S&S Cycle Piston Rings User Manual

Page 2

2

RING INSTALLATION

1- Ring widths on S&S® pistons may change from time to time. Part

numbers of rings originally supplied with pistons should be

recorded for future reference in the event replacement rings are

required.

2- The majority of ring kits presently supplied by S&S® contain a moly

faced top ring, a cast, reverse torsion second ring, and a three piece

oil ring. This may be confirmed as follows:

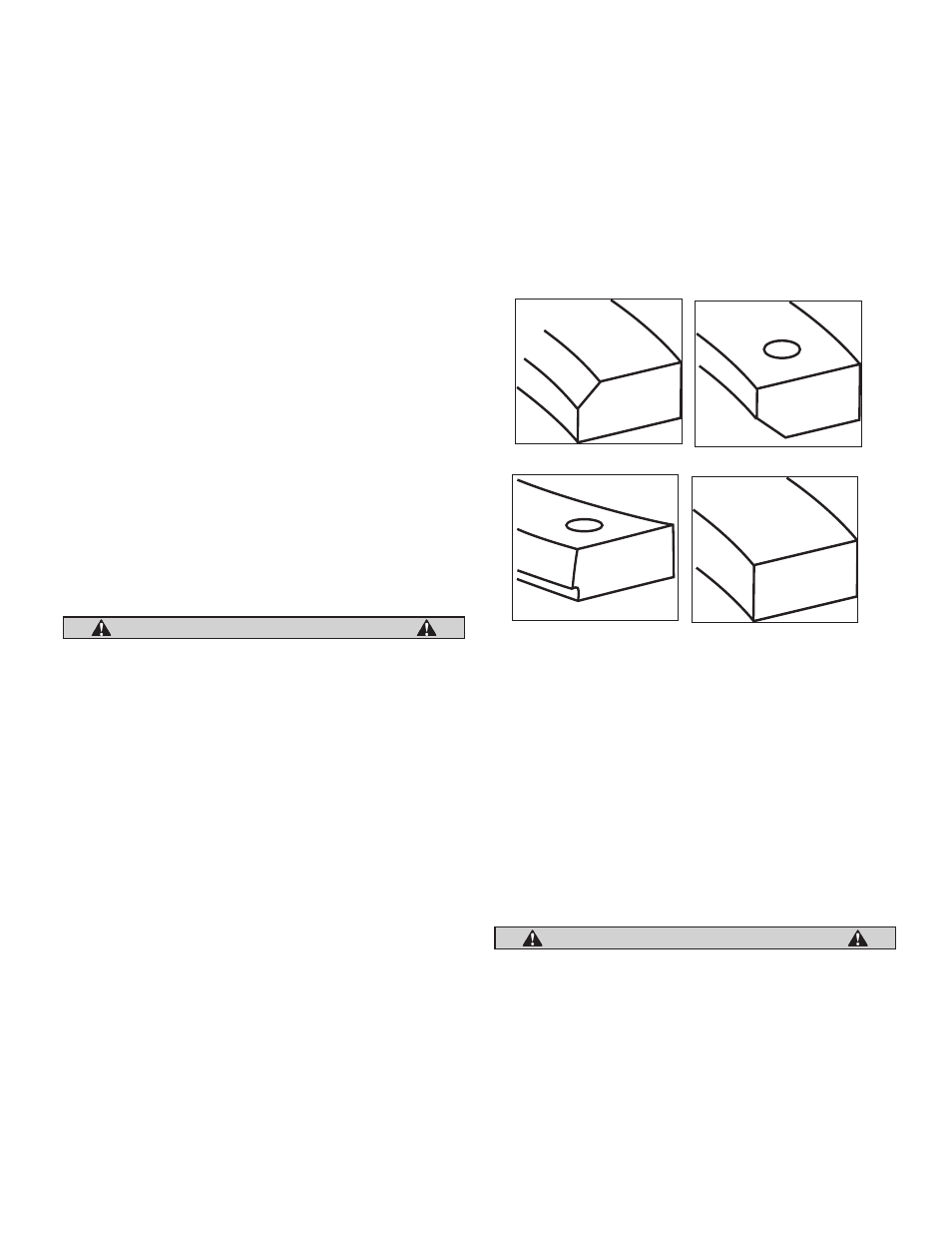

A- Top compression ring has a gray finish that is relatively light in

color, and may or may not have a slight bevel along the inner

edge. See Figure 1. It generally has no dot or other identifying

mark. The light color can best be recognized by comparing

compression rings to each other beneath a good light. Install

light colored ring in top groove, bevel up. If there is no bevel,

ring can be installed either side up.

