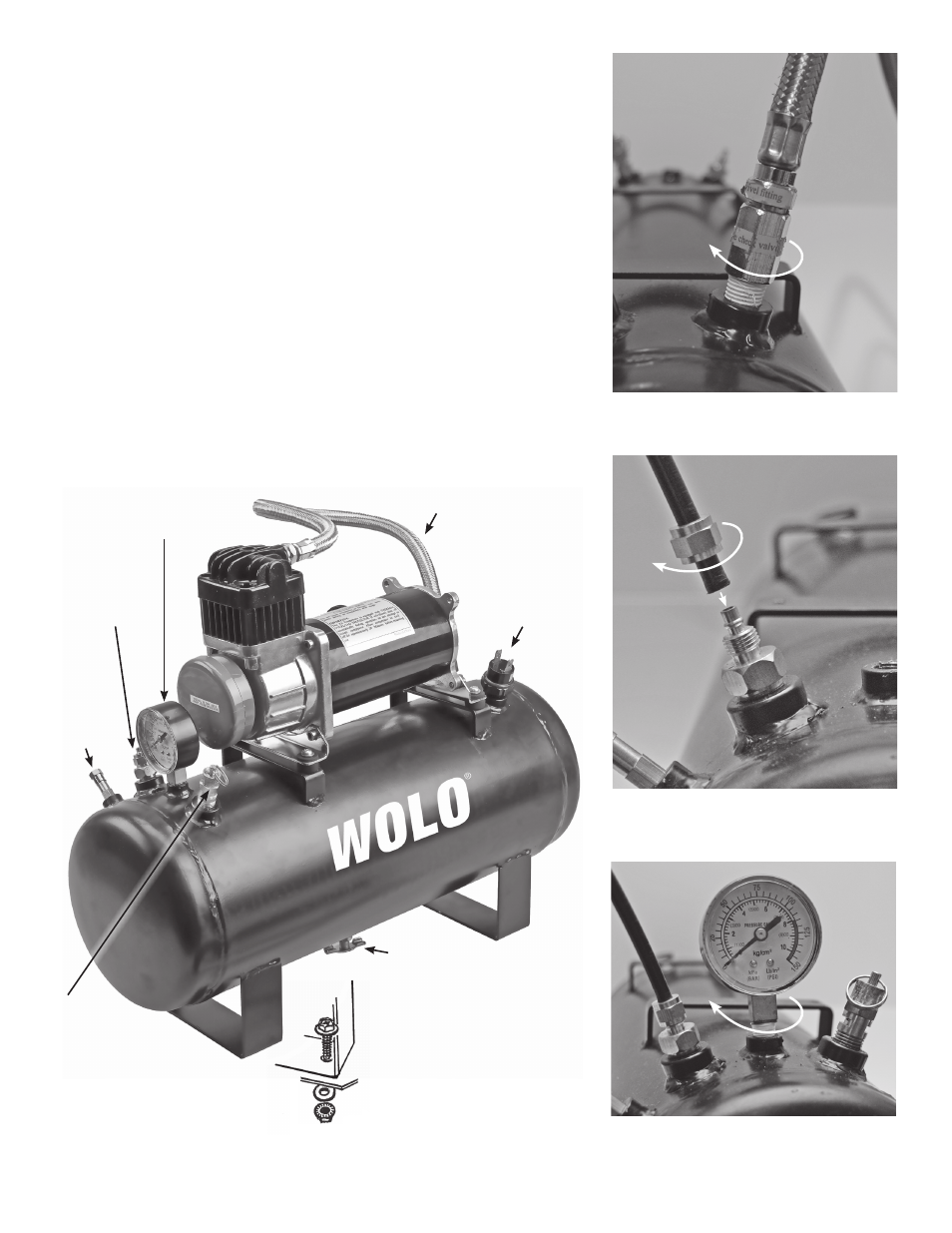

Fig. 3, Fig. 4, Fig. 5 – Wolo 860 AIR RAGE User Manual

Page 2

HOSE INSTALLATION (Fig. 3 and Fig. 4):

6. If the compressor was separated from the tank, connect the

stainless steel braided hose from the compressor to tanks inlet

port. (Fig. 3.) IMPORTANT: Make sure the threaded fitting

on the end of the braided hose has either been wrapped with

Teflon

®

tape or coated with pipe sealant to prevent air leaks.

7. Using the high-pressure plastic hose provided, cut to size to

be able to connect the tank to inlet fitting of the accessory or

valve requiring high-pressure air. Place the brass nut from the

tank’s outlet fitting onto the high-pressure plastic hose. Push

the plastic hose fully onto the outlet fitting, tighten the brass nut

onto the outlet fitting. (Fig. 4.).

CAUTION: Do not over tighten the brass nut.

8. The other end of the plastic hose is connected to the accessory

or valve requiring high-pressure air.

PRESSURE GAUGE INSTALLATION (FIG. 5)

9. Install the pressure gauge to tank. IMPORTANT: The threads of

the gauge have been wrapped with Teflon

®

tape to prevent air

leaks, do not remove the tape. CAUTION: Do not over tighten

the gauge when installing.

Fig. 3

Connecting the metal braided hose

Fig. 4

Connecting the high-pressure

plastic hose

Fig. 5

Connecting the pressure gauge

Shown above: Compressor mounted on the tank

Turn

clockwise

Turn

clockwise

Turn brass nut

clockwise

Petcock

should be easily

reachable so that

the tank can be

periodically serviced

Pressure

Switch

High-pressure

tank outlet

Pressure

Gauge

Schrader

Valve-

to connect

to 20’

coiled

hose

Braided

hose

Use the tank’s mounting base

as a template to mark the

15/32” holes for drilling

Pressure

relief

valve