S&S Cycle Camshafts For 1986–2013 Harley-Davidson Sportster Models User Manual

Page 3

NOTE – Pinion gear information:

• 1986–’87 engines with stock flywheels and 1986–’99 engines with S&S

flywheels have a splined pinion shaft that requires a 1986-’87 style

splined pinion gear. The gear profile is compatible with all S&S cams

except the 482 cam.

• 1986-’99 engines with stock flywheels have a keyed pinion gear with

the same gear tooth profile as 1986–’87. This profile is compatible with

all S&S cams except the 482 cam.

• 2000–up engines with stock flywheels require a keyed pinion gear with

1986–’99 style gear profile to match all S&S cams except the 482 cam.

• The S&S 482 cam is only available for 2000–up engines and has the

stock 2000–up gear profile. It can be installed in 1988–’99 engines with

stock flywheels if a 2000-up style pinion gear is installed to match the

drive gear tooth profile.

a. Remove pinion gear nut. Use crankshaft looking tool #HD-

43984 or equivalent, or shift the transmission into gear with the

rear tire on the ground or lift surface.

b. Slide pinion gear off pinion shaft.

c. Clean pinion shaft and threads.

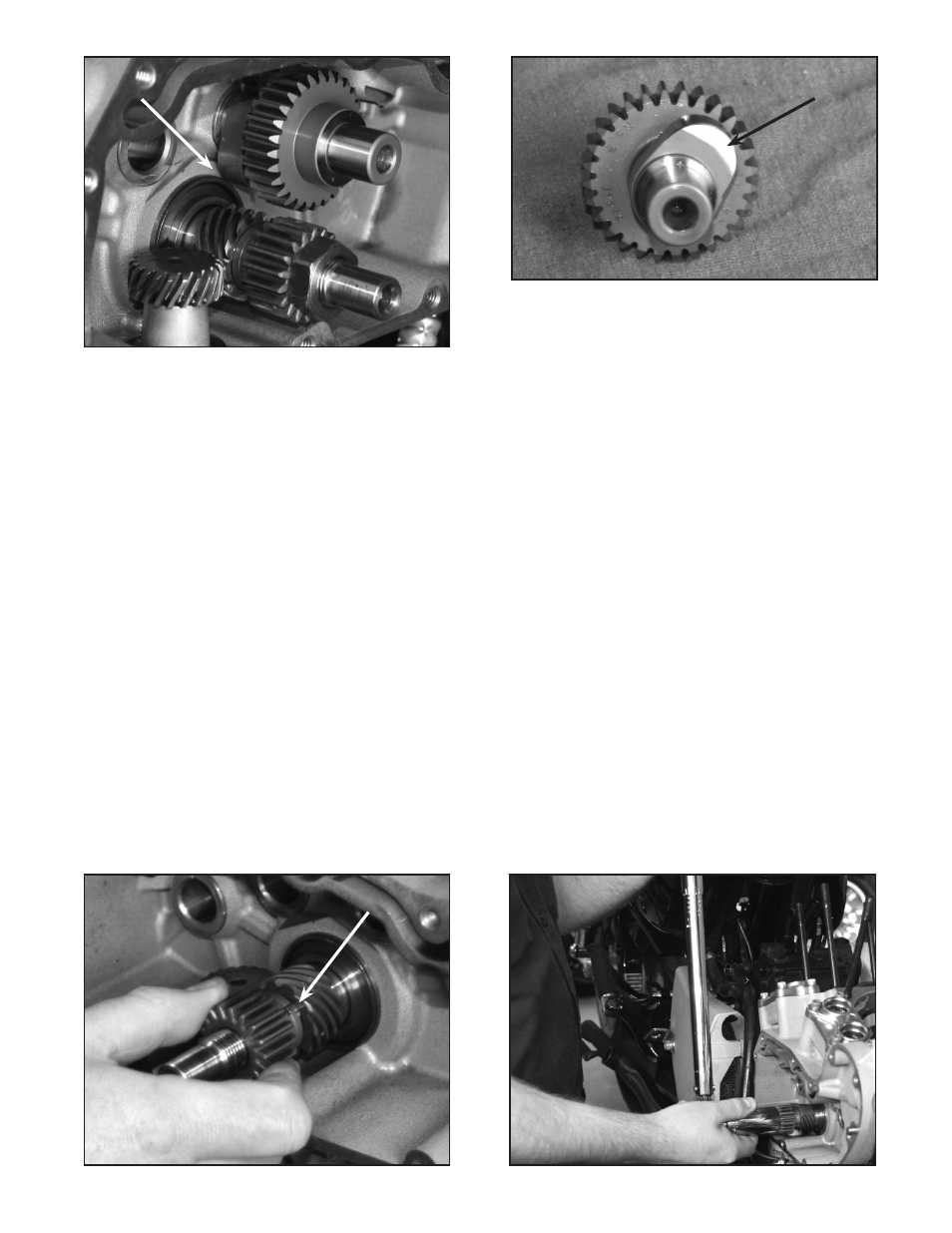

d. Install the new pinion gear, making sure to align the slot in the

gear with the pinion shaft key. Picture 4, below left.

e. Install crankshaft locking tool or shift transmission into gear.

f. Apply red thread locker to pinion shaft nut and torque to 19-21

ft-lb. Picture 5, below right. Turn pinion nut an additional 15°

to 19°. Picture 6, next page.

Installation Steps

1. Remove fuel tank, rocker covers, rocker arms, pushrods, gear

cover, tappet covers, tappets, and cams. Consult the appropriate

Harley-Davidson® service manual for correct procedures

2. Inspect all cam bushings/bearings for damage or wear and replace

if needed.

3. If pinion gear replacement is required to match gear pitch on

#2 cam, remove pinion gear at this time. See Picture 8 for cam

numbers.

4. Place each cam in cam bearing or bushing in crankcase, and spin

the cam 360° to check for lobe to crankcase interference. Normally

interference will be found only in high lift cams like the 555 or

600 cams. S&S 482 or 500 cams should not have any crankcase

clearance issues. If cam lobe contacts tappet guide area clearance

the crankcase. If the rear of the #3 cam lobe contacts steel bearing

insert, Picture 2 above, clearance the back of the cam lobe by

grinding off the minimum material to eliminate interference.

Picture 3, above right. If grinding crankcase, tape off cam

bearings to keep debris out of crankcase, and clean out any debris

from the cam chest.

NOTE – If pinion gear is still on pinion shaft, #2 cam clearance can

be checked by raising rear wheel of bike and turning rear wheel with

transmission in gear.

5. Install correct pinion gear. (If required. See note at right)

3

Picture 2

Picture 4

Picture 5

Picture 3