Thrush PC2G User Manual

Page 2

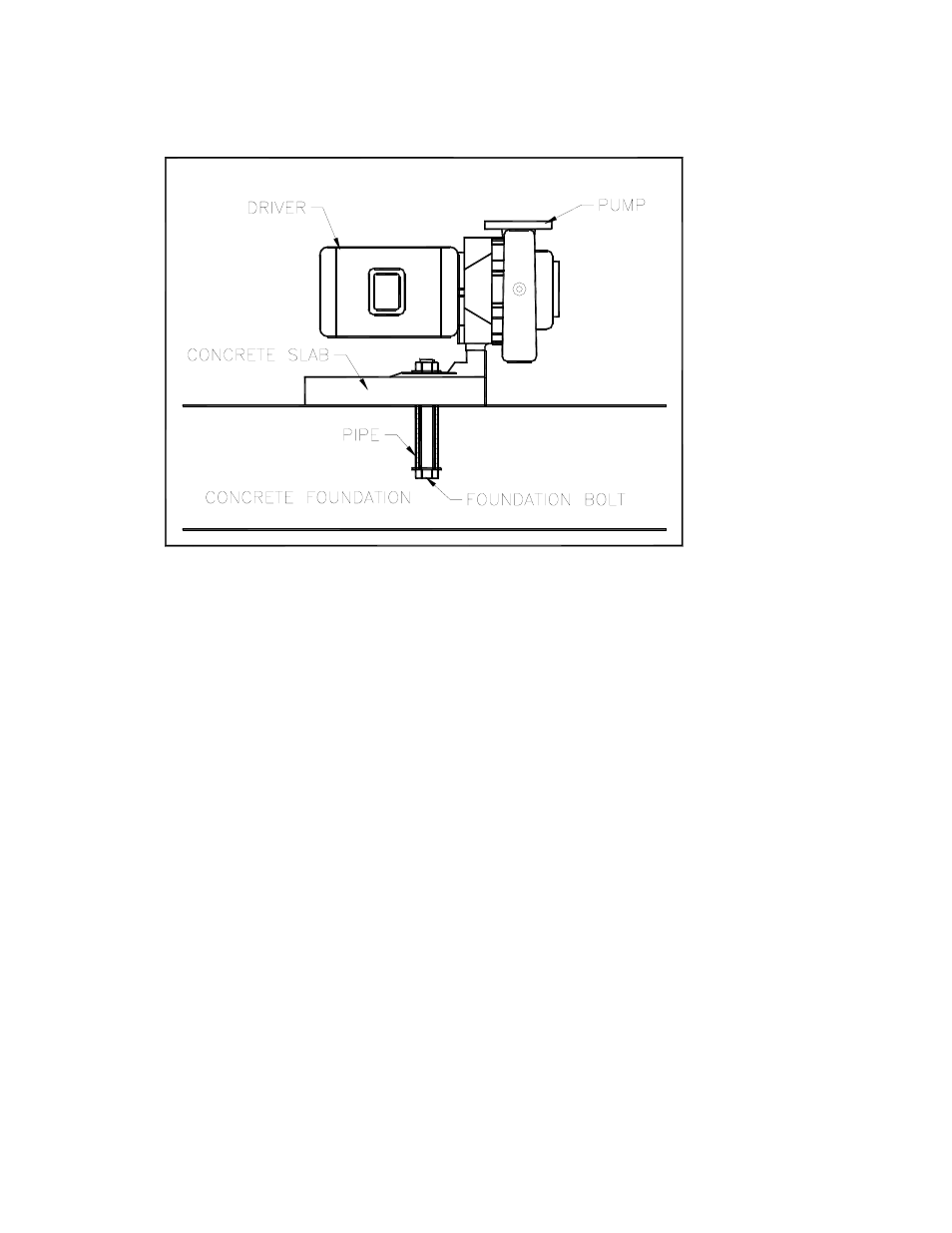

Figure 1

MOUNTING

The pump unit should be set on the foundation, being careful not to damage the threads on the

foundation bolts. The flexible coupling halves should be disconnected. Shims should be inserted

and the pump leveled. A spirit level should be used on the faces of the flexible coupling halves

and on the suction and discharge flanges. If the pump has threaded nozzles, a short piece of

pipe inserted in the nozzles will serve as a smooth surface for a leveling reference point. The

shims should be adjusted until the pump is leveled horizontally and vertically. Tighten the

foundation bolts finger tight.

GROUTING, IF BASE PLATE IS USED

Grouting the base plate prevents lateral movement of the base plate and improves the vibration

absorbing characteristics of the foundation by increasing its mass. A wooden dam should be

constructed around the base plate to contain the grout while it is being poured. The entire base

plate should be filled with grout. Allow 48 to 72 hours for grout to dry. After grout is thoroughly

dried, firmly tighten foundation bolts.

PIPING

The piping practices you follow will directly affect the efficiency and power consumption of your

pump. Pay particular attention to the seemingly insignificant details involved in piping for they

make the difference between a good and bad installation. BOTH THE SUCTION AND THE

DISCHARGE PIPING SHOULD BE INDEPENDENTLY SUPPORTED NEAR THE PUMP;

LIBERAL USE OF PIPE HANGERS AND SUPPORT BLOCKS WILL PREVENT EXCESSIVE

STRAIN ON THE PUMP CASING AND THE PIPE JOINTS. The suction diameter should be at

least the same diameter as the suction nozzle on the pump and preferably larger. Use of a

smaller diameter pipe will result in loss of head due to friction. All joints must be tight to maintain

prime on the pump.