Warning – S&S Cycle Air Cleaners for Stock Harley-Davidson Carburetors,1994-up Carbureted Buell Models and all 1999-up Single Runner Fuel Injected Models User Manual

Page 5

5

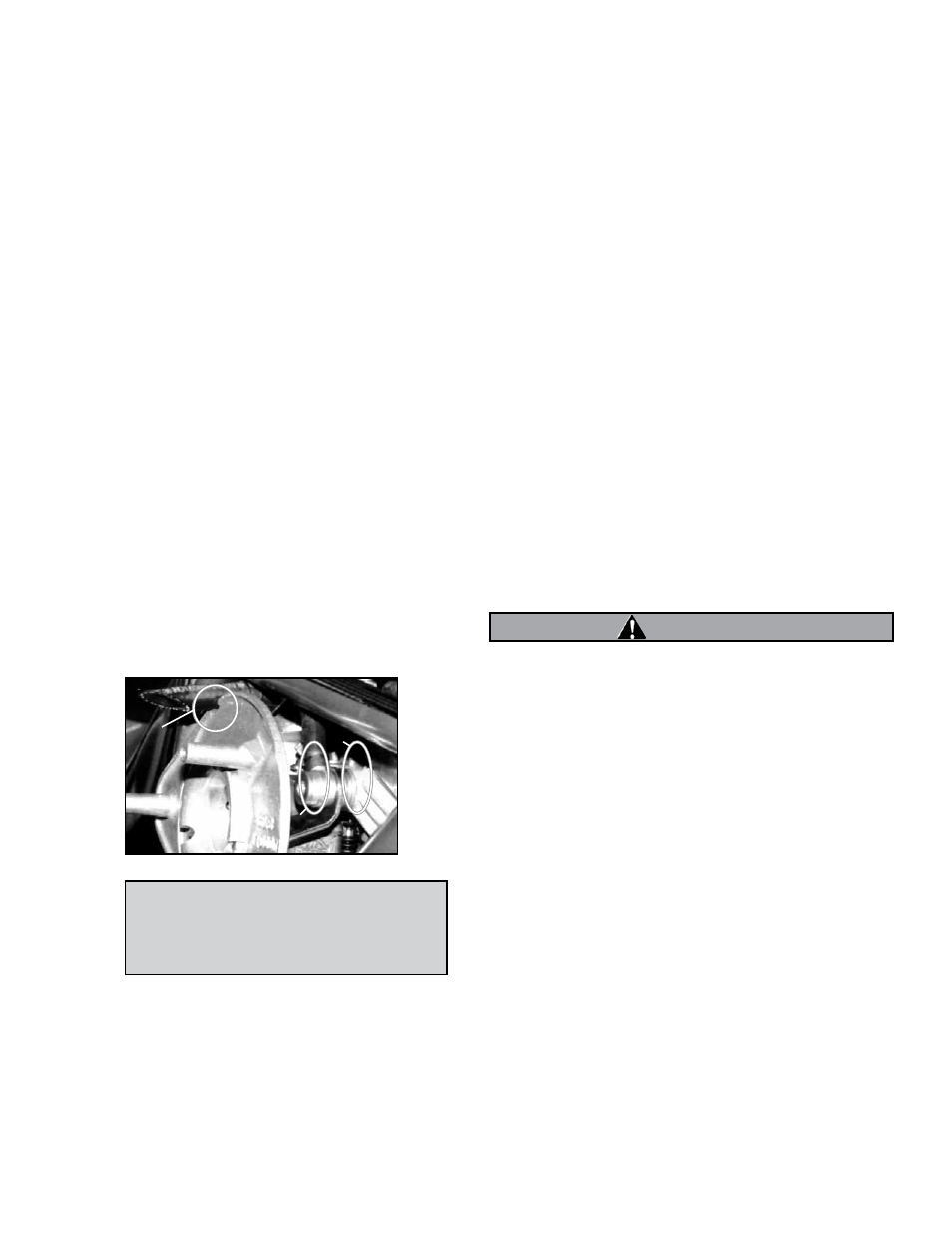

10. Place wire tie or metal clamp over T of T-hose, insert 1⁄2" steel tube

50-8121 part way into T and tighten clamp. Then slide short length

of beveled hose 17-0365 over 1⁄2" steel tube with beveled end out

and facing down. Tighten clamp. See Picture 1.

