S&S Cycle TWO THROAT Carburetor (Serial E1190 & Higher) User Manual

Page 8

D. General Information

1.

Do not chrome the carburetor as extensive

damage will result.

2.

The carburetor has several drilled passages that

are permanently sealed with plugs. Do not attempt

to remove these plugs.

3.

Do not over-tighten the idle mixture screw,

intermediate jets, or intermediate air bleeds.

4.

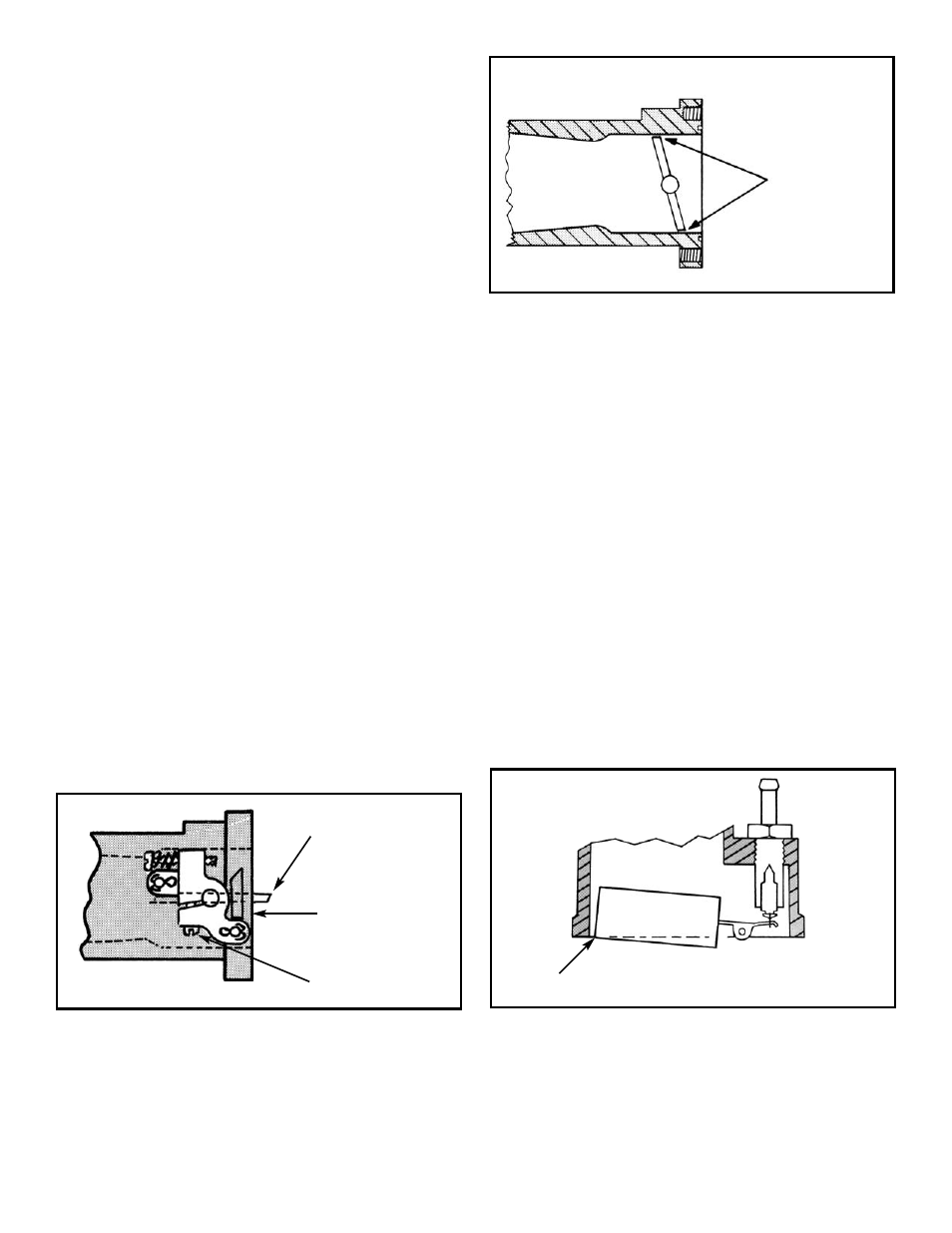

The throttle plates. Part #11-2255, and throttle

shaft, Part #11-2254, should be checked annually

for signs of wear. Replace, if necessary. If they are

removed, be sure that the throttle plates are

reinstalled correctly.

See Figure A.

5.

If the throttle arm, Part #11-2248, is removed from

the throttle shaft, it must be reinstalled in the wide

open position with the butterfly at 90° to the fully

closed position.

See Figure B.

6.

The correct float level adjustment is shown below in

Figure C. When the motorcycle is not running, the

fuel shutoff valve should always be turned of. In the

event fuel runs out of the bowl overflow hose,

remove the bowl assembly and inspect the float and

needle and seat assembly to be sure it doesn’t bind

and the float level is properly set.

See Figure C.

7.

If an air cleaner other than ours must be used,

make sure the bowl vent hole in the inlet end of the

carburetor is not covered and sealed off.

8.

Cams and exhaust systems make some engines

difficult to carburate. A combination of cam overlap

and back pressure, or lack of back pressure will

cause mixture dilution at certain engine RPMs.

This dilution will cause engine roughness or

misfiring when the engine is held in this range. To

attempt to carburate for this condition usually

destroys the carburetion over the rest of the range.

It is best under these conditions to change the cam

and/or the exhaust system.

9.

S&S

®

has found that stock head pipes equipped

with a good quality slip-on muffler will provide a

nice amount of horsepower and torque.

10. Use a fuel filter to keep dirt out of this carburetor.

With the small metering holes used in the

intermediate system and the accelerator pump

nozzles, it is wise to insure against contamination

to provide trouble free operation.

8

Figure A

Top

Side View

Bevels must

be at angles

shown when

installing

throttle plate.

Figure C

Side View

Bowl is shown upside down.

Figure B

Side View

Throttle plate

horizontal

Throttle arm

set screw

Throttle arm

against stop