Flow system – RKI Instruments 35-3000RKA-LEL User Manual

Page 3

Sample Draw Combustible Gas Detector • 3

Flow System

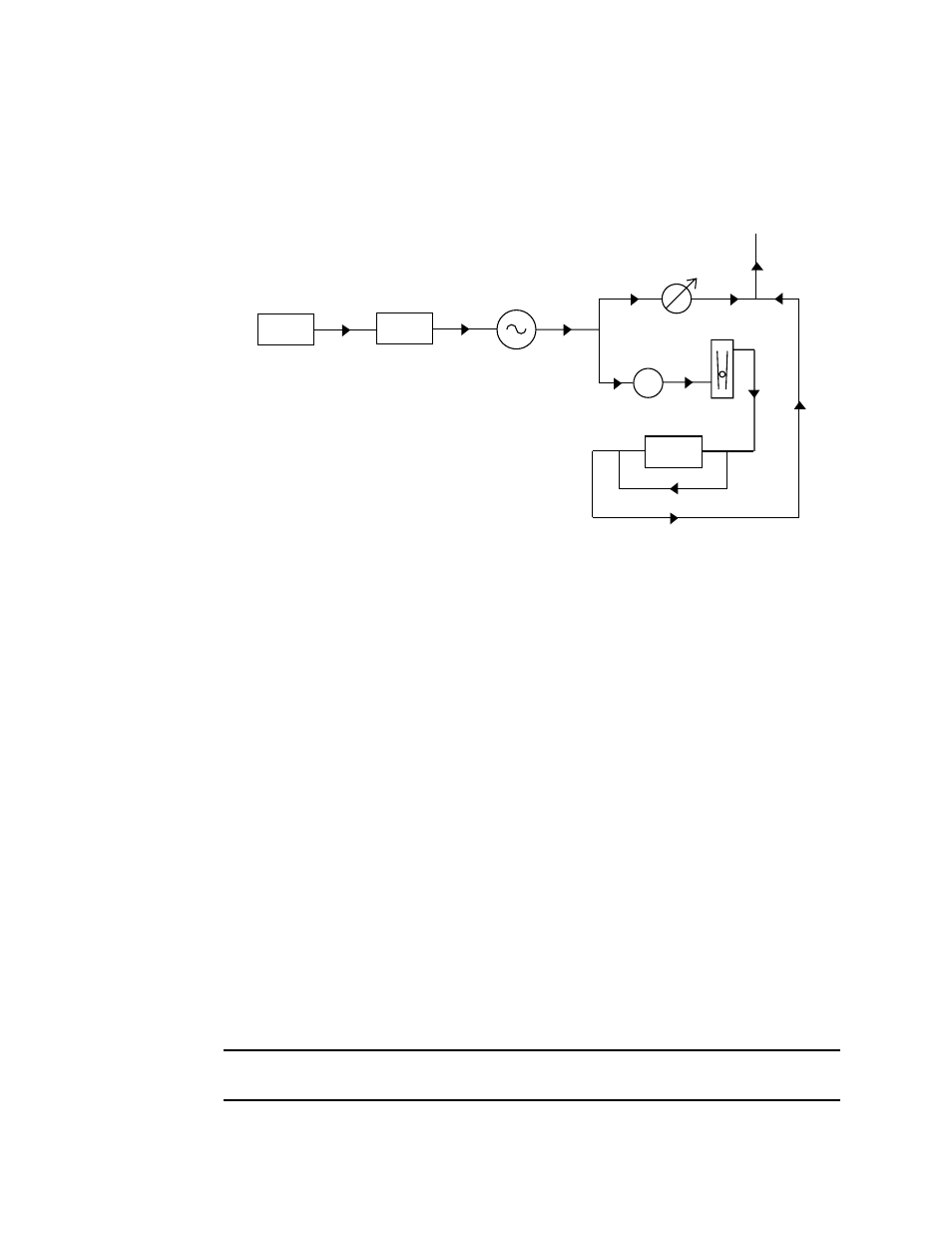

The sample draw detector’s flow system consists of the INLET fitting, filter, pump,

flowmeter, bypass valve, status lights, pressure switch, and EXHAUST fitting (see

Figure 1). Figure 2 illustrates how the gas sample moves through the flow system.

Figure 2: Sample draw Combustible Gas Detector Flow Diagram

INLET fitting

The INLET fitting on the right side of the housing allows the gas sample to enter the

sample draw detector. The INLET fitting accepts 1/4 in. rigid tubing. See the Installation

section on page 7 to connect tubing to the INLET fitting.

Filter

The dust filter is below the main circuit board. The filter prevents particulates in the

incoming gas sample from damaging the flow and detection systems. Replace the filter

when it appears dirty, discolored, or clogged.

Pump

The pump is behind the main circuit board near the top of the sample draw detector.

The pump pulls the gas sample into the sample draw detector. The pump operates on

24 VAC, which is generated from the 24 VDC supplied to the sample draw detector.

Flowmeter

The flowmeter is attached to the main circuit board near the top left corner (see Figure 1.)

You can see it through the window in the door. A ball in the flowmeter column indicates

the flow rate of the sample draw detector. The flowmeter measures the flow in the range

0.2 to 2.0 SCFH (Standard Cubic Feet per Hour). The optimum flow rate is 1.5 SCFH.

Bypass valve

The bypass valve is to the left of the flowmeter. The bypass valve adjusts the flow rate to

the sensor. Use a flat-blade screwdriver to adjust the bypass valve.

NOTE:

The bypass valve allows fine adjustments of the flow rate. For a wider range of

adjustment, use the flow adjust potentiometer (see Figure 1.)

Inlet

Filter

Pump

Sensor

Flowmeter

Pressure Switch

Exhaust

To

Valve

Bypass