S&S Cycle Replacement Pistons 80 For Harley-Davidson Evolution Big Twin Engines User Manual

Page 2

1- IMPORTANT INFORMATION

• For maximum piston and ring life, fit pistons using close fit dimensions.

Close fit requires absolute adherence to new engine break-in as

described on page 3.

• For immediate drag strip use, fit pistons using loose fit dimensions.

Break in rings and pistons with 50 easy miles if possible. Piston and ring

life will be reduced with loose fit dimensions.

• These pistons can be used in either the front or rear cylinder, however

they must be installed with the arrow on the dome pointing to the front

of the engine due to the offset wristpin. If pistons are received from S&S®

fit to cylinders, pistons must be installed in cylinders they were fit to.

Failure to follow instructions and perform required clearancing,

installation and/or break-in procedures may result in damage

to pistons and/or other engine components not covered under

warranty.

2- FITTING PISTONS

a. Measure all pistons at widest point across thrust face, perpendicular

to wristpin hole. Several measurements should be taken to locate

widest point. Typically, approximately 1⁄2" below level of wristpin

hole.

b. Follow procedure recommended in Harley-Davidson® service

manual for boring and honing stock bore big twin cylinders.

Torque plates must be used to simulate compressive stress in an

assembled engine. Cylinders will distort when installed if torque

plates are not used.

c. It is recommended that cylinders be bored to .001"–.002" smaller

than required final size.

d. Hone cylinders to size. Final hone with #220-#280 grit stones.

e. Thoroughly clean cylinders to remove all metal or abrasive

particles.

NOTE: In all cases it is the engine builder’s responsibility to confirm proper

clearances when assembling an engine. This is especially critical with

performance components such as higher compression pistons and high

lift camshafts. In addition to clearances mentioned, .060” valve-to-piston

clearance must be confirmed.

Failure to establish proper clearances can result in severe engine

damage not covered under warranty.

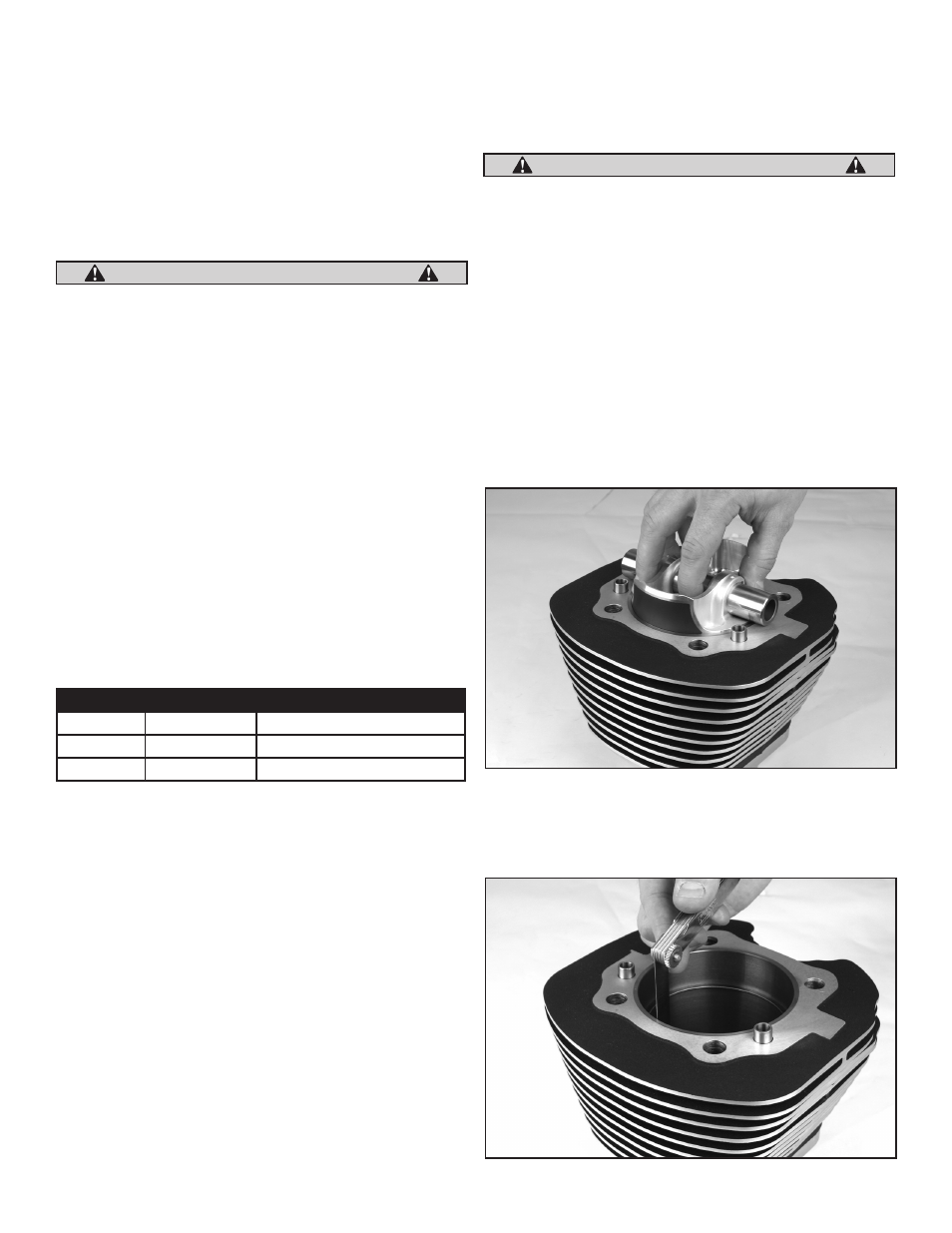

4- PISTON RING INSTALLATION

a. Check ring end gaps by sliding rings into the top of the cylinder

bore, Use a piston or caliper to ensure that the ring is placed

squarely in the bore. See Picture 1.

b. Measure the ring end gap with a feeler gauge. Compression ring

end gap should be .014" to .022", and oil rail end gap should be .015"

to .035". See Picture 2.

c. If end gap is too tight, carefully file the ends of the piston rings to

achieve correct end gap. Remove any burrs from the end of the

ring. Do not file oil rail expanders.

3- PISTON INSTALLATION

a. Thoroughly clean wristpin before installation, paying particular

attention to bore. Pass clean, lint-free cloth back and forth through

wristpin bore several times to insure removal of contaminants such

as heat treating oxide scale.

b. Wristpin keepers included with these pistons are circlip type and

must be installed with a snap ring pliers. Ensure that grooves in

piston are free of burrs and foreign matter.

c. Install one wristpin clip in the piston and start the wristpin in the

wristpin bore of the piston on the other side.

d. Hold the piston on the end of the connecting rod and slide the

wristpin through the wristpin bushing in the rod until it seats

against the wristpin clip in the piston.

e. Install the second wristpin clip, and make sure both wristpin clips

are properly seated.

f. Repeat for other piston.

g. Check piston to piston clearance at closest point near bottom of

stroke. Clearance should be at least .060".

h. Check piston to flywheel clearance a lowest point of piston travel.

Clearance should be at least .060". Compare replacement pistons

with ones being replaced and make corrections accordingly.

2

CAUTION

CAUTION

Piston Fit Specifications

Close Fit

.0010"-.0015"

Best engine life, quiet operation

Loose Fit

.0020"-.0025"

For Immediate hard service

Wristpin Fit

.0007" to .0014"

Pre-fit, for reference only

Picture 1

Picture 2