S&S Cycle OHV BT and KN-Series 1936-47 Flathead Power Rocker Arms and Rocker Shafts User Manual

Page 2

2

ROCKER ARM REBUILD

S&S® uses specially machined and indexed rocker arm bushings, a rebuild may be more the an average shop or individual can handle, contact S&S

Tech services for more information.

1- To check the wear limits use the chart below.

2- The function of the shaft to bushing tolerance is oil control to the top end, we do not recommend exceeding the wear limit, however, if you are

not experiencing oil flooding to the top end, it is unlikely to need to replace the rocker arm bushings unless they are damaged or show unusual

or uneven wear.

NEW KN ARM REAM

NEW KN SHAFT

Top of Tolerance

0.55165

Top of Tolerance

0.5500

Bottom of Tolerance

0.55085

Bottom of Tolerance

0.5495

Total Tolerance

0.0008

Total Tolerance

0.0005

Nominal Diameter

0.55125

Nominal Diameter

0.54975

NOMINAL NEW

0.0015

Nominal Clearance

0.00075

Nominal Gap Around Shaft

LOOSEST NEW

0.00215

Max Clearance

0.001075

Max Gap Around Shaft

TIGHTEST NEW

0.00085

Min Clearance

0.000425

Min Gap Around Shaft

LOOSEST AT WEAR LIMIT

0.00415

Max Clearance

0.002075

Max Gap Around Shaft

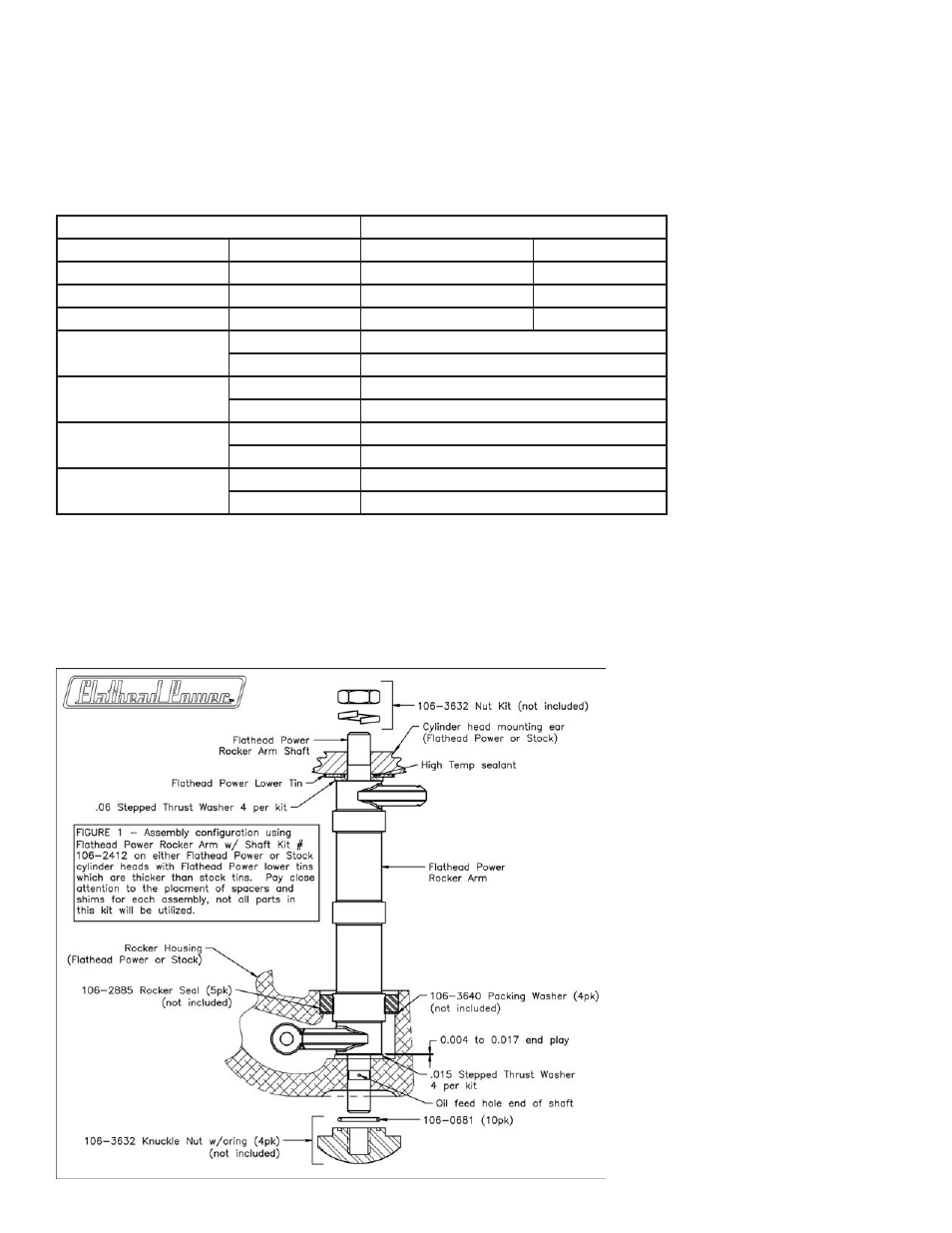

ROCKER ARM AND HOUSING INSTALLATION - GENERAL

1- Determine your usage per figures 1, 2 or 3. Assemble rocker arms as shown for your application, note the oil hole end of the shaft must go in

the rocker housing in order to properly oil the top end.

2- Follow installation Figure 1a.