S&S Cycle Crankcase for Harley-Davidson Twin Cam 88 Engines User Manual

Page 3

Please read these instructions thoroughly before starting work.

Proceed with the installation only after they are completely

understood. These instructions should be supplemented by the

appropriate OEM service manual for your motorcycle. Follow all

safety information.

INTRODUCTION

S&S

®

crankcase assemblies for Harley-Davidson

®

Twin Cam 88

®

non-counterbalanced engine applications. Installation can be

performed by any Harley-Davidson

®

repair shop equipped to do

complete engine overhauls. No special tools other than those

used in normal engine building operations are required.

Stock bore cases are perfect for stock replacement applications,

4" bore cases are a natural for use with the S&S

®

Hot Set Up Kit

®

for Twin Cam 88, and 4

1

⁄

8

bore cases make it possible to build

really large displacement custom engines.

NOTE: S&S crankcases are sold in matched sets only. Individual

case halves are not available.

ADDITONAL OIL LINE INSTALLATION KIT REQUIRED

G Dyna

®

- PN 31-0424

G FL - PN 31-0425

ADDITIONAL FEATURES:

G Greater overall strength than stock crankcases, especially in

the front motor mount, an important consideration in high

performance applications.

G All oil passages between the crankcase and gear cover are

o-ring sealed.

G Compatible with stock components. Use stock oil pump, cam

support plate, gear cover, etc.

G 1999-2002 Timken

®

style sprocket shaft bearing. (Included)

G Uses 2003-up pinion shaft bearing

G Special order crankcases offer your choice of cylinder spigot

bore, cylinder stud pattern, and your choice of rear motor

mount style - 1999-06 or 1984-1999.

KIT CONTENTS

G Crankcase with camshaft bearings and cylinder studs installed

G Sprocket Shaft Bearings

G S&S Reed Valve Assembly

G Pinion Bearing

G Hardware Package

G Certificate of Origin

G Instructions

POLISHING, PAINTING, PLATING, OR POWDERCOATING S&S CASES

S&S Cycle cautions against modifying these crankcases due to the

possibility of damaging or weakening them. Modifying S&S

crankcases in any fashion voids all manufacturer warranties.

Should the customer elect to modify the crankcases regardless, it

is imperative that they and the information tag attached to them

be inspected beforehand to confirm that the correct model, style,

bore size, etc. have been provided. The customer must confirm

that crankcases and related parts are correct before assembling

them or having them modified in any manner, and assumes all

liability for modifications.

The customer must also verify that the serial numbers on the

crankcase and attached information tag correspond with those

on the certificate of origin and packing carton.

Under no circumstance will S&S be held responsible for expenses

related to the modification of any S&S part in the event warranty

service is required. Modified parts will not be accepted for credit

or exchange. This will apply regardless of cause or fault:

customer, retailer, manufacturer, or other.

For further information, contact S&S Technical Services at

608-627-8324, FAX 608-627-1488 or e-mail [email protected]

NOTE: Modification includes but is not limited to appearance

changes such as painting, powdercoating, plating, and polishing.

Proper preparation for these procedures as well as the processes

themselves may require the use of polishing compounds,

chemicals or procedures that are potentially harmful to

crankcases.

Passages and internal cavities may become obstructed by

residues from materials used to polish, paint, plate or

powdercoat surfaces. Additionally, surface finishing processes

can damage critical machined surfaces. Any of the above may

cause premature wear, damage or failure of other engine

components as well as the crankcases themselves.

Powdercoating - Subjecting heat-treated alloys such as those

used in S&S

®

crankcases to excessive heat can drastically alter

their strength and their critical properties. The degree of change

depends upon the temperatures reached and the duration of

exposure. When powder coating or otherwise processing alloy

parts, S&S exposes them to a maximum temperature of 370°F for

no longer than 20 minutes. Under no circumstances should parts

be heated past 400°F!

