Top view driveside camside – S&S Cycle Head Bolts for 1984–12 Harley-Davidson Big Twin & 1986–12 Sportster Models User Manual

Page 3

3

In sufficient thread depth inside head bolt may result in base or head gasket failure and possible engine damage.

3. Before final installation visually inspect studs and bolts, then carefully turn each head bolt down on its respective stud to be sure threads are

clean.

4. Remove head bolts and place a light film of 20W50 motor oil on head bolt threads and contact faces of head bolts and washers. Confirm that

washers are correct for each head bolt according to chart.

NOTE: Proper lubrication minimizes friction to insure accurate torque values.

Incorrect tightening procedure may result in damage to head bolts or cylinder base/head gasket failure.

5. Install head gaskets, cylinders, and head bolts according to manufacturer’s instructions.

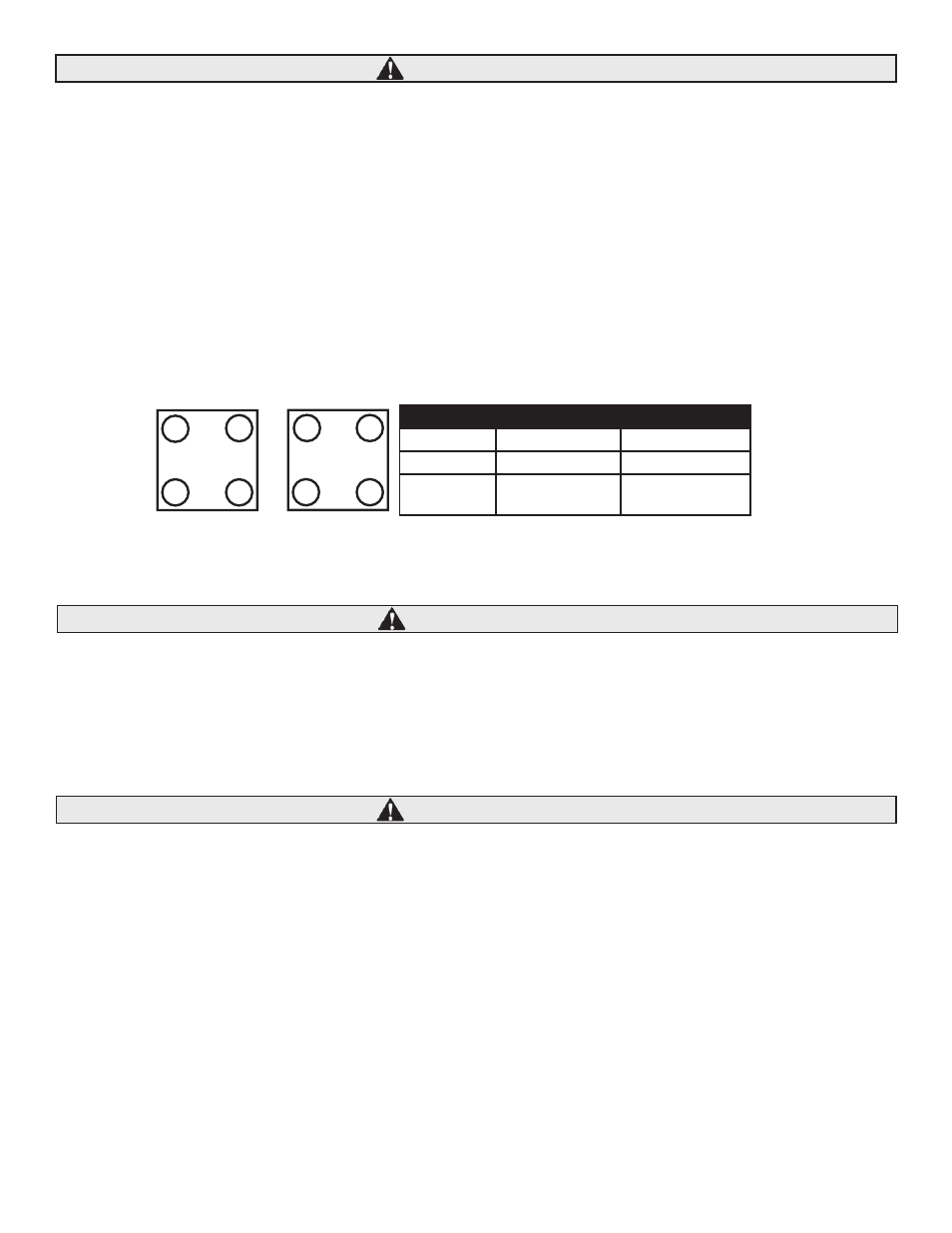

6. If using crankcases other than S&S®, tighten head bolts according to manufacturer’s specifications. If using S&S crankcases, gradually tighten

head bolts according to sequence in Figure 2.

• Incorrect torquing sequence or torque values may damage head bolts or cause cylinder base/head gasket failure.

• Exceeding recommended torque values may pull cylinder studs out of crankcases.

7. Complete top end assembly according to normal procedure. Refer to Harley-Davidson® or S&S service manual as needed.

8. Upon initial start-up, quickly confirm oil pressure and check for gas and oil leaks. With minimal load on engine, ride motorcycle at low speeds

until engine reaches normal operating temperature. Do not crack throttle or subject engine to heavy load during this time.

NOTE: Heat build-up should be gradual for correct gasket seal.

Failure to follow recommended installation and break-in procedures may damage gaskets and other engine parts.

CAUTION

CAUTION

CAUTION

1

2

4

3

2

1

3

4

Top View

Driveside

Camside

Rear Head

Front Head

S&S® Crankcases

Stock Crankcases

Stage 1

8 Ft. Lbs.

7-9 Ft. Lbs.

Stage 2

18 Ft. Lbs.

12-14 Ft. Lbs.

Stage 3

Turn additional 90˚

or 1⁄4 turn

Turn additional 90˚

Figure 2