S&S Cycle Super D Gasoline Carburetor User Manual

Page 5

5

NOTE: S&S

®

has a special main jet tool, PN 53-0452, which is

perfect for this operation.

DRAGSTRIP PROCEDURE

1. Warm up engine enough to make a pass.

2.

Make a run noting engine rpm and top speed.

3. Richen main jet size .004 larger and make a second run.

Again, note rpm and final speed.

4. Continue procedure until top speed starts to fall.

5.

Lean main jet size by .002 to gain the best performance

from the last pass. When you are making runs, do not be

concerned with elapsed time, rather with consistent

miles per hour.

STREET PROCEDURE

S&S uses what we call the RPMing method to determine your

correct main jet size on the street. By performing hard

acceleration tests, noting rpm at which power starts to fall off

and a gear change is necessary, you will determine what jet

offers the best performance.

1. Warm engine to operating temperature.

2. Accelerate rapidly through the gears noting how

quickly--and smoothly—your engine reaches an rpm

level where power starts to fall off and a gear change

becomes necessary.

3. If the engine backfires in carburetor, breaks up or dies

during acceleration, richen the main jet size .004 larger

and road test it again.

4.

If engine runs sluggish or will not take throttle, lean

the main jet size by .004 smaller and road test again.

Note your engine’s smoothness and how easily it

accelerates to shift points.

5. Determine the best jet size by matching up acceleration

feel to an rpm level that continues to produce power

as you change into the next gear.

ADJUSTABLE AIR BLEED

The main air bleed passage in an S&S Super D carburetor is

equipped with a .040" jet. By allowing the jet size to be

changed you can fine tune the transition from intermediate

circuit to the main jet to match your motorcycle.

Changing the air bleed jet should only be done after you are

absolutely sure that you cannot tune a rideability problem out

by changing the intermediate and main jets. Shifting the start

of the main jet’s operation higher up the rpm scale can lessen

the effects of mid-range problems created by mismatched cam

and pipe combinations. See Photo 6.

JETTING SIZES

NOTES: General Information

1.

Carburetor body has seven drilled passages that are

permanently sealed with drive plugs. Do not attempt to

remove these plugs as irreversible damage to carburetor

may result.

2.

If the throttle arm is removed from it’s shaft, it must be

reinstalled in wide open position with throttle plate at 90˚

to the fully closed position.

3.

The throttle plate should be checked annually for signs of

wear. Replace if necessary.

4.

To insure proper seal in needle and seat assembly, float

hinge, needle lift and needle must work freely and must

not bind. If problem is suspected, remove bowl and check

float movement. If obvious misalignment, binding or

sticking occurs, remove and straighten and reinstall to

attain free movement. Reset float level and double check

for free movement. Float must not contact bowl gasket.

5.

Normal float setting is

1

⁄

32

" and should be measured at end

of float opposite needle and seat assembly. To check this

measurement, turn bowl upside down and measure from

bowl gasket surface up to float.

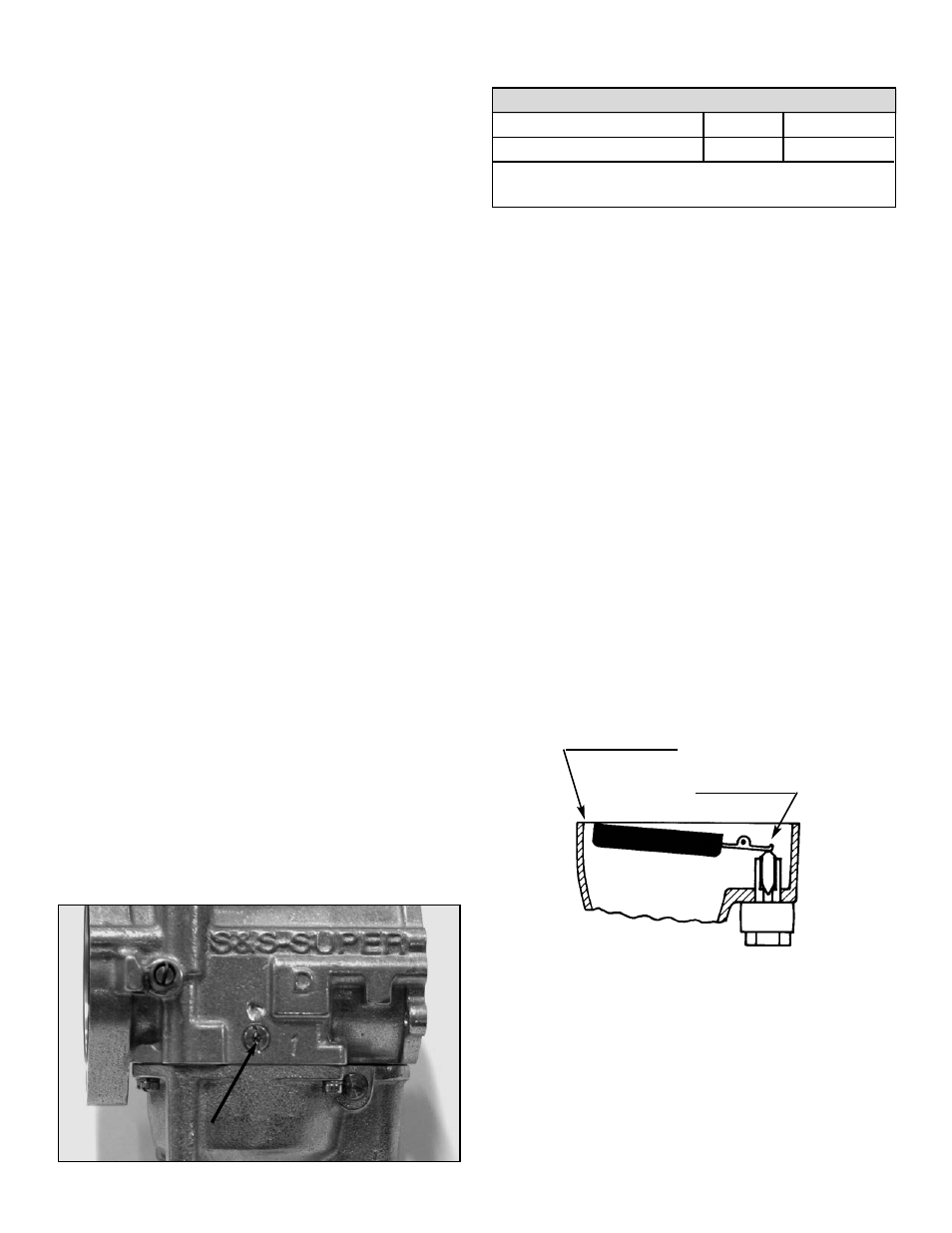

6.

On rubber mounted engines, set float where it just misses

bowl gasket, S&S PN 11-2086, when fuel inlet needle is fully

closed and spring in needle is compressed. See Figure 1. To

check, remove bowl and raise float until needle is in closed

position and spring in top of needle is compressed. Highest

part of float should be slightly (approximately

1

⁄

32

") below

bowl gasket surface. Float must not contact bowl gasket.

Photo 6

Typical Jetting

124 SSW + .032 Intermediate

.098 Main .040 Air Bleed

145 SSW+ .032 Intermediate

.102 Main .040 Air Bleed

NOTE: A number of racing combinations have allowed the

use of up to a .120 Air Bleed.

Figure 1

Float just below gasket surface

(approximately 1/32”)

Spring in needle fully

compressed