Installation, Gas connection, High elevation – Regency Ultimate U39 Medium Gas Stove User Manual

Page 25

Regency

®

U39 ULTIMATE Direct Vent Freestanding Gas Stove

25

INSTALLATION

U39-NG1: For 0 to 2000 feet altitude

U39-LP1: For 0 to 4500 feet altitude

Burner Inlet Orifi ce Sizes:

Natural Gas Propane

Burner

#32

#50

Max. Input - Natural Gas/Propane

38,000

Btu/h

Min. Input - Natural Gas/Propane

20,000

Btu/h

Supply Pressure

Natural Gas

min. 5" w.c.

Propane

min. 12" w.c.

Manifold Pressure

Natural Gas

3.8"

+/- 0.2" w.c.

Propane

11"

+/- 0.2" w.c.

Electrical: 120 V. 1.13A 60Hz.

Circulation: Variable speed fan, 125/75

CFM.

Log Set: Ceramic fi ber, 7 per set.

System Data:

HIGH ELEVATION - U39-NG1

For 2,000 - 4,500 feet altitude

Burner Inlet Orifi ce Sizes:

Natural

Gas Burner

#33

Max. Input Rating 36,100 Btu/h

Min. Input Rating 19,000 Btu/h

System Data

U39 Converted to 30,000 Btu

For 0 to 4500 feet altitude

Burner Inlet Orifi ce Sizes:

Natural Gas

Propane

Burner

#37

#52

Max. Input - Natural Gas/Propane

30,000

Btu/h

Min. Input - Natural Gas/Propane

15,000

Btu/h

Supply Pressure

Natural Gas

min. 5" w.c.

Propane

min. 12" w.c.

Manifold Pressure

Natural Gas

3.8" +/- 0.2" w.c.

Propane

11" +/- 0.2" w.c.

Electrical: 120 V. 1.13A 60Hz.

Circulation: Variable speed fan, 125/75 CFM.

Log Set: Ceramic fi ber, 7 per set.

System Data

U39 with 40,000 BTU

GAS CONNECTION

The gas connection is a 3/8" NPT 90

o

elbow.

The gas line can be rigid pipe or to make

installation easier, use a listed fl exible connector

and/or copper tubing if allowed by local codes.

Since some municipalities have additional local

codes it is always best to consult with your local

authorities and the CAN/CGA B149 installation

codes.

For USA installations follow local codes and/or

the current National Fuel Gas Code, ANSI

Z223.1.

When using copper or fl ex connectors use only

approved fi ttings. Always provide a union so that

gas lines can be easily disconnected for burner

and/or valve servicing. Flare nuts for copper lines

and fl ex connectors are usually considered to

meet this requirement.

Important: Always check for gas leaks with a

soap and water solution or gas leak detector.

Do not use open fl ame for leak testing.

Note: Prior to any pressure testing of the gas

supply piping system that exceeds

test pressures of 1/2 psig, this

appliance must be disconnected from

the piping system. If test pressures

equal to or less than 1/2 psig are used

then this appliance must be isolated

from the piping system by closing

its individual manual shut-off valve

during the testing.

HIGH ELEVATION

This unit (at 38,000 Btu/h) is approved in Canada

for altitude 2000 ft. to 4500 ft. (CAN/CGA-2.17-

M91) with the orifi ce kit Part # 621-975. For

Natural Gas installations above 4500 ft. follow

current CAN/CGA-B149.1.

In U.S.A., for installations above 2000 ft. refer

to current ANSI Z223.1 Sc8-8.1.2a appendix F,

for resizing orifi ce.

