Top view cam side drive side – S&S Cycle Piston and Big Bore Kits 98 and 107 for 1999-06 and 2007-14 Big Twins User Manual

Page 4

4. Piston Installation

NOTES

• Pistons are identical and can be installed in either cylinder.

• CAUTION: THE PISTONS MUST BE ORIENTED SO THAT THE VALVE

RELIEFS MATCH THE CORRESPONDING VALVES. THE INTAKE

VALVE RELIEF IS LARGER THAN THE EXHAUST VALVE RELIEF.

THE 107" PISTONS HAVE A NOTCH ON THE BOTTOM OF THE

SKIRT, THIS NOTCH MUST BE INSTALLED TOWARD THE CENTER

OF THE ENGINE. THE 98" PISTONS DO NOT HAVE A NOTCH AND

MUST BE INSTALLED WITH THE VALVE RELIEFS ORIENTED TO THE

APPROPRIATE VALVE.

• Check piston pin to connecting rod bushing clearance. Clearance

should be between 0.0007" and 0.0012". Bushing should be replaced

if clearance exceeds 0.002".

a. Place rubber tubing over the cylinder studs to prevent damage to

the pistons and rings during assembly.

b. Place a clean sheet of plastic over the crankcase openings to

prevent anything from dropping into the crankcase.

c. Install one of the piston pin clips into each of the pistons according

to the instructions included in the piston kit.

d. Lightly oil the piston pin, piston pin bore and upper connecting rod

bushing with clean 20W-50 oil or assembly lube.

e. Hold the piston over the connecting rod with the piston facing the

correct direction and the piston pin bore and upper bushing bores

lined up.

f. Install the piston pin through the piston pin bore and through the

connecting rod bushing until the pin contacts the clip.

g. Install the other piston clip. Ensure that both clips are fully seated.

h. Repeat procedure for the rear piston.

5. Cylinder Installation

a. Bring the front cylinder to TDC.

b. Apply a light coating of oil to the piston and rings.

c. Lightly oil the new cylinder base o-ring and install on the cylinder.

d. Lightly oil the new o-rings for the lower cylinder deck alignment

dowels and install.

e. Verify that the ring gaps are orientated correctly, refer to Picture 5a.

f. Remove the rubber tubing from the cylinder studs.

g. Compress ring pack by using a suitable ring compressor. If possible,

position the ring compressor so that you can see the oil expander

gap during installation. Picture 5b.

h. Install cylinder on piston, making sure not to overlap oil ring

expander.

i. Remove ring compressor.

j. Remove plastic sheeting covering crankcase.

k. Slide the cylinder down until it seats against the crankcase.

l. Rotate the engine until the rear cylinder is at TDC.

m. Repeat procedure for the rear cylinder.

6. Cylinder Head Installation

Head Gasket Tightening Torque Specifications

Multi layer steel (MLS) head gasket, PN 106-3714, 0.045" thick or PN 900-

0216, 0.030" thick

a. Check surfaces for flatness and imperfections, an excessively rough

finish may cause gasket failure.

b. Check all hardware for defects. Clean all threads and lubricate with

clean oil. Lubricate the underside flange of the head bolts with

clean oil (wipe away excess).

c. The head bolts are two different lengths. The short ones go on the

spark plug side; the long ones go on the pushrod side.

d. Place the head gasket on the cylinder and locate the gasket using

the cylinder head alignment dowels. Either face of the gasket can

be up, there is not a specific top or bottom to the gasket.

NOTE: Do not use the cylinder head alignment dowel O-rings with MLS

head gasket.

e. Once the gasket is in place, make sure that it fits the bore. The

gasket should not hang into the bore or combustion chamber area.

f. If using cylinder heads other than stock, check the brass rivets

of the MLS gaskets to ensure the rivets do not interfere with the

sealing surface in any way.