B- Second compression ring has a darker, charcoal gray finish

and may slight bevel along inner surface, or a hook-like relief

machined on the bottom of the outer diameter. See Figures 2

and 3. This ring may have a dot or letter on the top side. Install

in second or middle groove with dot or letter up. Bevel on the

inner surface or groove on outer diameter will face down.

C- Oil rings are three piece type with two rails and one expander.

Do not shorten expander for any reason! Installation is

straightforward with one rail placed above expander, other rail

below expander. Rails may be shortened to correct gap, but

burrs must be carefully removed.

NOTE: In some cases, same expander is used for several bore sizes. Oversize

rings will not necessarily have a larger expander

CAUTION

Failure to remove burrs may cause engine damage.

Incorrect installation of rings may result in poor performance,

excessive oil consumption or engine damage.

3- Rings supplied in some ring kits may differ from those described in

section #2. Compression rings may be of plain cast iron type, chrome,

or moly faced cast iron.

A- The most common combinations are:

1- Two chrome faced cast rings

2- One chrome faced cast ring & one plain cast ring.

3- One moly faced cast ring & one plain cast ring.

B- Install as follows:

1- Chrome faced or moly faced ring always goes in top groove

2- Plain cast ring usually goes in second groove. Plain cast

type is usually a reverse torsion ring. distinguished by

an inside diameter bevel on one side of ring, and a dot,

letter, or oversize mark on other side. See Figure 2. Some

second rings may have a hook shaped groove machined

around the bottom of the the outer diameter. If two cast

iron compression rings are supplied in a set, check to see if

one has mark and bevel or hook shaped groove. These rings

always go in second groove with marking up if present and

bevel or groove facing down.

C- The following rules apply to compression ring identification and

placement. Rules are listed in order of priority. In other words, if both

Rule #2 and Rule #4 apply, for example, Rule #2 will be followed

and Rule #4 ignored.

1- Chrome or moly ring goes in top groove.

2- Cast iron regular or reverse torsion ring goes in second

groove.

3- Any identifying pip marks, dots, letters, or oversize marks

go to top of piston.

4- Ring with one dot goes in top groove, ring with two dots

goes in second groove.

5- If both rings are identical and have one dot or two dots,

either ring can go in either groove.

6- If ring has dot or letter and inside diameter bevel, dot or

letter goes to top of piston. See Figure 2 and 3.

7- If ring has no dot but does have inside diameter bevel,

bevel goes to top of piston. See Figure 1 below.

8- If ring has no dots and no bevel, it can go either way. See

Figure 4 below.

4- Ring Gap Measurements

A- Compression ring end gap on big twins with 31⁄2" bore is .014"

to .022".

B- End gap on all other compression rings is .016" to .024".

C- Oil ring rail end gap on big twins with 31⁄2" bore is .015" to .035".

D- Oil ring rail end gap on all others is .015" to .035".

E- Compression ring end gap on big twins with 41⁄8" bore is .017"

to .025".

F- Oil ring rail end gap on big twins with 41⁄8" bore is .015" to .035".

NOTE: In certain instances, the next oversize ring set may be supplied with

pistons, for example + .060" oversize rings with +.050" pistons. In this case

end gaps must be measured and rings filed as necessary. Ends must then

be carefully deburred.

CAUTION

Failure to deburr rings may result in engine damage.

Piston Series 92-1210, 92-1550, 92-1556, and 92-1560 have a

ring support rail that needs to be installed before any other

rings are installed.

Figure 2

Figure 1

Figure 4

Figure 3