Caution – S&S Cycle Spring Kit 90-2053 (Fits all Panhead and Shovelhead Engines) User Manual

Page 2

The components of this kit are designed to be used together and

must not be mated with stock springs or retainers or springs or

retainers of another brand. The reasons are:

1.

S&S

®

springs are wound in a different direction than stock

springs.

2.

S&S inner springs are larger in diameter and longer than

stock springs.

3.

S&S outer springs are longer than stock springs.

4.

S&S aluminum top retainers are designed to correctly

accommodate the larger diameter of the inner springs and

longer length of both S&S springs.

INSTALLATION INSTRUCTIONS

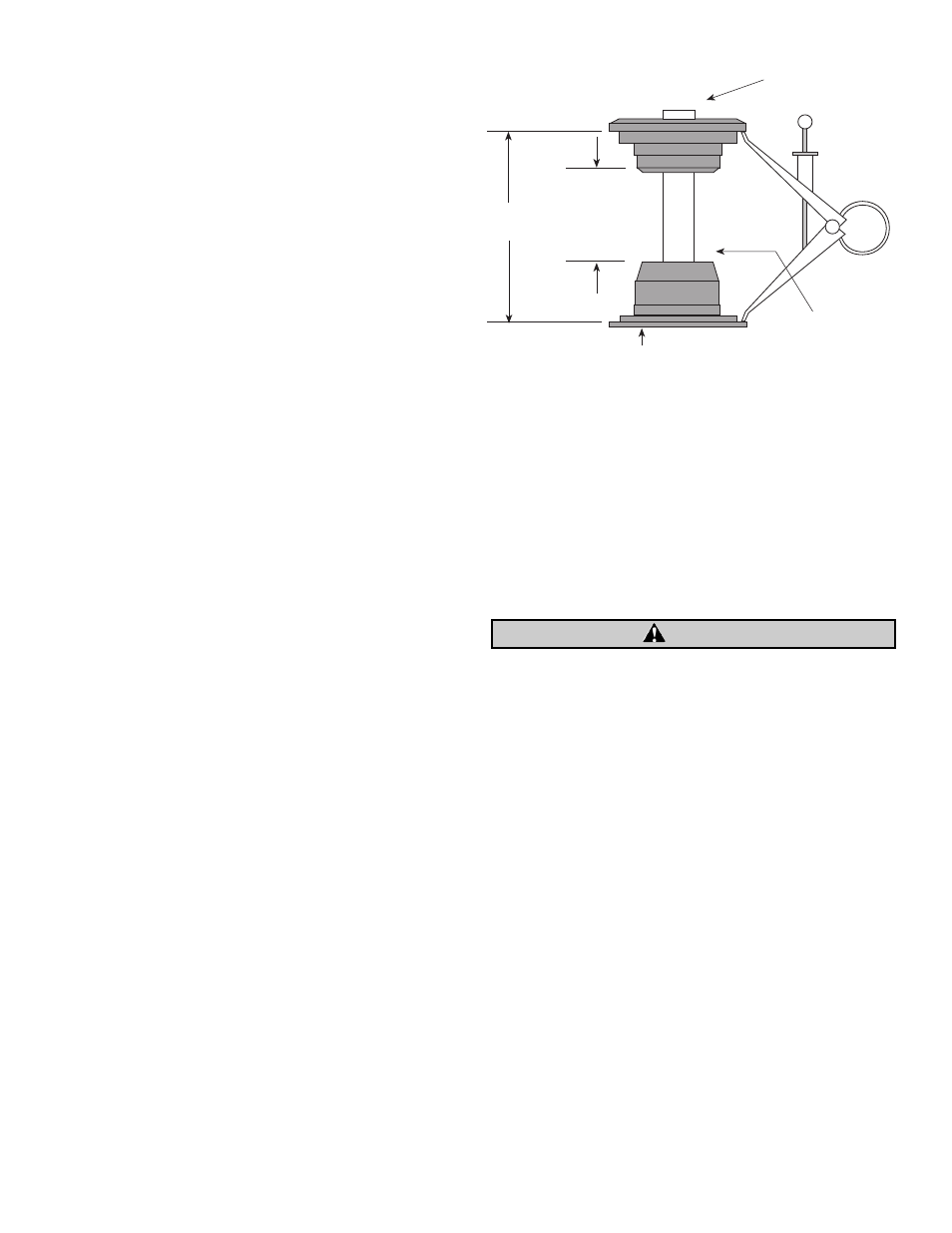

1.

