Caution – S&S Cycle Pushrod Kits and Travel Limiters (all) User Manual

Page 7

10. Repeat above procedures for rear cylinder.

11. Replace sparkplugs and pushrod tube clips. Start

motorcycle and check for leaks.

E.

S&S

®

hydraulic lifter limited travel kit (HL

2

T)

All reference to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that any

of S&S

®

Cycle’s products are original equipment parts or that they

are equivalent to the corresponding Harley-Davidson

®

part

number shown.

NOTES:

●

The S&S HL

2

T kit is designed to limit the travel of the

hydraulic lifter making it impossible for the lifter to

collapse. Stronger valve springs are often used to avoid

valve float at high rpm. The HL

2

T kit prevents high valve

spring pressure from collapsing lifters. With the HL

2

T kit

installed, stock hydraulic lifters work like solid lifters at high

rpm, while retaining normal hydraulic function for minimal

noise and maintenance under normal conditions. Another

advantage of the HL

2

T kit is that if a valve is held open

when the engine is not running, valve spring pressure will

not cause lifters to bleed down and collapse. Collapsed

lifters can cause hard starting and excessive valve train noise

when engine is restarted. Adjustable pushrods must be used

with the HL

2

T kit.

●

S&S Kit 33-5338 for 1984 & 1985 big twin, have smaller

diameter hydraulic plunger bodies which measure about

.612". S&S Kit 33-5339 for 1986 to present big twins, have

larger diameter hydraulic plunger bodies which measure

about .655". An early S&S kit must not be used in a late set

of tappets. Installation procedure is the same for either kit.

●

The earlier Harley-Davidson

®

Twin Cam 88

®

lifters, Harley-

Davidson

®

part numbers 18538-99 & 99A, require the S&S

HL

2

T kit number 33-5339. The later Twin Cam 88

®

lifters,

Harley-Davidson

®

part number 18538-99B, require the S&S

HL

2

T kit number 33-5338. Both kits are included with the

Sidewinder

®

engine kits, and either kit is installed and

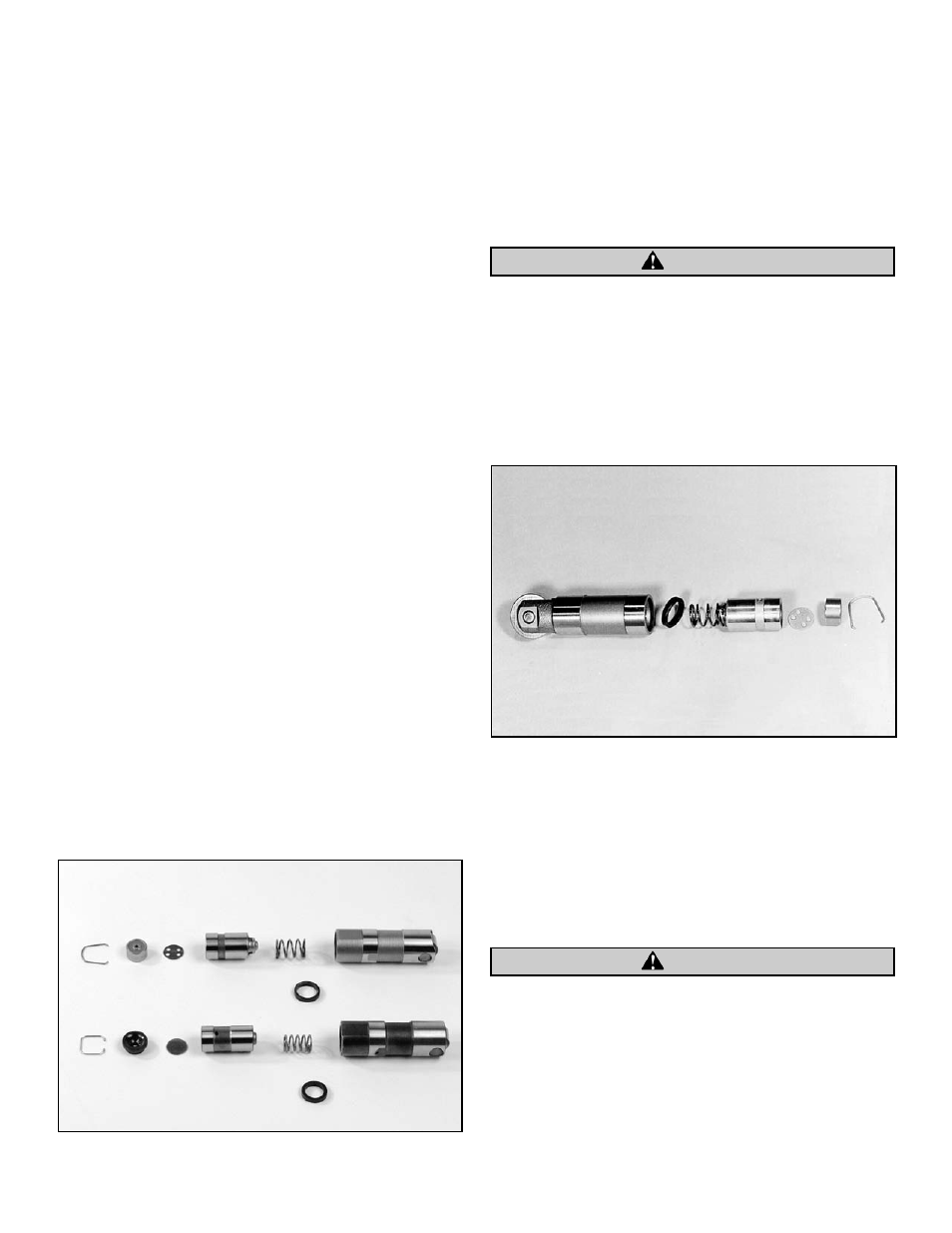

adjusted the same way – remove the retaining clip from the

top of the lifter, and remove the piston assembly and spring

from lifter body. Place the appropriate HL

2

T travel limiter into

the bore of the lifter and replace removed components in the

order that they were removed. See Picture 1.

INSTALLATION

1.

Remove tappet assemblies from engine being sure that

each one is kept with its original tappet block.

NOTE: This procedure is the preferred method of installation.

However, kit can be installed without removing lifters from engine.

2.

Remove hydraulic piston retaining wire clip from one

assembly at a time.

Be careful not to bend wire clip during disassembly.

3.

Completely disassemble tappet removing all parts.

4.

Thoroughly clean all parts including tappet body.

Remove any oil which might prevent hydraulic unit from

fully collapsing during adjustment.

5.

Insert one spacer from S&S HL

2

T kit in tappet body.

6.

Reassemble tappet in reverse order making sure original

parts are returned to their original positions. See Picture 2.

7.

Replace wire retaining clip in tappet body.

8.

Put tappet back in original tappet block.

9.

Repeat Steps 2 through 8 for three remaining tappets.

10. Reassemble engine with modified tappets.

11. Adjust pushrods.

NOTE: In all cases engine must be cold and lifter must be at

lowest point of travel for pushrod adjustment

To prevent accidents, remove ground cable from battery.

7

CAUTION

Picture 1

Picture 2

CAUTION