Caution warning – S&S Cycle Super B Series Carburetor User Manual

Page 8

Main jet size is best determined by testing at drag strip, because

maximum miles per hour and rpm are best indicators of actual

horsepower engine is developing. S&S

®

recommends that high

speed jetting be done at drag strip.

Dragstrip Procedure

1.

Warm up engine enough to begin testing.

2.

Make run noting engine rpm and final speed.

3.

Increase or richen main jet size .004 larger and make second

run. Again, note rpm and final speed.

4.

Continue procedure until mph falls off.

5.

Decrease or lean main jet size by .002 to gain best

(maximum) rpm and mph. When making runs, do not strive

for ET’s but for consistent miles per hour.

Street Procedure

S&S uses what we call “RPMing” method to determine correct

main jet size. Hard acceleration is evaluated up to the rpm where

horsepower peaks and begins to taper off and gear shift occurs.

Main jet that makes engine accelerate strongest or rpm through

gears quickest is correct.

1.

Warm engine to operating temperature.

2.

Accelerate rapidly through gears noting how quickly and

smoothly engine reaches rpm level where pull of engine

begins to fade and gear shift occurs.

3.

If engine backfires in carburetor and sputters or “breaks up”

and/or dies during acceleration, increase or richen main jet

size .004 larger and road test again. Note engine

smoothness and how easily engine reaches rpm level where

gear shift occurs.

4.

If engine runs flat and sluggish or “blubbers” or will not take

throttle, decrease or lean main jet size .004 smaller and road

test again. Note engine smoothness and how easily engine

reaches rpm level where gear shift occurs.

5.

Continue changing main jets until one is selected that makes

engine accelerate or rpm through gears most quickly and

smoothly. Our experience has taught us that a jet about .006

smaller (leaner) than correct one will make engine “break

up” and quit. A jet about .006 larger (richer) will make

engine “blubber” and miss.

Troubleshooting Tips for Intermediate & High Speeds -

Engine will not run at steady speed or rpm:

1.

Restriction in fuel supply system - gas tank vent plugged,

stock gas petcock too small.

2.

Faulty ignition system - fouled plugs, worn points, defective

coil or solid state module, improper ignition timing.

3.

Incorrect intermediate and/or high speed jetting. See

“Adjusting Carb - Intermediate System” and “High Speed

Circuit or Main Jet”.

4.

Foreign material in air and/or gas passageway in carb

causing flow restriction. Clear holes with forced air.

Do not use wires or drills to clear holes. If sizes are altered,

air/fuel ratios of idle and intermediate systems will be

changed resulting in poor performance and irreversible

damage to carburetor body and intermediate jet.

Compressed air and particles dislodged using compressed air

are harmful to eyes and body. Wear protective goggles

when using compressed air and always direct air stream

away from body parts such as hands and eyes and other

people near you.

5.

No air cleaner used or air cleaner used is brand other than

S&S. Some air cleaner designs restrict air flow so that carb

cannot draw air freely as needed. Also, other air cleaners

may obstruct bowl vent hole on inlet end of carb and change

bowl air pressure.

NOTE - Bowl vent hole passageway leads to cavity above fuel in

bowl and is designed to equalize bowl pressure and atmospheric

pressure. If high or low bowl pressure relative to atmospheric

pressure develops, engine may run erratically.

6.

Air horn used without shrouding bowl vent on end of

carburetor body.

NOTE - Bowl vent should be shrouded to insure uniform

atmospheric air pressure between cavity above fuel level in

bowl and area outside carburetor body. If high or low bowl

pressure relative to atmospheric pressure develops, engine may

run erratically.

7.

Valve train defect - bad valves, sticky valves, bad or broken

springs, improper clearances for high lift cam or, defective

camshaft with improper valve timing.

