Caution – S&S Cycle Performance Replacement Cylinder Head Kit for 1984-99 Big Twin Engines and Harley-Davidson Sportster Models User Manual

Page 3

A.

Remove gas tanks and all other parts required to perform top end service.

B.

Remove carburetor, rocker covers, pushrods and pushrod tube assemblies, and cylinder heads

NOTE: Be careful not to introduce any dirt or other foreign material into crankcase during disassembly of engine.

Metal filings, dirt and any other foreign contamination in engine may cause premature wear and/or irreversible damage to

bearings and other internal engine components.

C.

Thoroughly clean and inspect all parts that are to be reused. Any parts that show signs of wear or damage should be replaced.

Insufficient clearance between piston domes and cylinder heads or piston domes and valves will cause damage to pistons, heads

and/or valves. It is the engine builders responsibility to check for adequate clearance regardless of head and gasket combination.

D.

Repeat procedure to check rear piston to cylinder gasket surface relationship.

E.

S&S

®

Stock Replacement heads are designed to work with flat top pistons. If you attempt to use them with any other piston,

be sure to check for adequate clearance.

F.

Coat piston skirts with engine oil and install cylinders.

G.

Spin each head bolt down on its respective stud to be sure threads are clean and free of contamination.

H. Install head alignment dowels in cylinder. (Do not re-use any dowels that are damaged, or have flanges or an O-ring groove

machined into them.)

I.

Place head gaskets onto cylinder and over head alignment dowels.

If the gasket fits close to the dowel pin and there is not room for an O-ring, do not install an O-ring.

If there is room for an O-ring, install one O-ring over each dowel per the note below.

NOTE: There are two sizes of alignment dowel O-ring available: .070" diameter O-rings are to be used with .045" thick gaskets. .0825"

diameter O-rings are to be used with .0625" thick gaskets.

Using thin O-rings with thick gaskets or thick O-rings with thin gaskets may cause oil leaks or possible ruptured head gaskets

around line-up dowels due to incorrect O-ring compression.

J.

Ensure that the head gaskets and O-rings (if used) are correct for the application, then remove them and carefully clean head

and cylinder gasket surfaces with lacquer thinner or equivalent. Gaskets are to be installed clean and dry. Do not use gasket

sealing compounds on cylinder head gaskets.

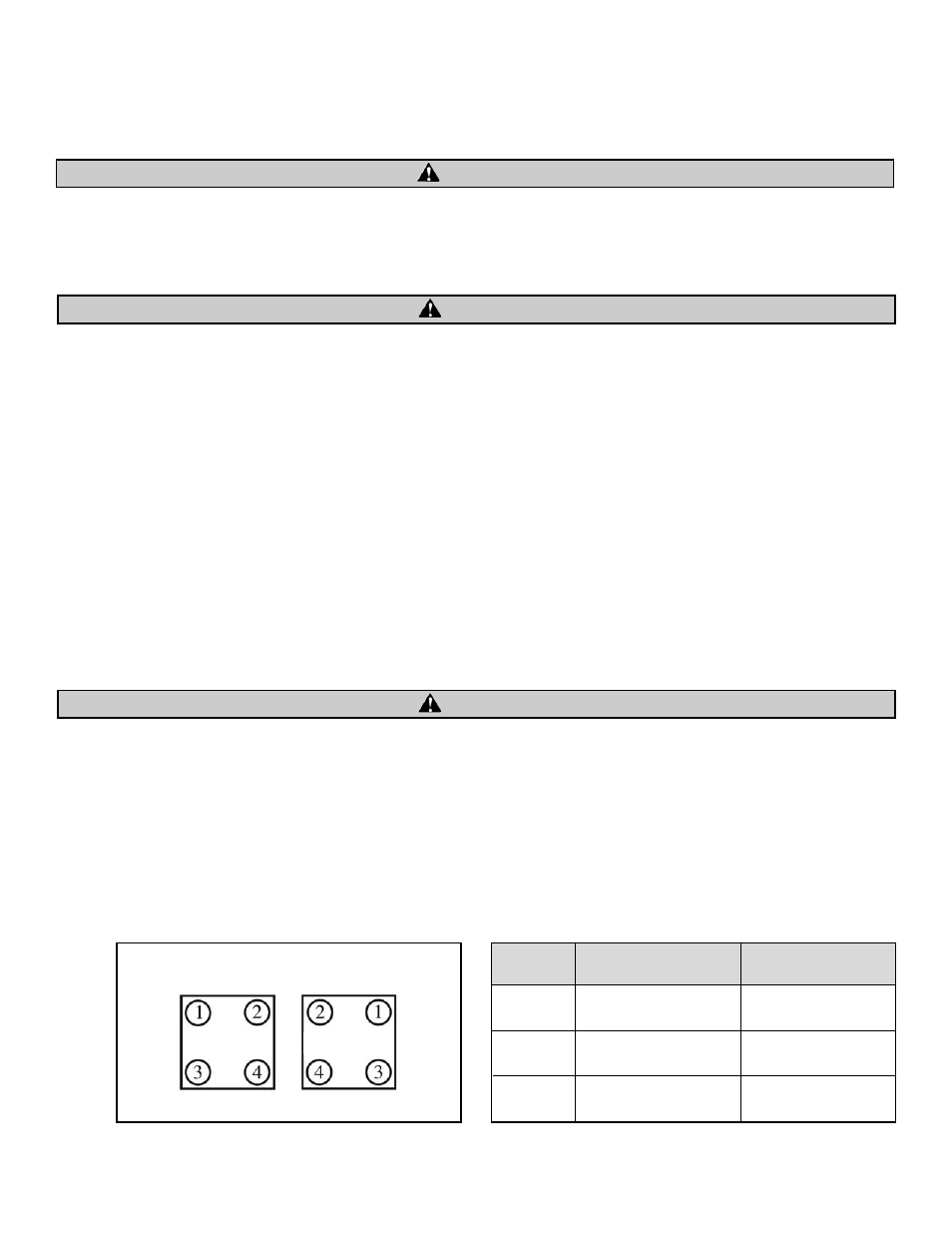

K.

Bolt heads on cylinders. Clean threads of head bolts and cylinder studs. Place one or two drops of oil on threads of each head

bolt just prior to final assembly to reduce friction and insure accurate torque readings. Tighten bolts in stages using crossing

pattern. If using S&S or stock crankcases, follow the the torque and sequence chart. See Figure 1. If using other aftermarket

crankcases, contact the manufacturer for recommended head bolt torque specifications.

3

CAUTION

CAUTION

CAUTION

Figure 1

Stage

S&S

®

Crankcases

Stock Crankcases

Stage 1

8 ft-lbs.

7-9 ft-lbs.

Stage 2

18 ft-lbs.

12-14 ft-lbs.

Stage 3

Turn Additional 90°

Turn Additional 90°

Top View

Driveside

Camside

Rear Head

Front Head