Caution – S&S Cycle Big Twin Crankcase Gearcover Kits User Manual

Page 2

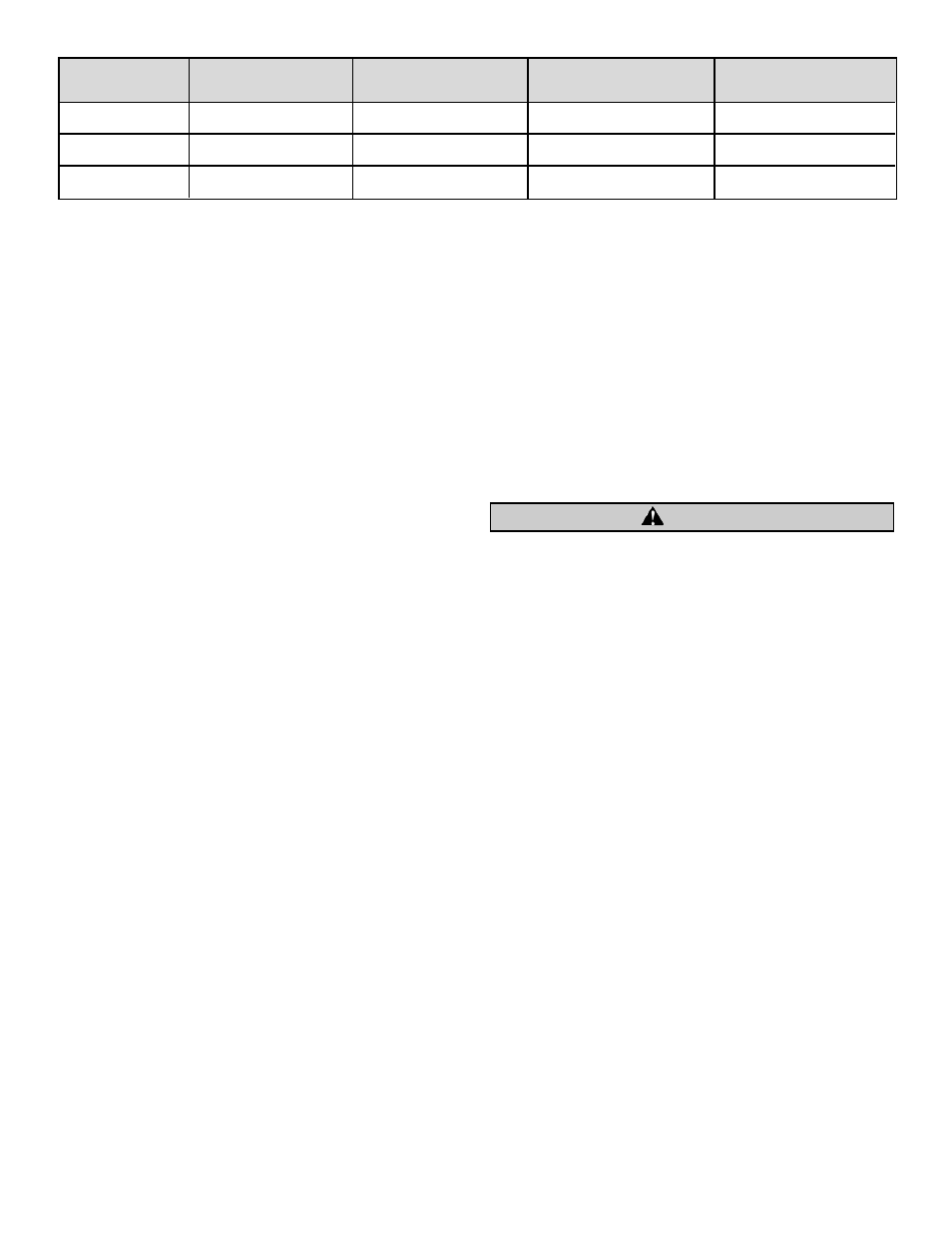

S&S

®

crankcase gearcover kits are available in four styles, and

each style is available for three year groups. (See chart above.)