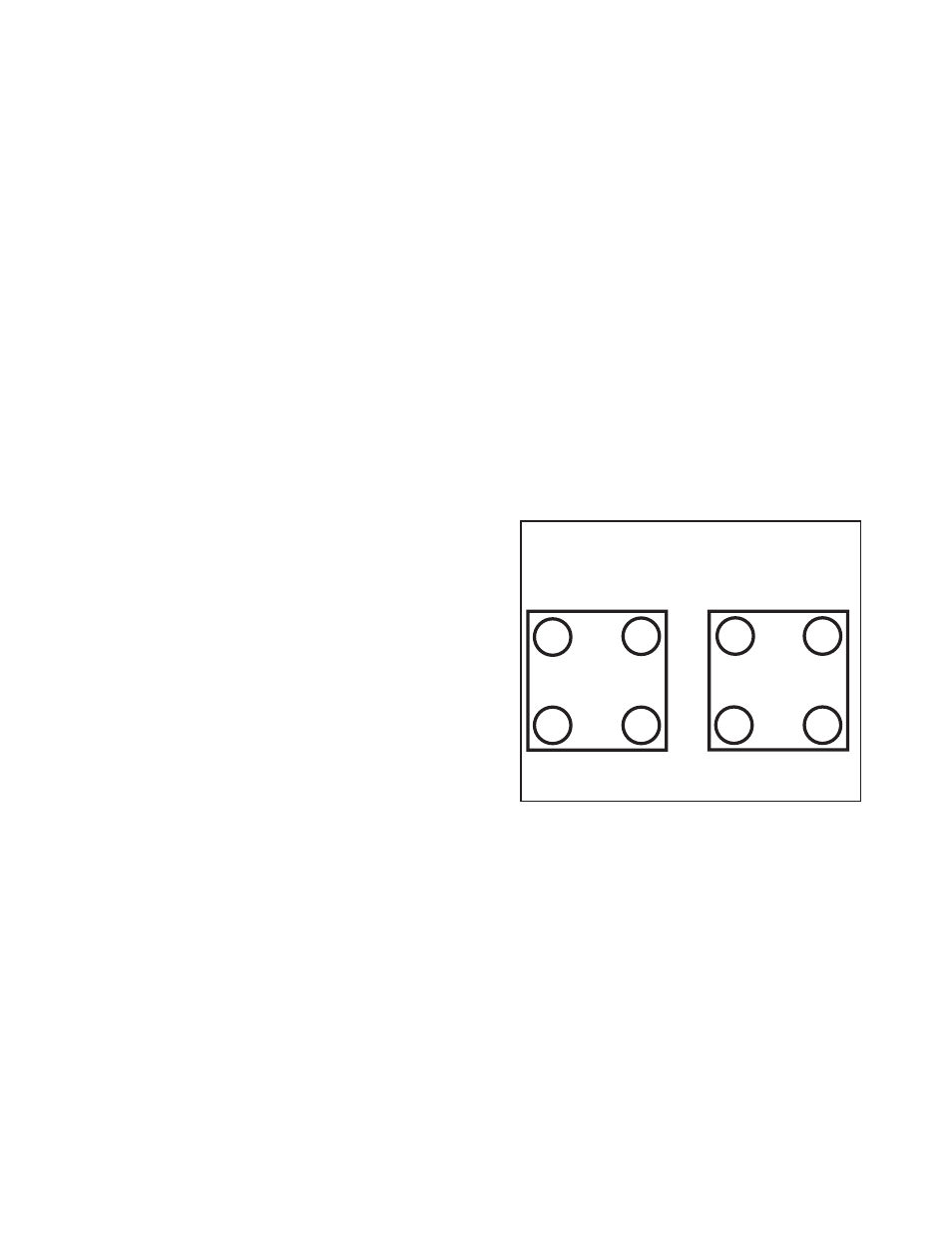

g. Important! In order to properly seal the head gasket, the head

bolts must be torqued in the sequence shown in the next step,

fully loosened, then torqued again a 2

nd

time. Follow the head

tightening sequence in the next step then fully loosing the head

bolts ¼ turn at a time in the sequence shown in Picture 6 until fully

loose. Repeat the tightening sequence in step h below, a second

time.

h. Tighten the head bolts according to the following procedure, start

with the front head then the rear head.

i. Tighten each bolt finger tight using the sequence in Picture 6.

ii. Tighten each bolt to 10-12 ft-lbs using the sequence.

iii. Tighten to 15-17 ft-lbs using the sequence.

iv. Finally, tighten the bolts an additional ¼ turn (90˚).

3

4

2

1

4

3

1

2

Top View

Cam Side

Drive Side

Front Cylinder

Rear Cylinder

7. Final Assembly

Assemble the remaining items according to the Harley-Davidson

service manual specific for your motorcycle.

8. Tuning

S&S big bore kits increase the displacement and compression ratio of

your engine. The fuel and ignition systems must be calibrated for these

changes before the engine is driven and break-in is attempted. It is

recommended that a performance carburetor such as the S&S Super E

or G be used with the correct jetting for the engine size for carbureted

models. Fuel injected engines must be tuned using a replacement

ECU such as the S&S VFI module, or an aftermarket tuner such as the

DynoJet® Power Vision® tuner.

NOTE: The S&S VFI module is not compatible with 2008–up Touring

models with electronic throttle control. S&S recommends the Dynojet®

Power Vision® tuner for these applications.

4

Picture 6