Caution – S&S Cycle Top Dead Center Locator User Manual

Page 2

INTRODUCTION

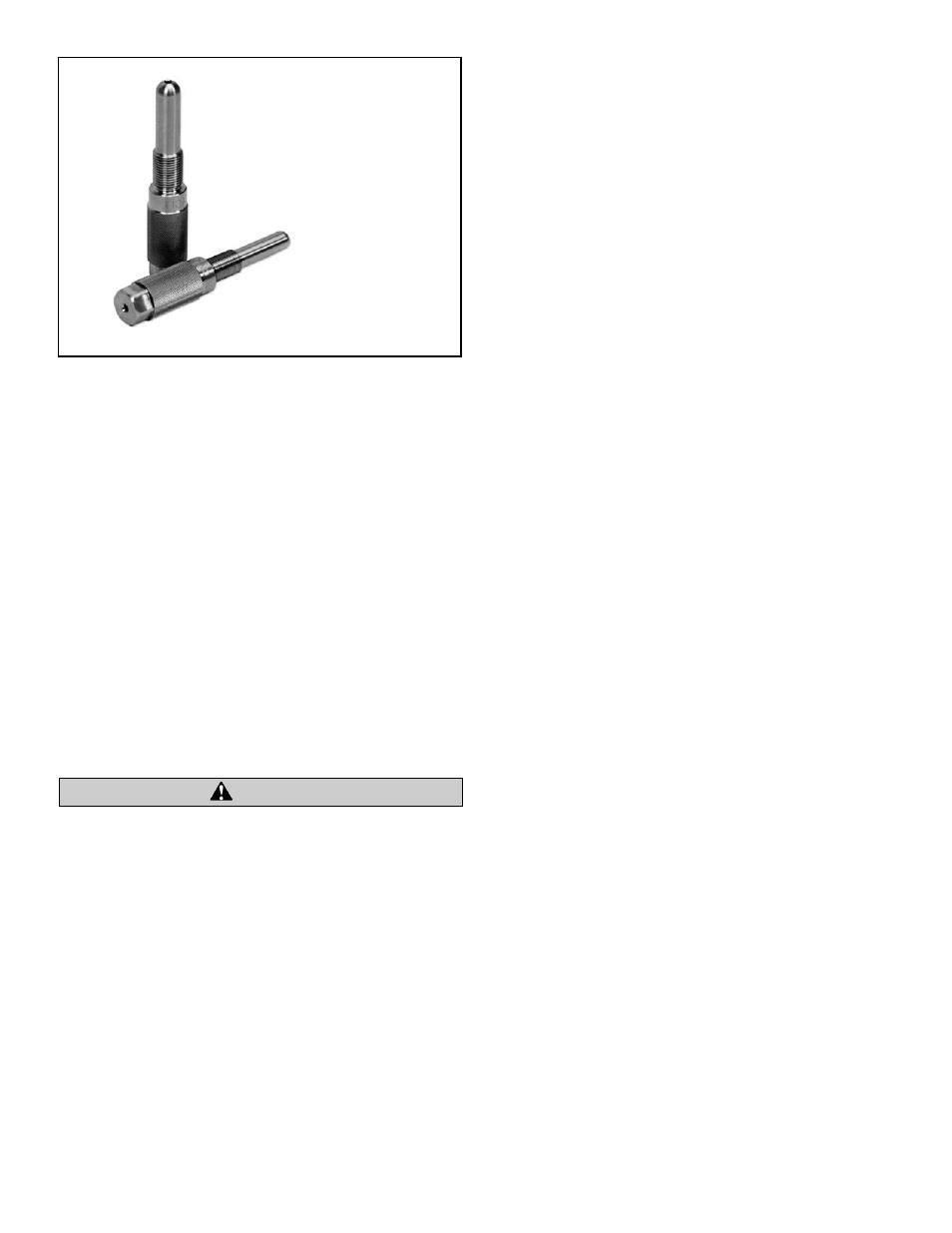

The S&S

®

Top Dead Center Locator screws directly into the spark

plug hole and provides the necessary positive piston stop when

locating top dead center.

Locating exact top dead center is critical when verifying timing

for camshafts intake and exhaust valves and breather gears.

Features include:

●

Made of brass to prevent piston damage.

●

Internal air bleed passage to release compression build up.

●

Knurled grip for easy insertion and removal.

●

Hex head accepts a

5

⁄

8

" wrench.

1.

Attaching a degree wheel (See S&S Instruction 51-1038)

NOTE: The TDC locator should be used in conjunction with a

degree wheel such as S&S PN 53-0020.

If using the TDC locator on a chassis mounted engine, NEVER

use the starter to turn over the engine.

A.

Disconnect the negative battery terminal to prevent

accidental starter operation.

B. Remove front and rear spark plugs (front plug is

removed for TDC locator, rear plug is removed to

relieve compression).

C. Position front cylinder close to top dead center.

D. Attach degree wheel and pointer to engine according

to the degree wheel manufacturers instructions.

2.

Installing the TDC locator

A. Rotate the engine counterclockwise (by hand) to

position the front piston far enough down the bore to

allow installing the TDC locator without contacting the

top of the piston.

NOTES:

●

Whatever wrench or handle is used, it must not change the

position of the degree wheel on the shaft when turning the

engine.

●

A long handle provides better leverage and control than a

short handle.

B. Screw TDC locator into the front spark plug hole until the

base of the knurled area is seated on the cylinder head.

NOTE: Failure to fully seat the locator may allow movement

when the piston contacts the stop which may cause degree

reading errors.

3.

Finding top dead center location

A. Slowly rotate the engine clockwise (by hand) until the

piston contacts the TDC locator.

B. Zero the degree wheel to pointer.

C. Slowly rotate the engine counterclockwise until the

piston contacts the TDC locator again.

D. Note the degree indicated by the pointer.

NOTE: Degrees given in the example below are for illustration

purposes only. Use the values obtained from the steps above

when performing the procedure.

Example: The first contact is at zero degrees (step 2 above) then

after rotating the crankshaft around the other way, the second

contact is at 30 degrees (step 4 above) the total spread between

the two is 30 degrees. (0 + 30) Divide the total degree spread (30

degrees) in half to get the equal number of degrees that the stop

point is on each side of exact TDC in this case, 15 degrees.

E. In the example above, the pointer will still indicate 30

degrees. Without disturbing the position of the piston

against the stop, carefully re-position the degree wheel

so that the pointer indicates 15 degrees.

F.

Rotate engine clockwise to the stop, and back

counterclockwise to the stop, and make adjustments if

necessary so that the degree reading is equal distance

from zero degrees going both directions. When the

degree reading is equal on both sides of zero degrees,

remove the TDC locator. The pointer will now indicate

exact TDC at zero degrees.

G. The engine is now ready for degree checks.

2

Top Dead Center

Locator

CAUTION