Because of differences in oiling and scavenging systems, kits for

different year groups are not interchangeable. Correct kit must

be used to insure proper oil circulation. All S&S gearcase covers

may, however, be used with either end-oiling or side-oiling

pinion shafts without modification.

KIT CONTENTS

●

Gearcase cover and gasket

●

Chrome outer cover and gasket

●

Inner and outer timing covers and gasket

●

Mounting hardware

NOTES

●

Camshaft endplay must be checked whenever a different

gearcase cover is installed. A new rear lifter guide gasket

and, in some instances, camshaft thrust washer may be

required to complete this installation.

●

The procedure for installing an S&S gear cover is essentially

the same as stock. If in doubt, consult a professional

mechanic or refer to the appropriate Harley-Davidson

®

Service Manual.

●

It is recommended that S&S bushings and gaskets be used for

rebuilds, although in most instances stock components may

be substituted if necessary.

●

S&S gearcovers are supplied ready to use, with both

bushings machined to stock specifications. No further

machining is required.

INSTALLATION

1. Thoroughly clean engine and surrounding area. Some

motorcycles require that front exhaust pipe and/or right

footboard be removed prior to installation. Harley-

Davidson

®

Evolution

®

engines generally require removal of

rocker covers and rocker arms.

2. Remove all four pushrod cover clips and rotate engine

until rear pushrods are at their lowest point. Remove

rear pushrods, oil pressure sending unit, rear lifter

guide, and lifters.

3. Rotate engine to bring front pushrods to their lowest point.

Loosen adjusters to eliminate pressure on camshaft. If non-

adjustable stock pushrods are used, they should be removed as

directed in Harley-Davidson

®

Service Manual.

4.

Remove ignition cover and ignition components located

inside gearcover. Take care that camshaft and/or breather

gear and thrust washer do not come out with gearcover. If

this occurs, they must be reinstalled according to standard

Harley-Davidson

®

procedure. Insure that marks on breather

valve, camshaft, and pinion gear align correctly.

5.

Clean gearcover gasket surface on crankcase. All traces of

gasket material and oil must be removed.

6.

Clean new cover with warm, soapy water and rinse in clean

water. Paying particular attention to oil passages, dry

thoroughly with compressed air.

7.

Check camshaft endplay as follows:

A. Temporarily install cam, gear cover, and new gasket.

Torque cover mounting bolts to 10-12 ft. lbs.

NOTE: Gearcover should slide over dowel pins, pinion shaft, and

cam with little or no resistance. If gear cover does not slide on

easily, cause of resistance must be determined and corrected.

Under no circumstance should cover be forced into place.

Forcing gear cover on may subject pinion shaft to

unwarranted flexing and side loading which can cause shaft

to fatigue and break during operation.

B. A dial indicator or feeler gauge should be used to

establish endplay according to standard procedure.

Recommended end play is .003” to .015”. A thinner or

thicker camshaft thrustwasher may be installed to

correct endplay.

NOTE: S&S has thrustwashers available in .005” increments from

.050” to .070”. See S&S catalog for parts numbers.

8. Coat both bushings with fresh motor oil and permanently

install gear cover. A small amount of gasket sealer may be

used if desired. Torque cover bolts to 10-12 ft. lbs.

9.

Install front pushrods and pushrod tube assemblies. Adjust

pushrods according to manufacturer’s instructions. Reinstall

pushrod cover clips.

10. Clean rear lifter guide and crankcase gasket surfaces. Install

rear lifter guide, gasket, and lifters.

NOTE: Coating lifter guide bores with assembly lube or

other thick oil will help hold lifters in place as guide

assembly is installed.

11. Rotate engine to place rear lifters at their lowest point.

Install and adjust rear pushrods and pushrod tube assemblies

according to manufacturer’s instructions.

12. Coat threads with thread sealer and install oil pressure

sending unit.

2

Year

Flange Style

Billet

Flangeless Tall

Flangeless Tall

Group

Points/Electronic

Points/Electronic

Points/Electronic

Electronic Only

1970-1972

31-0210

31-0242

31-0202

31-0206

1973-1992

31-0211

31-0209

31-0203

31-0207

1993-Up

31-0212

31-0243

31-0204

31-0208

CAUTION