Caution – S&S Cycle Speedometer Calibrator (Part 55-1007) User Manual

Page 2

The S&S

®

Speedometer Calibrator allows owners of Harley-

Davidson

®

and Buell

®

motorcycles equipped with stock electronic

speedometers (those with LCD mileage displays) to correct

inaccurate speedometer and odometer readings. Typically, these

are caused by the installation of different transmission or wheel

sprockets, early stock or aftermarket transmission gears, or rear

tires with a diameter other than stock.

The S&S Speedometer Calibrator allows the rider to correct

Harley-Davidson

®

electronic speedometers easily and without

special tools or expensive test equipment. Adjustments can be

made between -29% and +69% in 1% increments.

The calibrator’s small size permits convenient mounting, and

sensitive components are sealed for protection against weather

and vibration.

To prevent possible damage to motorcycle electrical system,

disconnect battery ground lead (“-”) from motorcycle frame

prior to installing calibrator.

Installation

1.

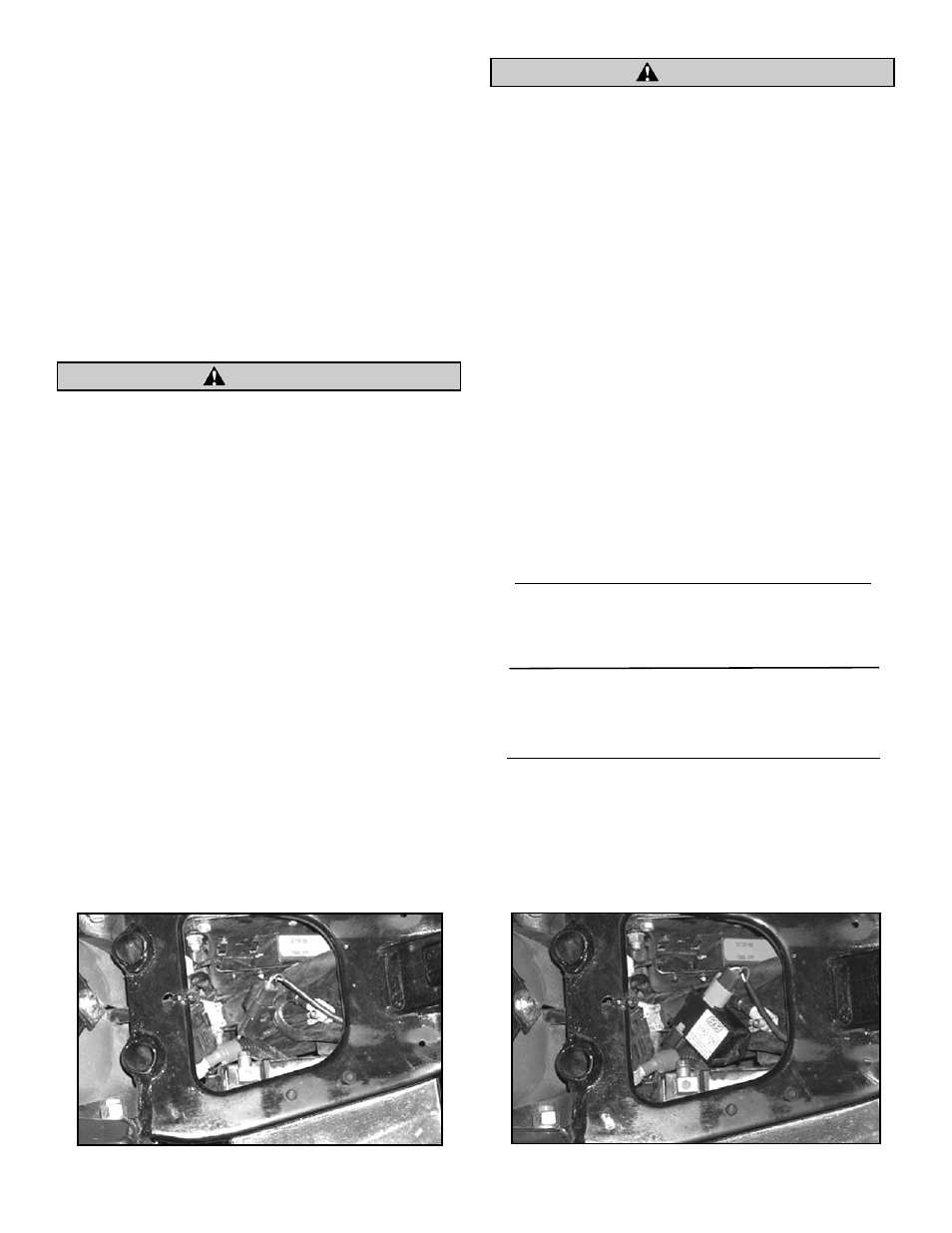

Place pressure on release clips and unplug wiring connector

between speedometer and transmission sensor. Connector is

usually located under seat. See Picture 1.

2.

Attach male and female ends of connector to respective

ends of S&S Speedometer Calibrator and secure calibrator

and wires to motorcycle. See Picture 2. Route wires to avoid

stretching, pinching, and chafing against frame. Reconnect

battery ground lead to frame.

NOTE - Calibrator features screw-eyes, but can be mounted with

wire-ties if desired.

Improperly routed wires may wear and short against frame,

causing extensive damage to motorcycle electrical system and

possible fire hazard.

3.

Initial setting of adjustment screws should be “0” position.

See Picture 3.

NOTE - Slot in each screw has small notch in one end. Notched

end must point toward selected number. Screws can be rotated

full 360 without damage.

Determine Calibration Percentage

1.

Determine amount of speedometer error. Most common

methods are to compare speedometer reading to

speedometer known to be accurate, or compare odometer

reading (mileage) to measured distance. Highway markers

are usually accurate, but readings from several different

markers should be taken and compared for confirmation.

Radar can also be used to determine actual speed. In case of

gear change, number of teeth on original and replacement

sprockets can also be used to determine percentage of

speedometer error. Note that formulae for transmission and

wheel sprockets are different.

2.

Calculate percentage of speedometer error using one of

following formulas:

Actual Speed (or mileage) - Indicated Speed (or mileage)

Indicated Speed (or mileage)

OR:

# of teeth on new trans. sprocket - # of teeth on original sprocket

# of teeth on original trans. sprocket

OR:

# of teeth on original wheel sprocket - # of teeth on new sprocket

# of teeth on original wheel sprocket

2

CAUTION

CAUTION

Picture 1

Picture 2