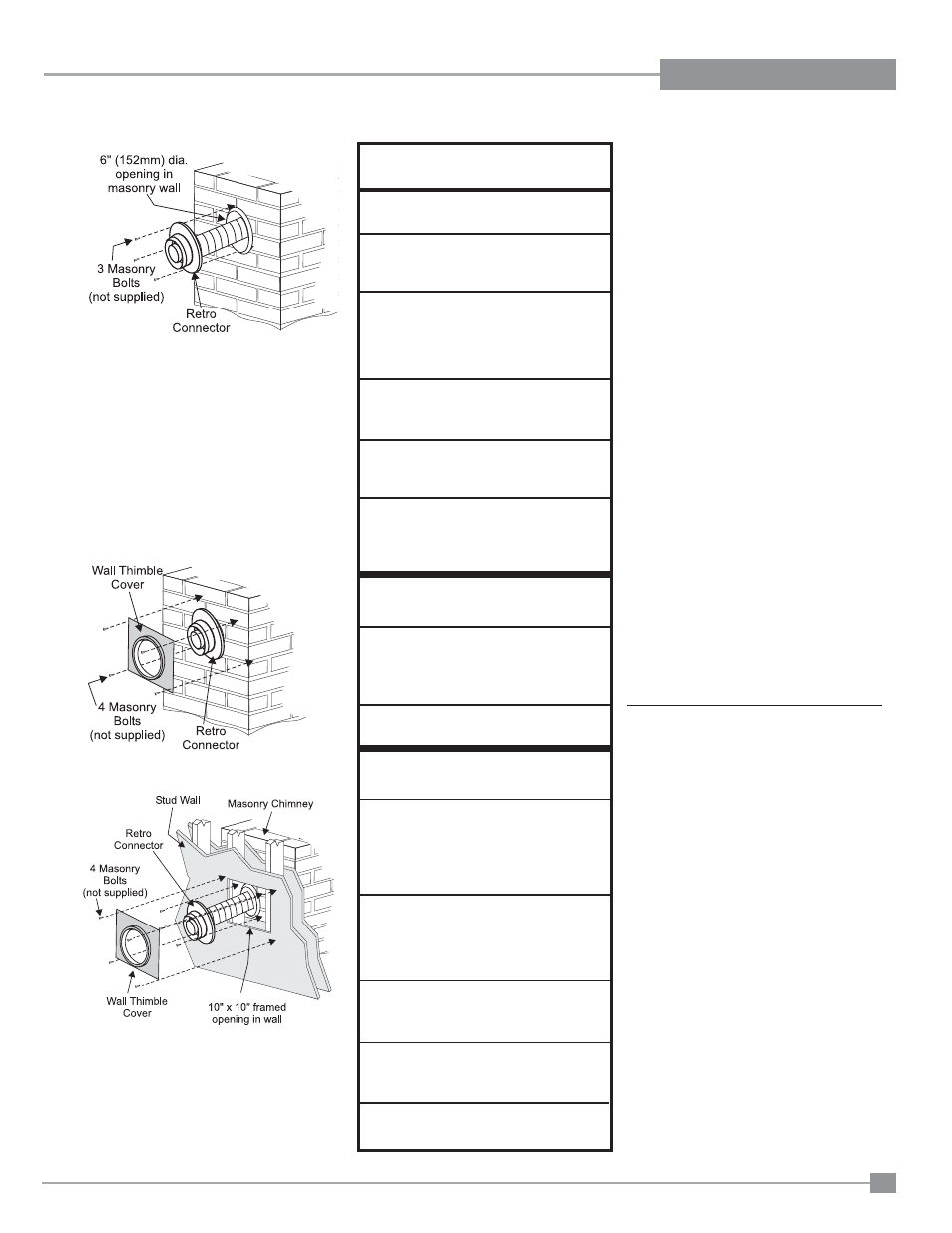

Diagram 9

9) Slide the Wall Thimble Cover over the Retro

Connector and secure with masonry bolts.

Diagram 10. If you have a framed wall in

front of the masonry, use wood screws to

mount the Wall Thimble Cover to the framed

wall, over the Retro Connector and the 10"

(254mm) square framed opening. Diagram

11. If needed, add a section of direct vent

pipe to the Retro Connector in order to extend

through the opening in the Wall Thimble

Cover.

10) The connection between the appliance and

Diagram 10

Diagram 11

the Retro Connector may be completed with

a section of black direct vent pipe, together

with an adjustable length pipe section.