S&S Cycle Dual Valve Spring Kits for 1984–12 Harley-Davidson Big Twin and 1986–12 Sportster Models User Manual

Page 2

2

The safety of the motorcycle rider is dependent of proper installation of this product. If you are not certain of your capabilities or do not

have the correct tools for this installation, please consult a shop to have it done. Improper installtion of this product could result in injury

or death to the rider.

S&S® valve spring and collar kits part numbers 90-2277 and 900-0420 accommodate valve lifts up to .585" using standard length, 5⁄16" diameter and

7mm diameter valves, and are compatible with stock style valve guides. These spring kits are available with S&S Super Stock® cylinder heads for

Harley-Davidson® Evolution® and Twin Cam 88® engines.

NOTE: Spring kit components in these kits are not interchangeable with those from other S&S valve spring kits.

Mixing of valves, springs or collars between S&S dual springs and other S&S spring kits can cause extensive engine damage not covered

under warranty.

Installation of part numbers 90-2277 and 900-0420 spring kits do not usually require modification for S&S or most stock heads. Exceptions are Buell®

Thunderstorm heads and certain Sportster® models and big twin heads with different machining in valve spring pockets. In such cases, removing a

small amount of material (approximately .030") from O.D. of S&S bottom collar should allow collar to rest flat in spring pocket for correct installation.

It may be necessary to machine the valve spring pocket deeper to achieve the correct installed height when installing springs in Twin Cam 88®

cylinder heads.

Spring pressures are as follows at 1.800" installed height: Closed valve - 130 lbs; .585" lift - 325 lbs.

SPRING INSTALLATION PROCEDURE

1- Remove heads from engine and disassemble. If cylinder heads/valves are to be reconditioned, proceed at this time according to standard

procedure. Refer to Harley-Davidson® service manual as necessary.

2- Place lower spring collar in valve spring pocket in head. Place spring on collar. Collar must sit flat on cylinder head and spring coils must not

contact sides of spring pocket in head. If necessary, machine lower collar and/or spring pocket to obtain minimum clearance of .030". Do not

modify spring in any way.

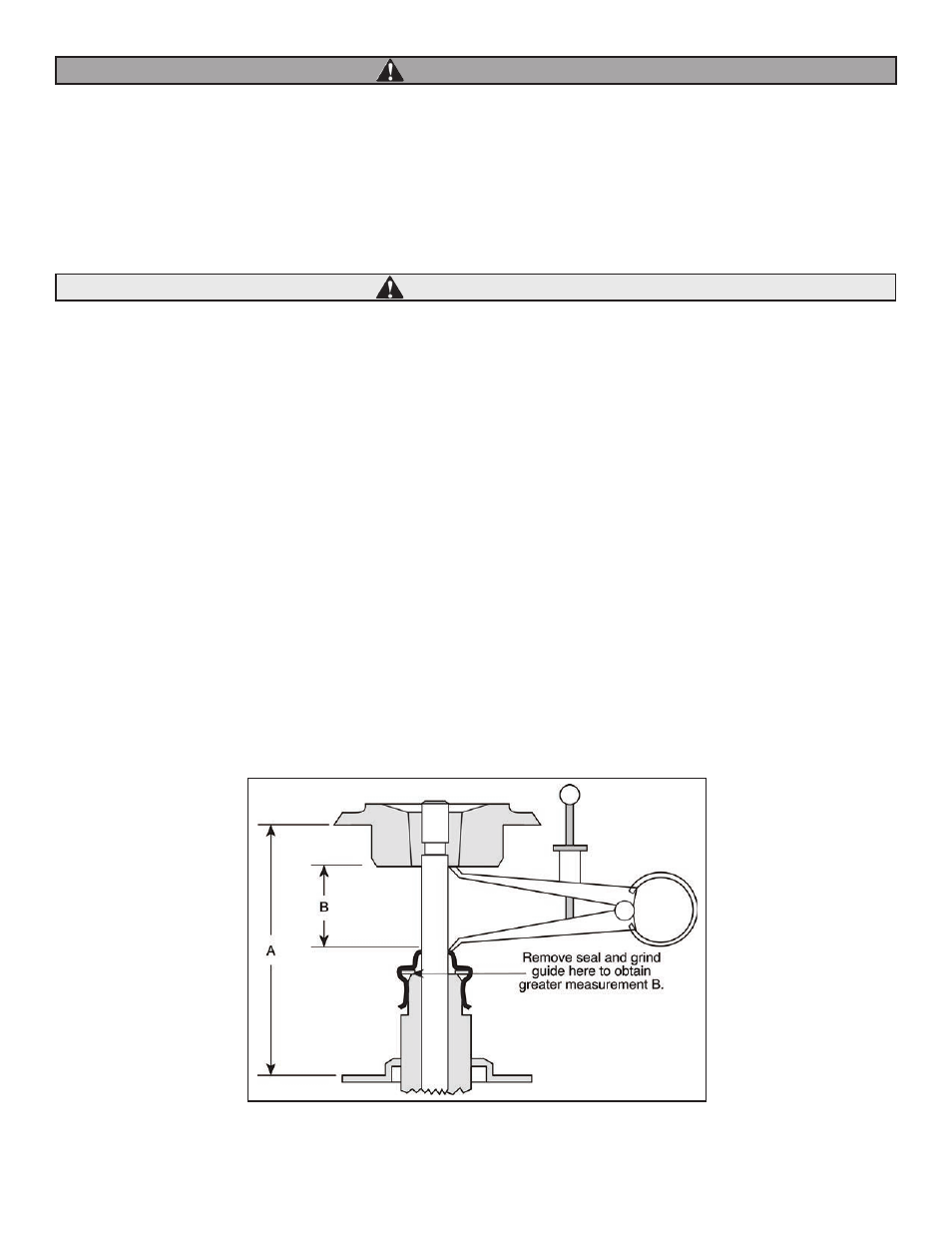

3- Using following procedure, determine installed spring height and clearance between top collar and valve guide.

A- Lubricate valve stem and install valve in guide.

B- Install bottom collar, valve seal, top collar, and valve keepers. Pull top collar tightly against keepers to seat keepers in collar.

C- While holding valve firmly against seat in closed position, measure installed spring height (distance between lower valve spring seating

surface and outside step of top collar). See Figure A, Dimension A. Record measurement.

D- Measure distance between top collar keepers and top of valve guide or seal (if applicable). See Figure A, Dimension B. Distance must be

at least .060" greater than valve lift of cam to be used. If dimension B is not .060" greater than valve lift, valve guide must be shortened to

obtain required clearance.

WARNING

CAUTION

Figure A