S&S Cycle Electric Compression Release PN 90-4915 User Manual

Page 2

NOTES

●

S&S

®

compression releases are intended to be installed only

in cylinder heads machined specifically for S&S compression

releases. Stock or other aftermarket cylinder heads may not

have enough material in required areas to allow machining

for S&S compression releases

●

S&S electric compression releases can only be used in

conjunction with S&S die-cast rocker covers or a similar

rocker cover with a center hole or chimney. The chimney

provides clearance for the solenoid which activates the

compression release.

●

Due to the overall length of the compression release

assembly, variations in frames, and the limited space

between the heads and the upper frame tube, it may be

difficult to install the compression releases with the engine

completely assembled in the frame. These instructions are

written assuming there is enough clearance to allow an in-

frame installation, however in some instances it may be

necessary to install the compression releases with the lower

rocker cover in place, or to remove the engine from the

frame. It is suggested that if possible, compression releases

be installed during engine assembly or before heads are

installed on engine.

A.

Installing compression releases

1.

Remove rocker covers.

NOTE: When engine is installed in the frame, there is normally

enough clearance above the heads to install lower rocker covers

with the electric compression releases in place. In some cases,

depending on engine height and frame type, the lower rocker

covers may need to be left on the heads, and compression

releases installed with lower rocker covers in place. In cases of

very limited clearance it may be necessary to remove the engine

from the frame, and reinstall the engine after the compression

releases are installed.

2.

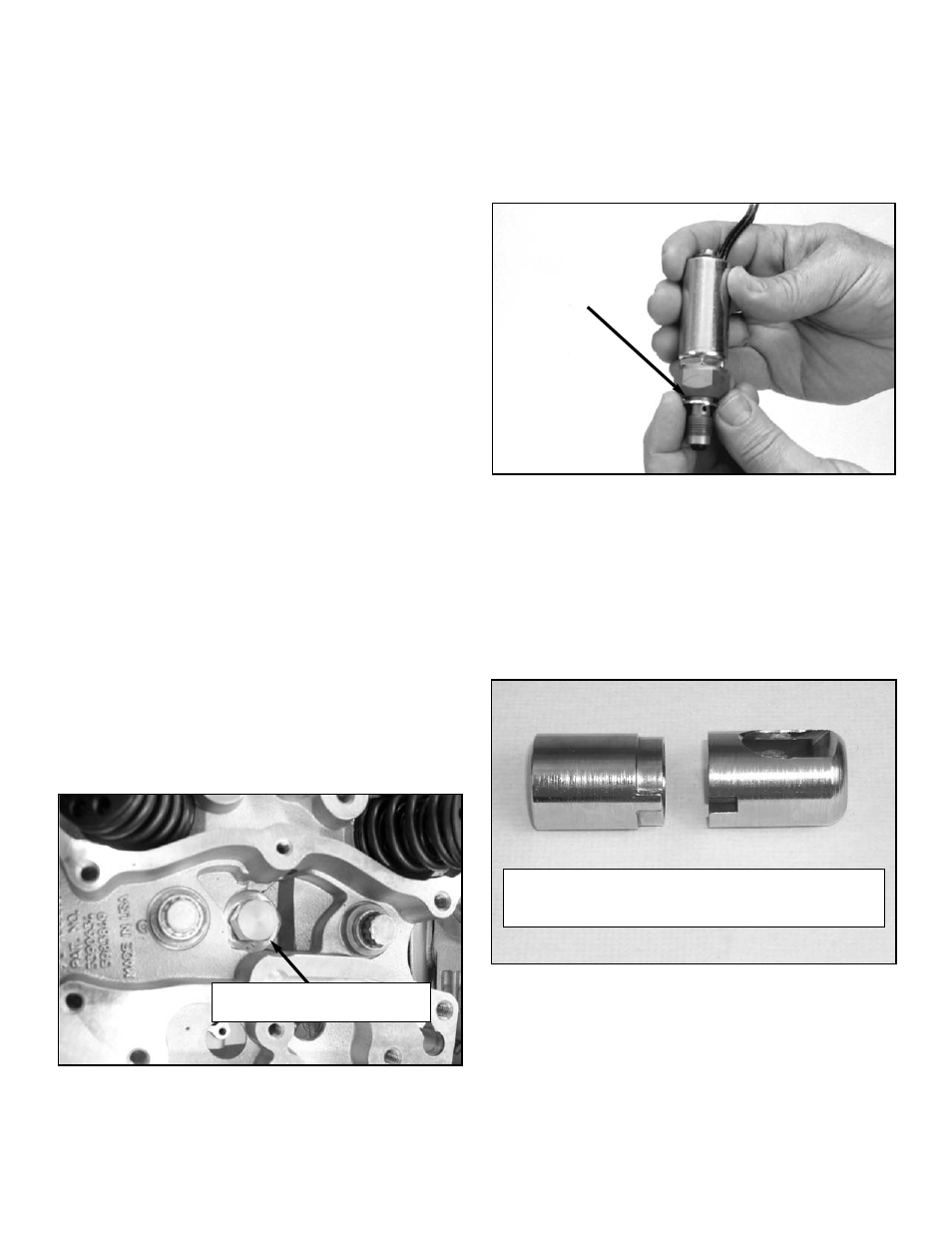

Remove the supplied 14mm hex plug from the top of

the cylinder head. Inspect the machined hole to make

sure that it is clean and free of debris. See Picture 1.

3.

Apply a small amount of anti-seize type thread lubricant

to the threads of the compression release. Compression

releases are identical and can be installed in either

cylinder head.

4.

Make sure that the supplied compression washer is held

in its groove in the valve body. The washer must remain

in this position when the compression release is held in

a vertical position. If it does not stay in position, a very

small amount of white lithium grease between the

washer and the valve body will hold the washer in place

during installation. See Picture 2.

5.

Thread the compression release into the pre-machined

mounting hole. Hand tighten as far as possible. Make

sure the compression washer remains in position until

the compression release contacts the head.

6.

Slide the bottom half of the S&S special socket 53-0046

over the lead wires and onto the compression release

assembly. Position the socket so it is on the hex portion

of the compression release. See Picture 3.

7.

Slide the top half of the special socket 53-0047 over the

lead wires and onto the bottom half of the socket so

that it locks in place.

8.

Make sure the compression washer is seated properly

before final tightening is done. Torque the compression

release to 32-37 ft/lbs.

9.

Remove the socket halves carefully so the lead wire

insulation is not damaged.

2

Picture 1

Picture 2

Picture 3

Remove threaded plug to install

S&S compression release.

Special S&S two-piece compression release socket 53-0045

allows in-frame installation of S&S compression releases

and protects wiring from damage during installation.

Compression washer

must remain in the

groove in the valve

body during

installation.