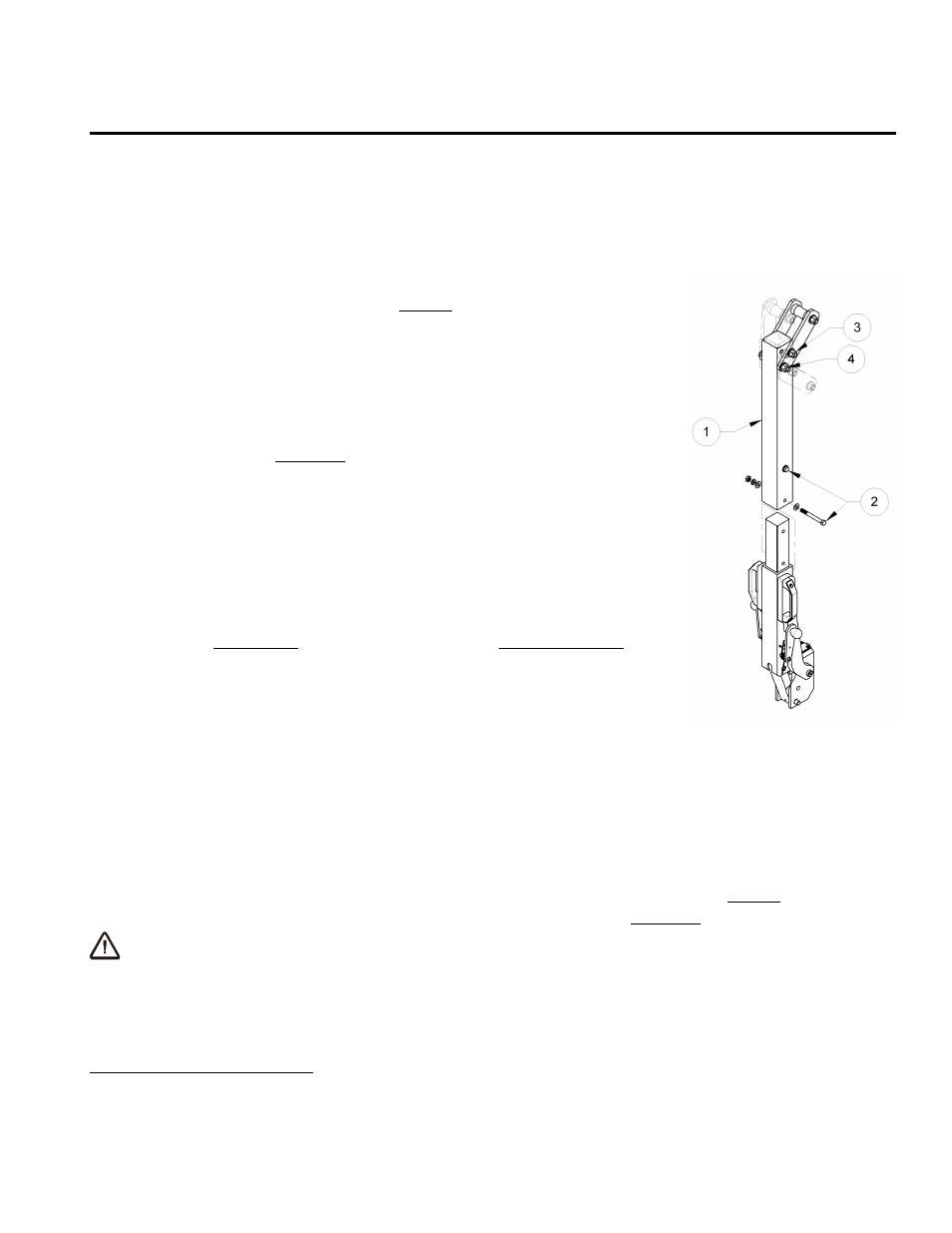

2) If necessary, assemble the lifter's lift bar as follows: One segment

of the lift bar can be removed, to reduce overall lifter dimensions

for shipping. If so, orient the removable segment (1) as shown in

the illustration, and slide it over the other segment until the bolt

holes align. Reinstall the bolts and all associated hardware (2);

then tighten both bolts securely.

3) Position the lifter's lift spool as follows: The adjustable lift spool

assembly provides 3 different lift points (see illustration), in order

to optimize the lifter's hang angle and/or its overall height for the

intended use.

5

To change the lift spool position, remove the

retaining bolt (3) and, if necessary, loosen the pivot bolt (4). Next

pivot the lift spool assembly until the bolt holes align for the

desired spool position. Then reinstall the retaining bolt and all

associated hardware. Tighten both bolts securely.

Note: For pad frame configurations that use extension arms (see

T

O

C

HANGE THE

P

AD

F

RAME

C

ONFIGURATION

to follow), position the lift

spool to avoid contact with the extension arms when the pad frame

is rotating.

4) Suspend the lifter from a crane as follows: Select hoisting equipment (crane and hoist, when

applicable) rated to carry the maximum load weight plus the lifter weight (see

SPECIFICATIONS: Maximum Load Capacity and Lifter Weight).

Note: Any application of the lifter must conform to all statutory or regulatory standards that

relate to the hoisting equipment when used in its geographical location (eg, relevant OSHA

standards in the USA).

Disengage the tilt latch (see OPERATION: T

O

T

ILT THE

L

OAD

) and raise the lift bar to a vertical

orientation. Then attach the hoisting equipment hook to the lift spool.

WARNING: Hoisting equipment hook must be fitted with restraining latch to

prevent lift spool from slipping off under any circumstances.

5

When the extension arms are installed on the pad frame (see illustration in OPERATING FEATURES), placing the lift spool in

the lowest position would create interference when the pad frame is rotated. To avoid this problem, place the lift spool in one of

the other two positions or remove the extension arms (see T

O

C

HANGE THE

P

AD

F

RAME

C

ONFIGURATION

to follow).