11. Apply a few drops of Loctite® 242 (blue) or equivalent to threads,

install nuts and lockwashers.

12. Tighten all mounting hardware.

NOTE: Torque specifications: 3⁄4" flat vent fittings 15-20 ft-lb with red Loctite®

(262) Air Cleaner mounting screw 8-12 ft-lb with no Loctite®.

13. Install filter element and air cleaner cover. Secure with three air

cleaner cover screws 50-0072 to complete installation.

14. Start motorcycle, inspect for leaks, and test ride. Engine should run

smoothly after proper warm-up. Surging or misfire may indicate

lean carburetion. If necessary, consult professional mechanic

regarding possible need to install correct carburetor jetting.

INSTALLATION KIT 17-0105 (See line drawing on page 7.)

1.

Remove existing air cleaner assembly and related hardware

including cylinder head breather fittings if applicable. Refer to

authorized Harley-Davidson® Service Manual as needed.

NOTE: Hose barb on rear cylinder head breather fitting must be removed.

To remove fitting from cylinder head, a cut-off wheel or similar tool is used

to cut barb off. Care must be taken that no metal chips get into the breather

fitting. S&S® recommends packing fitting with grease. An alternative is to

grasp barb with pliers and snap off.

2. Place head vent shim 50-7120 over breather cap screw 17-0338

and roll 5⁄8" O.D. O-ring 50-8032 into large diameter O-ring groove

closest to head of breather screw. (See Picture 4 Item A).

3. Roll 1⁄2" O.D. O-ring 50-8006 into small diameter O-ring groove of

breather screws. Apply thin film of light grease to O-rings.

NOTE: Breather fitting O-rings are easily damaged. It is suggested that

replacements be obtained prior to removing breather fittings in

future.

4. Repeat for other breather screw.

5. Pass breather screws through breather fittings 17-0337 and stock

support bracket. Do not tighten at this time.

NOTE: At least one .125" shim must be installed between breather fitting

and cylinder head. Otherwise breather screw may bottom out in cylinder

head, resulting in oil leak and possible damage to head or screw. (See

Picture 4 Item B)

6. Position the included gasket between the backplate and carb. Install

backplate on carb.

NOTE: Backplate screws supplied with this kit have thread locking compond

on threads. If screw without thread locking compound is used, a

thread locking compound such as Loctite® 242 must be applied, and

screws properly tightened.

7. Remove backplate and breather screw assemblies, then install shims

and reinstall breather screw assemblies. Do not tighten at this time.

8. Align breather fitting outlets to permit installation of T-hose.

9. Install rubber T-hose 17-0339 over cylinder head breather fittings

with hose tee toward rear of engine. Hose must not be kinked or

otherwise obstructed, and should be trimmed to length as needed

to align tee with backplate cut out. Once proper fit is obtained,

secure T-hose to breather fittings with black tie-wraps or clamps

provided. (See Picture 4 Item C)

10. Place wire tie or metal clamp over tee of T-hose, insert 1⁄2" steel

tube 50-8121 part way into tee and tighten clamp. Then slide short

length of beveled hose 17-0365 over 1⁄2" steel tube with beveled

end out and facing down, and tighten clamp. (See Picture 1)

11. Apply a few drops of Loctite 242 (blue) or equivalent to threads,

install nuts and lockwashers.

12. Tighten all mounting hardware.

13. Install filter element and air cleaner cover. Secure with three air

cleaner cover screws 50-0072 to complete installation.

Vent hose must not contact hot or moving surfaces that could

damage it and expose brakes or tires to crankcase oil/air mist. Oil

on these components could result in loss of control of motorcycle

with death or severe injury to operator and others.

14. Start motorcycle, inspect for leaks, and test ride. Engine should run

smoothly after proper warm-up. Surging or misfire may indicate

lean carburetion. If necessary, consult professional mechanic

regarding possible need to install correct carburetor jetting.

Picture 4

A-50-7120 spacer.

B-.125" spacer required (minimum).

C-Vent hose in notch in backplate.

WARNING

A

C

B