S&S Cycle EFI Stock Crank Position Sensor 1995 1/2 - 1998 User Manual

Page 2

2

Removal of Crank Position Sensor Hole Cover Plate and Plug

The engine is shipped with a crank position sensor hole plug to prevent leakage of fluids during shipping. This plug must be removed to allow

installation of the stock crank sensor.

1- Remove two Torx® #8-32 x 3/8” screws used to fasten cover plate. These screws can be used later to install the crank position sensor.

2- Insert a ¼-20 bolt into the crank position sensor plug.

3- Use a pair of pliers to grip the ¼-20 bolt and carefully extract the crank position sensor plug from the hole. Pull the plug strait out of the hole

to avoid damaging the crank position sensor hole.

Installation of Stock Crank Position Sensor

IMPORTANT! The crank position sensor mounting block used in stock applications is not used with the S&S engine. If this block is installed, the crank

position sensor will be too far from the flywheel. This could cause the fuel injection system to operate improperly or not at all.

1- Slide the stock O-ring (H-D®# 11170) around the crank position sensor up to the metal mounting bracket. Apply a small bead of high-

temperature gasket material around the outer edge of the O-Ring to ensure a leak-proof seal.

2- Insert crank position sensor into crank position sensor hole.

3- Apply a small amount of Loctite® 222 to threads of Torx® #8-32 x 3/8” screws and use them to fasten the crank position sensor to the crankcase.

Tighten screws to 17- 21 in-lb.

Upgrading your 19951/2 - 1998 harness to accept the S&S® (1999-later) crank sensor (55-1051)

Some customers may choose to upgrade their crank position sensor to the one used on several S&S engines. This may be done by following the

procedure below:

Modification of Crank Position Sensor Connector

Parts Needed:

106-0115 Service Kit, Two Position, Deutsch® DTM

•

55-1051 Crank Position Sensor Kit

•

Procedure:

1- Cut the wire for the crank position sensor connector (round 3 position connector) off the motorcycle harness near the connector.

2- Strip the wire shielding off to expose two internal wires.

3- Crimp on terminals and populate the 2 – way connector using the following position assignment:

• 1: Signal, BE

• 2: Signal Return, BK

4- Install locking wedge.

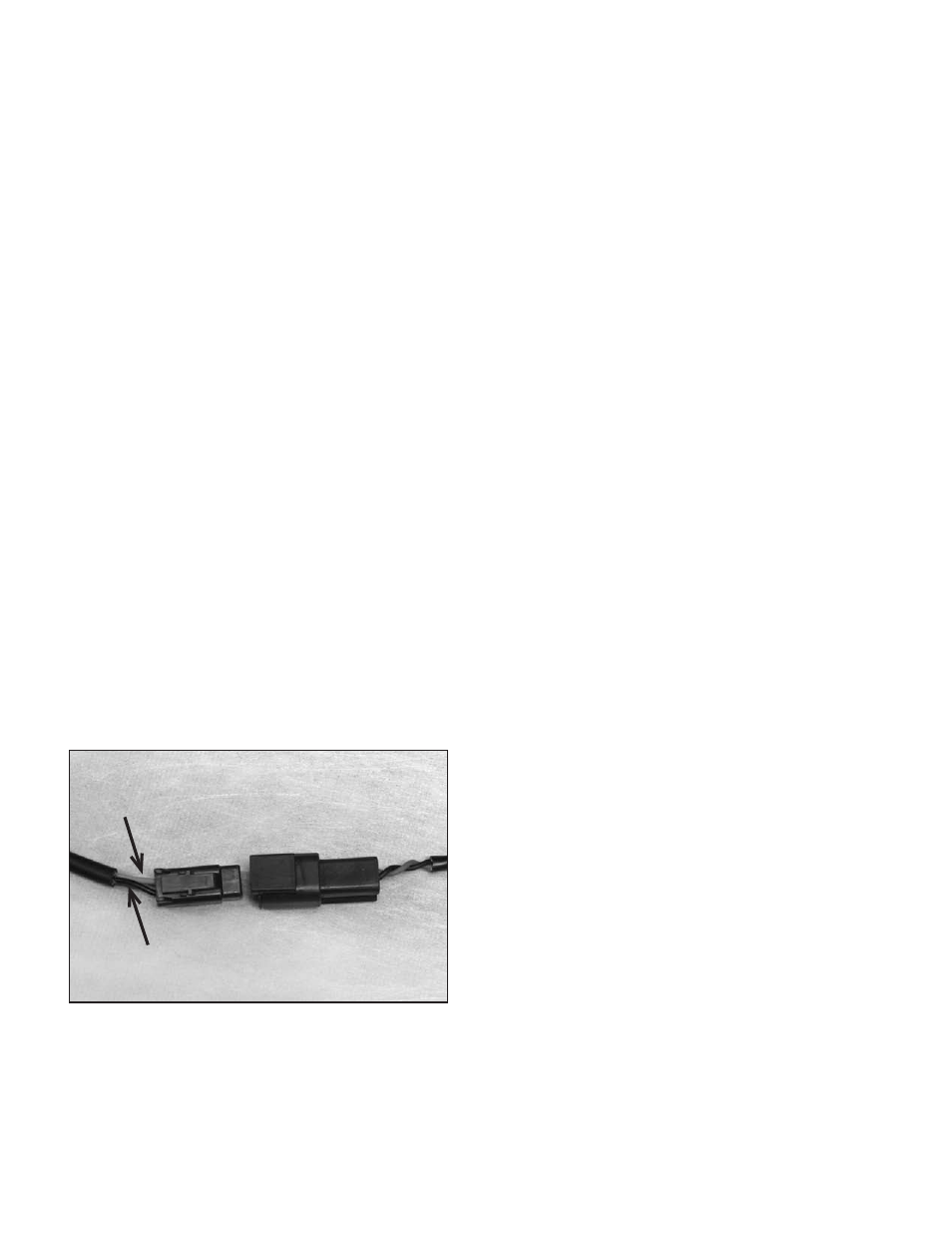

Picture 1

Position 1

Position 2

Installation of the 55-1051 Position Sensor

1- Remove cover plate and plug or stock crank position sensor (if installed).

2- Install the 55-1051 crank position sensor with the included ¼" screw and lockwasher. Torque to 8-10 ft-lb.

3- Connect the harness to the modified motorcycle harness described above.