RKI Instruments SDM-E2 User Manual

Page 30

25 • Connecting Calibration Gas

Use Table 4 below as a guide in determining which calibration gas cylinder is

appropriate for your system. See “Spare Parts List” on page 80 for a list of available

cylinder part numbers.

To connect calibration gas to the SDM-E2, do the following:

1.

If the area around the docking station is not considered a fresh air area (an

area free of combustible and toxic gases and of normal oxygen content,

20.9%) install a tube not longer than 10 feet on the filter attached to the AIR

fitting on the back of the docking station and route it to a fresh air area or

connect a cylinder of zero air with a demand flow regulator to the AIR fitting.

2.

Install the demand flow regulator on the calibration gas cylinder(s).

3.

Connect the demand flow regulator to the GAS 1 or GAS 2 inlet fitting using

the 3 foot length of 3/16 inch ID sample tubing provided with the docking

station.

For a 3- or 4-gas mix, connect the regulator to the GAS 1 inlet.

For a special calibration cylinder (PID, TC, ESM-01, etc.), connect the

regulator to the GAS 2 inlet.

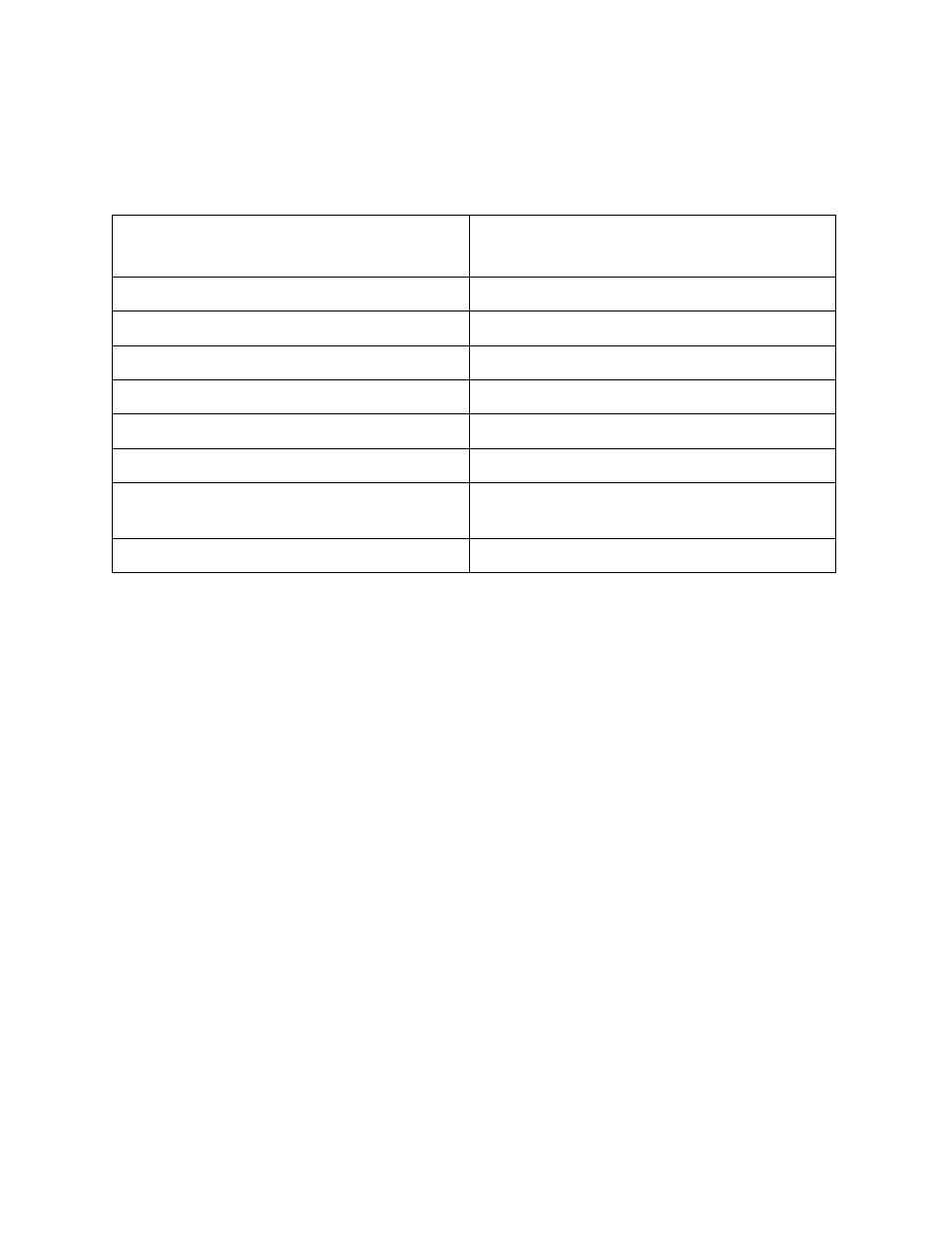

Table 4: Recommended Gas Cylinders for Typical Instrument Types

Typical Instrument Types

Recommended Calibration Gas

Cylinder

3-gas (LEL/Oxy/CO)

3-gas mix with LEL/Oxy/CO

Standard 4-gas (LEL/Oxy/H2S/CO)

4-gas mix with LEL/Oxy/H2S/CO

Standard 4-gas + low range PID

4-gas mix and IBL

Standard 4-gas + high range PID

5-gas mix with LEL/Oxy/CO/H2S/IBL

Standard 4-gas + NH3

4-gas mix and NH3

Standard 4-gas + low range PID + NH3

4-gas mix and IBL and NH3

Standard 4-gas + high range PID + NH3

5-gas mix with LEL/Oxy/CO/H2S/IBL and

NH3

Standard 4-gas + SO2

5-gas mix with LEL/Oxy/CO/H2S/SO2