3

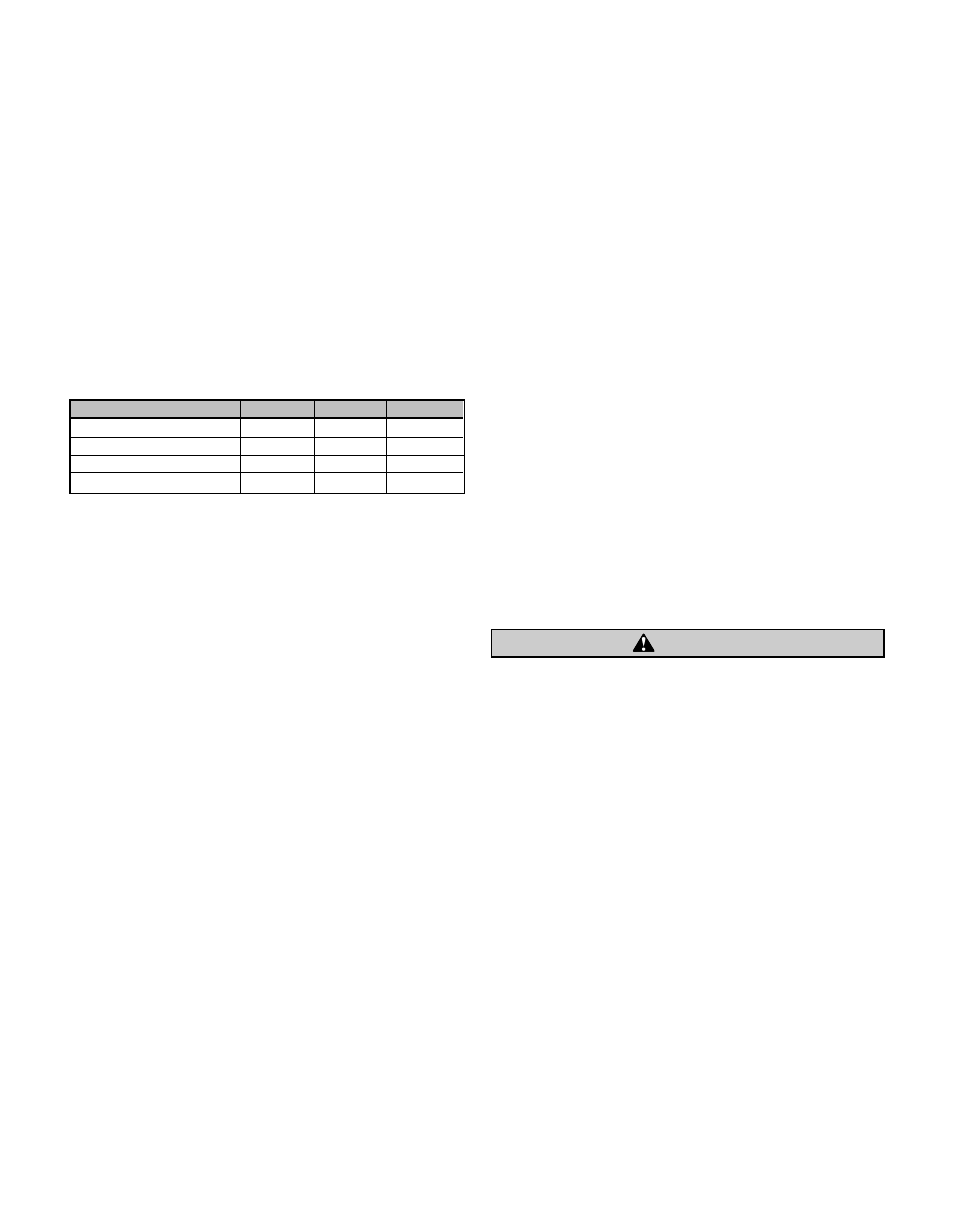

S&S

®

Crankcases for 1999-’06 Big Twin Engines

Bore Size

Silver

Black

Polished

Stock Bore

106-4039

31-0172

N/A

4" Bore

106-4041

31-0175

N/A

4

1

⁄

8

” Bore (

Stock Stud Pattern)

106-4057

31-0181

31-0182

4

1

⁄

8

" Bore

(S&S Stud Pattern)

106-4043

31-0178

31-0179

CAUTION

Crankcase Breather & Oil Pressure Switch Location