8

CAUTION

WARNING

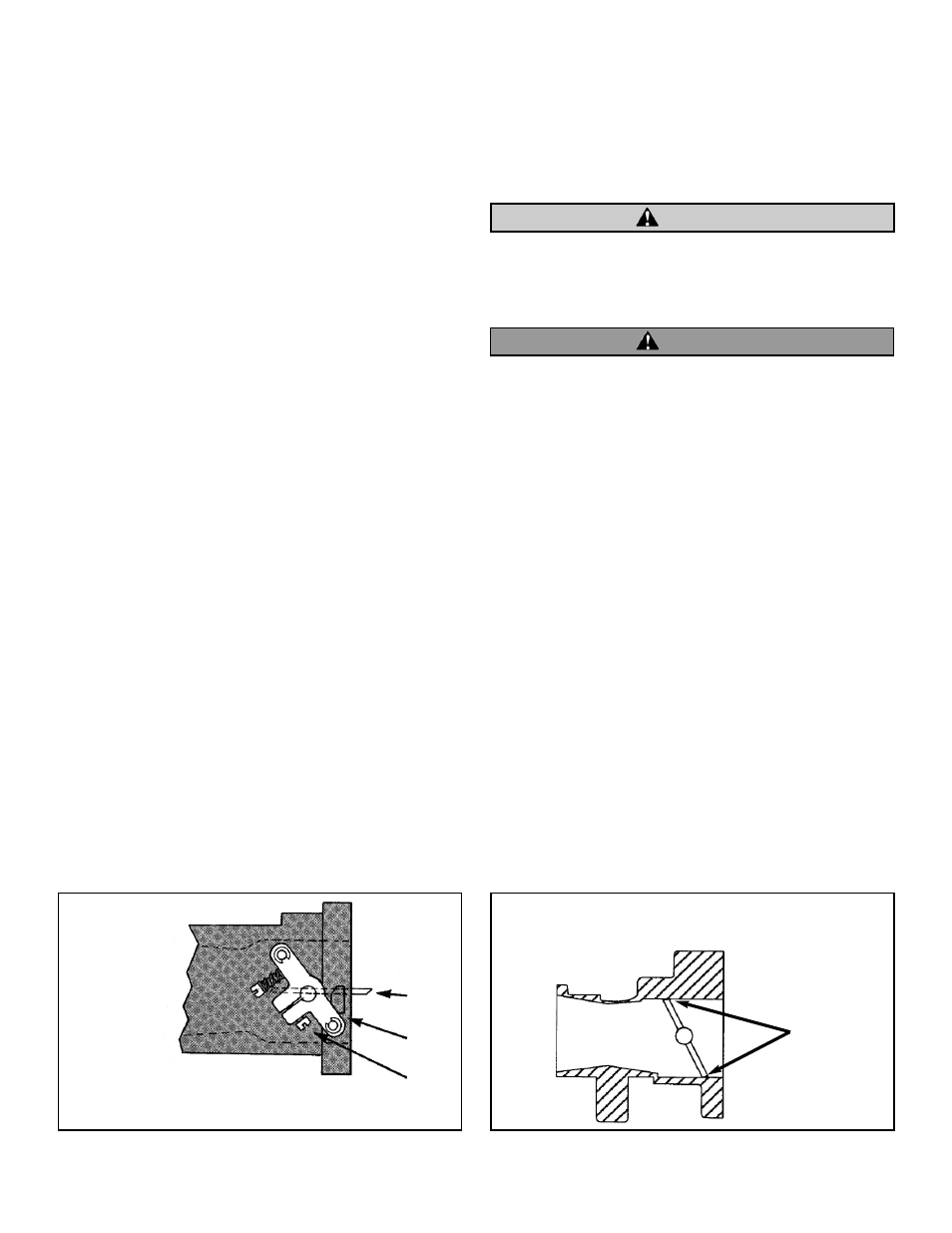

Figure B

Figure C

1

2

3

Arrow 1: Throttle plate horizontal.

Arrow 2: Throttle arm against stop.

Arrow 3: Throttle arm set screw.

Bevels must be at angles shown by arrows

when installing plate.