Bunn espress® model es•1af, Site requirements, Physical – Bunn ESPRESS ES.1AF User Manual

Page 4: Adjustable legs, Plumbing, Electrical, Frother disconnect assembly

BUNN

Espress®

Model

ES•1AF

4

SITE REQUIREMENTS

PHYSICAL

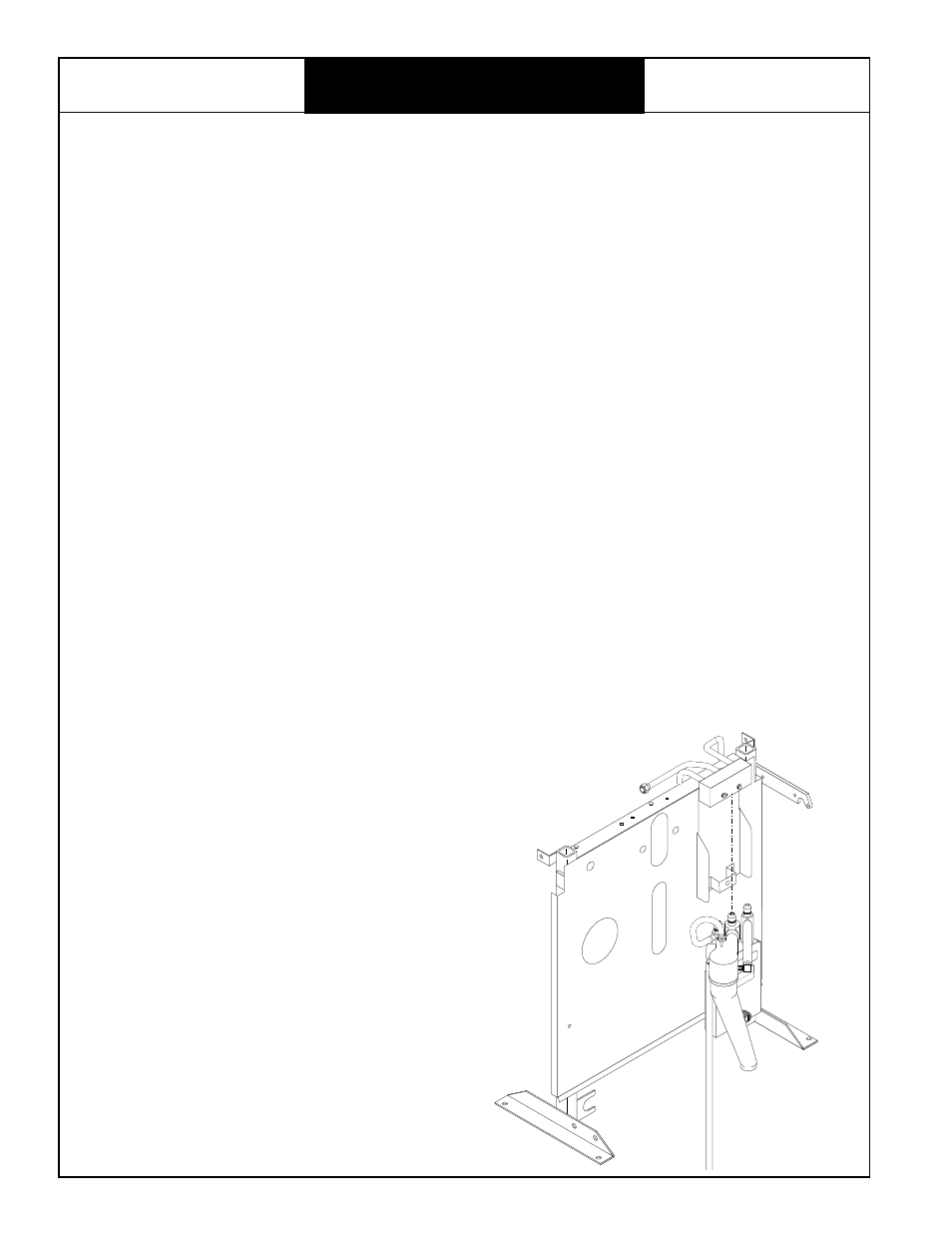

The brewer is for indoor use only on a sturdy counter or cart. It is 16” (40.5 cm) wide, 20” (50.8 cm) tall and

19.25” (48.9 cm) deep. The brewer weighs approximately 88 pounds (40 kg) with the water tank filled.

ADJUSTABLE LEGS

Remove the four rubber feet from the brewer and install the four 4” adjustable legs supplied with the brewer.

Place the brewer on a counter or cart having sufficient space for easy access to water, electricity and drainage.

PLUMBING

The brewer must be connected to a cold water source with operating pressure between 20 and 90

psi (1.5-6.5 bar) from a .5” or larger supply line. Install a shutoff valve in the water line before the brewer.

Install a regulator before the brewer when the pressure is greater than 90 psi (6.3 bar) to reduce it to

45-60 psi ( 3-4 bar). The enclosed water strainer, water inlet hose assembly and drain hose must be

installed.

NOTE-Only softened or demineralized water should be used in this espresso brewer to reduce the service

problems caused by naturally occurring elements in your local water supply. A polyphosphate feeder is

not recommended because it does not remove minerals.

NOTE-Bunn-O-Matic recommends .375” copper tubing for no more than 25 feet from the .5” water supply

line. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The size and shape

of the hole made in the supply line by this type of device may restrict water flow.

ELECTRICAL

The brewer is equipped with an attached cordset and requires a 2-wire, grounded mating receptacle

rated 120 volts ac, 20 amp, single phase, 60 hz. An electrician must properly install a NEMA 5-20R

connector to the appropriate electrical service on an individual branch circuit to install this brewer.

CAUTION- The brewer must be properly grounded. A plumbing line will not provide an adequate ground.

FROTHER DISCONNECT ASSEMBLY

When installing frother assembly thoroughly wet O-rings

with water. Using the slide bracket on the front panel as a guide,

slide frother assembly into the frother manifold as far as it will

go. Secure frother assembly with attached thumb screw.

Mu

st w

et o

-rin

g w

ith

cle

an

wa

ter b

efo

re in

CA

UT

IO

N

HOT

Liquid-Steam-Surfaces

P911