Assemble one valve at a time using stock bottom retainer,

valve guide seal (if equipped with seal), S&S aluminum top

retainer and stock Harley-Davidson

®

keepers as shown in

Figure 1. Tap valve stem with soft hammer at top retainer

to seat stem and keepers.

2.

While pulling up on top retainer to hold valve closed, take

measurements A and B and record them. Perform this step

for each valve. Identify and separate collars and valves so

they can be installed in same position from which you took

measurements. On late heads with valve guide stem seals,

take measurement B to top edge of seal.

3.

Measurement A will normally fall in range shown in Figure

1. This range will provide enough clearance to run cams

with lifts as high as .550".

A.

If measurement A is less than 1.490" Material must be

removed from underside of bottom spring retainer

either from shoulder where retainer contacts guide or

from flat where retainer contacts head. Up to .050" can

be removed from retainer where it contacts shoulder of

guide. If material is removed from this area, retainer

must be installed on guide and checked for contact

between flat of retainer and head. On these installations

retainer must not contact head. Grind head at points of

contact to obtain clearance. On installations where

retainer rests on head instead of guide, up to .050" can

be surface ground from flat of retainer to gain necessary

clearance. Cam installations with lifts greater than .550"

require measurement A to equal 1.505" plus cam lift

minus .550". Example: Cam to be used has lift of .575".

Measurement A = 1.505" + .575" - .550" or 1.530". Basic

rule of thumb - Measurement A must equal length of

coil bound spring + cam lift + .020" minimum.

B.

If measurement A is more than 1.520" - Shims may be

fabricated and placed between guide shoulder and

retainer or retainer and head. Shimming is

recommended particularly in racing applications. On

most street engines where higher rpm usage is limited

shimming is left to discretion of builder.

4.

Measurement B will normally be less than .600" to .620"

shown in Figure 1.

This range will provide enough

clearance to run cams with lifts as high as .550". Subtract

measurement B recorded earlier from .610" for each valve

and grind tops of valve guides. Remove only the difference

in measurements. Carefully remove burr on inside diameter

of guides before installing valves so as not to scratch valve

stems. Just barely break corners on outside diameters of

exhaust guides. Contour outside diameters of intake guides

in engines equipped with valve guide seals to original

shapes. Cam installations with lifts greater than .550"

require measurement B to equal cam lift plus .050" to .070".

Example: Cam to be used has lift of .575". Measurement B =

.575" + (.050" to .070") or .625" to .645".

5.

Perform steps 1 and 2 again and compare measurements with

ones previously recorded. Cams with lifts as high as .550" may

be used when A is 1.490" to 1.520" and B is .600" to .620".

NOTE: Valves sunk deep in seats cause rocker arms to contact valve

stems at a different angle. In extreme instances edge of rocker

arm may contact outside edge of top valve spring retainer at valve

closed position. This causes top retainer to rock which may result

in collar failure. If there is any doubt whether contact exists, we

recommend that rocker arm to retainer clearance be checked.

Improper clearance between moving parts may cause contact

and damage or destruction of parts. Failure of one or more

parts can produce abrasive contaminants which may circulate

in the engine oil causing damage to other engine components.

6.

To check for contact between rocker arm and top spring

retainer, perform the following steps:

A.

Paint outside edge of top collar with machinist's blue

and install heads on engine. Modeling clay may also

be used.

B.

Install rocker boxes and pushrods and rotate engine

four revolutions in normal direction of travel.

C.

Remove rocker boxes and examine collar edges for

evidence of any contact with rocker arm.

D.

If contact occurs, remove minimum material necessary

from rocker arm at point of contact.

NOTES:

●

On 1983 and '84 shovelhead engines, rocker cover casting to

top retainer clearance is reduced. When installing S&S

Spring Kit 90-2053 on these engines, be sure to check this

clearance and remove material from rocker cover to assure

.060 minimum clearance.

●

S&S Spring Kit 90-2053 was designed primarily for Harley-

Davidson

®

shovelhead engine. If kit is installed in Harley-

Davidson

®

panhead, valve cover modification will be needed

to provide sufficient clearance between top retainer and

rocker cover. We recommend 1/8" minimum clearance. In

most cases this can be accomplished by peening cover in area

of contact with ballpeen hammer.

2

Before taking measurement, tap

valve stems to set keepers.

Grind material from

top of guide to obtain

measurement B.

A

1.490"

1.520"

B

.600"

.620"

Remove material or shim between bottom of retainer

shoulders and guides or retainer flats and head to obtain

measurement A.

Figure 1

CAUTION