S&S Cycle Pistons 103 User Manual

Page 2

2

Cylinder Preparation and Suggested Clearances:

1- Cylinders must be bored and honed before pistons kit can be assembled. Piston diameter can not be measured due to the break-in coating on

the pistons.

2- Bore each cylinder to within 0.001” of the final bore diameter. Final hone the cylinder bore to 3.875 +/- 0.0005”. Using these specifications the

piston to cylinder wall clearance will be 0.0015” +/-0.0005”.

CAUTION

WARNING

Boring and honing must be performed by experts to assure that the cylinder bore is perpendicular to the gasket surfaces. All S&S® and

Harley-Davidson® motorcycle cylinders must be held by torque plates during the boring and honing operations. Failure to use the torque

plates will result in cylinder distortion. A piston ring compressor must be used to install the piston and ring assembly in the cylinder.

Improper installation will cause engine damage. Torque the cylinder head bolts according to the service manual recommendations.

Piston Ring Installation:

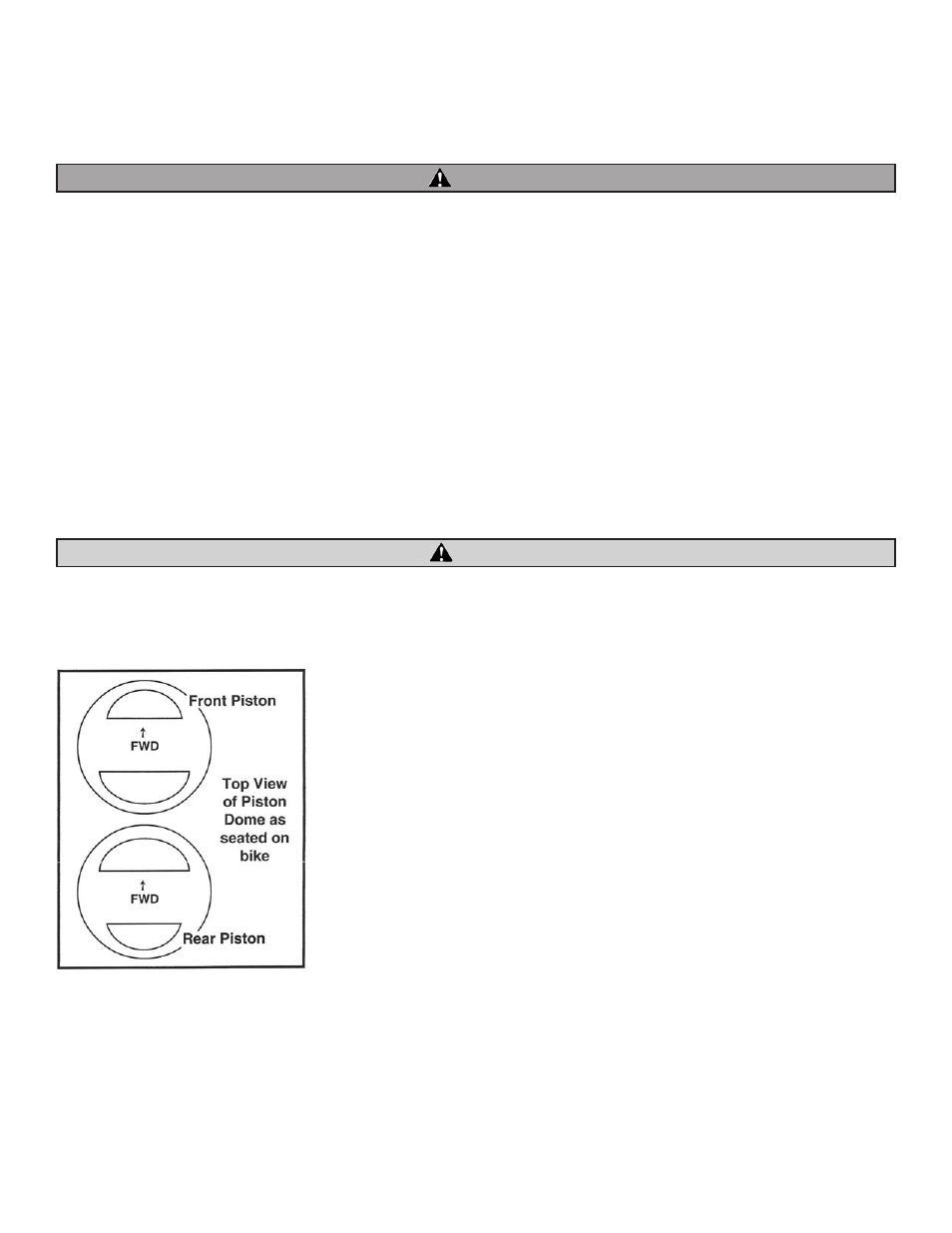

NOTE: The arrow on top of S&S pistons must point forward toward the front of the motor after installation.

1- Piston to cylinder fitment is critical. Follow the advised clearances given below for best results. Always use new gaskets and torque all cylinder

head bolts to the manufacture’s specifications. In some instances, the cylinder head bolts may have to be re-torqued after the break-in

procedure to ensure proper head gasket seal. The manufacture’s break-in procedure must be follow or engine damage could occur.

• 1st and 2nd piston ring end gap: 0.017” – 0.025”

• 3 piece oil ring end gap: 0.010” – 0.040”

Modified Cams Or Altered Cam Timing:

1- Most S&S pistons are machined with valve pockets that are deeper and larger than stock. These pockets provide adequate valve clearance for

most modified or high lift cams. If is very important that the valve-to-piston clearance be checked with every modified cam installation. This

is necessary due to the many variations in cam profile and the selected cams’s timing.

If the compression ratio of the engine is greater than 10.0:1. A high performance ignition system is suggested.

•

If abrasive grit is not removed from the cylinder wall after machine operations, engine damage could occur. Wash the cylinder with warm

•

soapy water, then swab with clean motor oil on a clean rag until all residue is gone. Washing with a solvent will not remove the abrasives

from the finished cylinder walls. Blow compressed air through oil passages during the cleaning process to remove particulates.

Each cylinder should be deburred on top and generously chamfered on the bottom for ease of piston and ring installation. Finish hone with a

280-400grit hone. A 45° cross hatch finishing pattern is important for best results.