Warning, Caution – S&S Cycle Cruise Control Brackets for Super E & G Carburetors User Manual

Page 2

INTRODUCTION

S&S

®

Cruise control brackets for Super E&G Carburetors are

designed for use on big twin & Harley-Davidson

®

Twin Cam 88

®

model engines.

These brackets in conjunction with S&S E&G carburetors will

work with factory cruise control systems on Harley-Davidson

®

motorcycles.

THIS INSTRUCTION SHEET SHOULD BE USED IN

CONJUNCTION WITH S&S SUPER E&G CARBURETOR

INSTRUCTION SHEET 51-1012.

Throttle Cable Requirements

These brackets are designed to use stock Throttle Cables from

1993 up Harley-Davidson

®

motorcycles.

Gasoline is extremely flammable, explosive under certain

conditions, and the fumes toxic when inhaled. Disconnect

battery ground cable before installation to prevent sparks, do

not smoke around gasoline, and perform installation in well

ventilated area away from sparks or open flame.

If motorcycle has been running, wait until engine and exhaust

have cooled to avoid getting burned during installation.

A. Remove the seat and disconnect the battery. See Harley-

Davidson

®

service manual for proper procedure.

B. Remove fuel tank from motorcycle. See Harley-Davidson

®

service manual for proper procedure.

C. Remove carburetor from motorcycle. Refer to carburetor

instruction sheet 51-1012.

1. Once carburetor is removed and drained of all fuel,

remove the top cable guide assembly.

2. Using a small screw driver adjust idle speed screw out

until it is just touching throttle spool stop with the

throttle plate closed. See Picture 1.

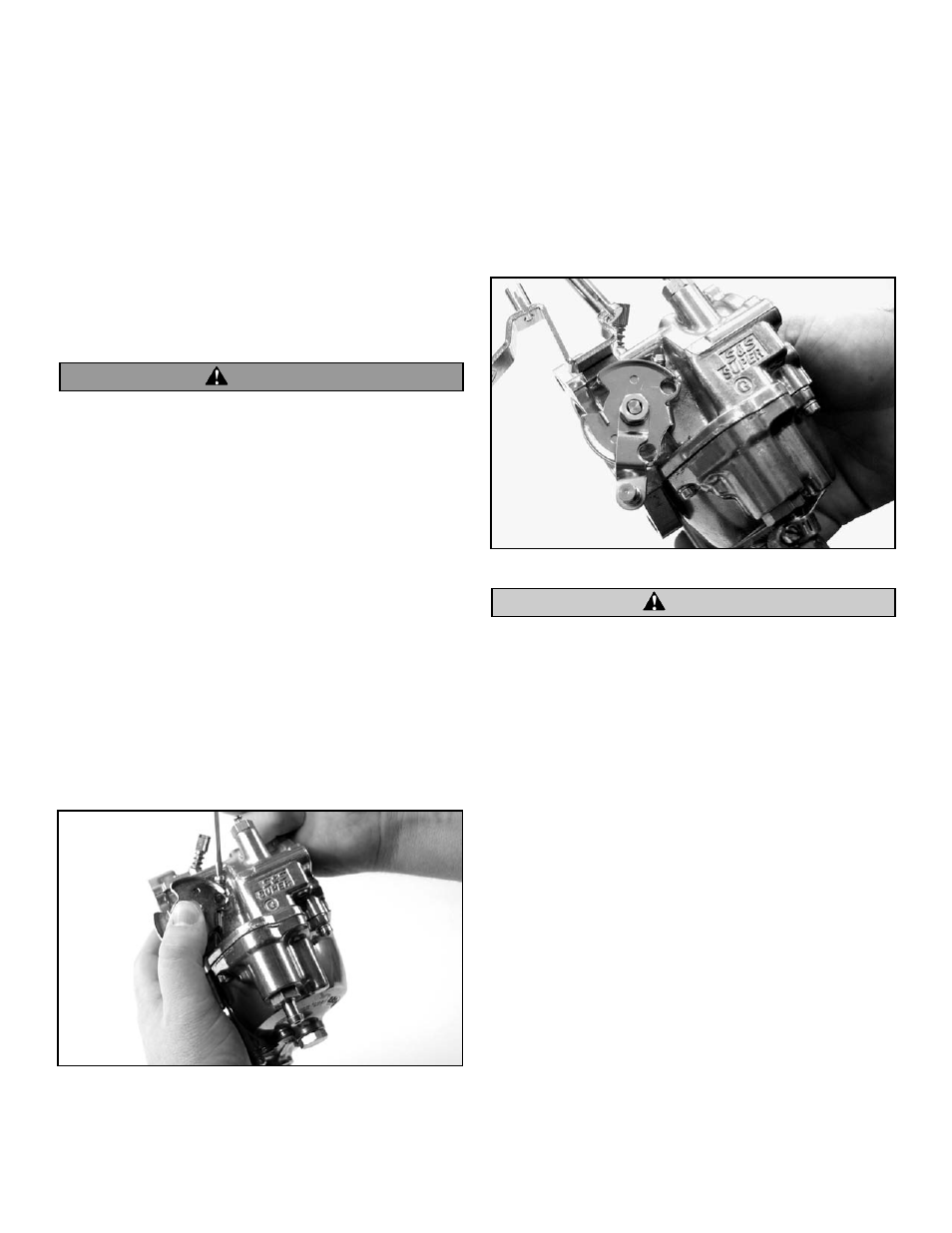

3. Holding the carburetor firmly, remove throttle shaft

nut and lock washer on throttle spool side of

carburetor. Making sure the spool and return spring

don’t come off the shaft. Install new cruise control

arm

on throttle shaft with eyelet arm facing out.

See Picture 2. Re-install lock washer and new thin

nut 50-5027 supplied in kit. (Do not torque nut yet.)

Adjust idle speed screw so it allows throttle plate to

fully close in the carburetor bore. Carefully loosen

(DO NOT REMOVE.) throttle plate screws. Once

screws are loose, torque nut to 40 in-lbs.

Over tightening throttle shaft nut can cause irreversible

damage to throttle shaft and nut.

NOTE: When you torque the throttle shaft nut the throttle plate

will open, let it open until it hits the throttle stop on the

carburetor body. make sure you don’t let it snap shut, let it close

slowly so you don’t damage the bore of the carb body with the

loose throttle plate.

4. Re-center the throttle plate in the bore of the

carburetor. carefully move throttle plate so it centers in

the bore of the carburetor body. (With the throttle

closed you shouldn’t see any gaps where the throttle

plate and bore meet.) Once it is centered, remove one

screw at a time and apply a very small drop of Loctite

®

242 or equivalent to threads and tighten screws. Once

screws are tightened, check to make sure throttle opens

and closes without binding. Throttle should snap shut. If

it binds repeat this step.

5. Readjust idle speed screw . Turn screw counter clockwise

until it no longer contacts throttle linkage spool. Next

turn screw clockwise until it just contacts spool. Then

turn additional 1⁄2 turn clockwise to slightly open

throttle plate.

2

WARNING

Picture 1

Picture 2

CAUTION