Caution – S&S Cycle Transmission Case, 4-to-5 Speed User Manual

Page 4

5.

Clearance access door to match clearance cut in 56-1051

transmission case below starter motor area. See Picture 3.

B.

Parts Preparation

1.

Countershaft

Remove approximately 0.280 in. from non-threaded

end of countershaft and remove burrs. Correct length of

modified countershaft is 7.830 in.

NOTE: Countershaft is hardened, so grinding shaft to correct size

may be preferable to cutting.

2.

Shifter Shaft

a.

Remove approximately 0.200 in. from either end of

shifter shaft and remove burrs. Correct length of

modified shifter shaft is 7.265 in.

3.

Inner Primary Housing

a.

Remove old mainshaft bearing and seal.

b.

Clean bearing race in primary housing with lacquer

thinner or Loctite primer.

c.

Apply thin film of Loctite 609 (supplied) to outside of

S&S

®

Mainshaft Adapter Spacer 56-1068. See Parts 16

and 20-21 in Figure 1 on pg 6. Press spacer into inner

primary cover until spacer contacts step in bore.

Area of primary cover below step must be firmly supported to

prevent damage when adapter spacer, bearing, and seal are

installed.

d.

Observing caution mentioned above, press supplied

mainshaft bearing 56-5100 into Mainshaft Adapter

Spacer until bearing contacts step.

e.

Press seal 56-5101 into inner primary housing until

it contacts bearing.

NOTE: Install seal with spring facing away from transmission,

toward outside of motorcycle.

Failure to install seal correctly may allow sprocket nut to

contact and damage seal, resulting in primary fluid leak.

C.

Assembly

After modification of countershaft and shift fork shaft,

installation of shafts, gear assembly, and other parts in case

is identical to procedure required for Harley-Davidson

®

five-speed transmission. Differences in installation from

standard four-speed procedure apply to transmission

sprocket, starter/battery box brackets, shift linkage, and FX

model footpeg mount.

NOTE: 1982-1984 big twin sprocket for five-speed transmission is

required. Harley-Davidson

®

has the correct sprocket available in

23-tooth version only. Most aftermarket suppliers have 24-tooth

sprocket available as well.

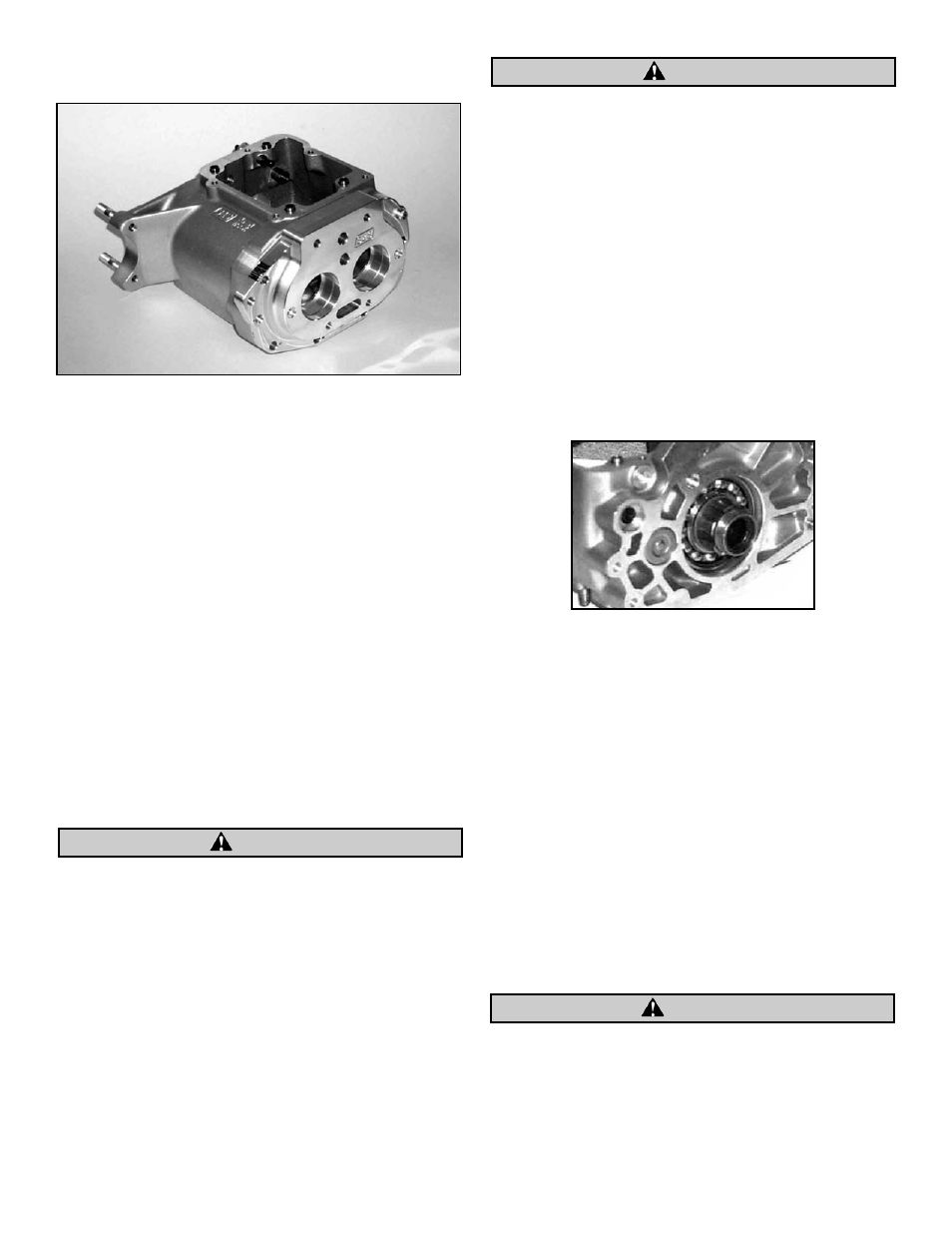

1. Install Quad Seal 50-8045 on main drive gear. See

Picture 4.

2.

Lubricate chamfer on I.D. of Sprocket Spacer 56-3004

with clean transmission lubricant and install spacer on

main drive gear. Chamfer on I.D. of spacer must face

Quad Seal.

3.

Clean threads of main drive gear with lacquer thinner or

Loctite

®

primer and apply thin film of Loctite #609.

4.

Install sprocket nut 56-3003. Torque nut to 110-120 ft-lbs.

NOTES

G Supplied sprocket nut is thin, early style. This type nut

must be used to prevent interference with seal in inner

primary housing.

G Before completing assembly, check for adequate clearance

between drive chain and transmission case. Clearance must

also be checked between chain and inner primary housing.

With properly adjusted chain, clearance must be at least

.040" on each side. S&S has used heavy-duty o-ring chains in

4-5 speed applications, but existing clearance is minimal.

Failure to properly clearance parts may result in damage not

covered under warranty.

4

Picture 3

Picture 4

CAUTION

CAUTION

CAUTION