Concrete, Purusline living wetroom solution, Tile grout waterproof membrane tile adhesive – Purus Living 800 - Tile Insert Grate User Manual

Page 14

14

PURUSLINE LIVING WETROOM SOLUTION

Concrete

NO

TE: Once

installed

and the

G

rout

is

fully

dr

y,

check for

leaks

befo

re

using.

NOTE: Prior

to

tiling

an

unde

rfloor

heat-

ing mat

can

be

laid,

ensuring

that

the

maximum height

of

13

mm

is

not

exceeded.

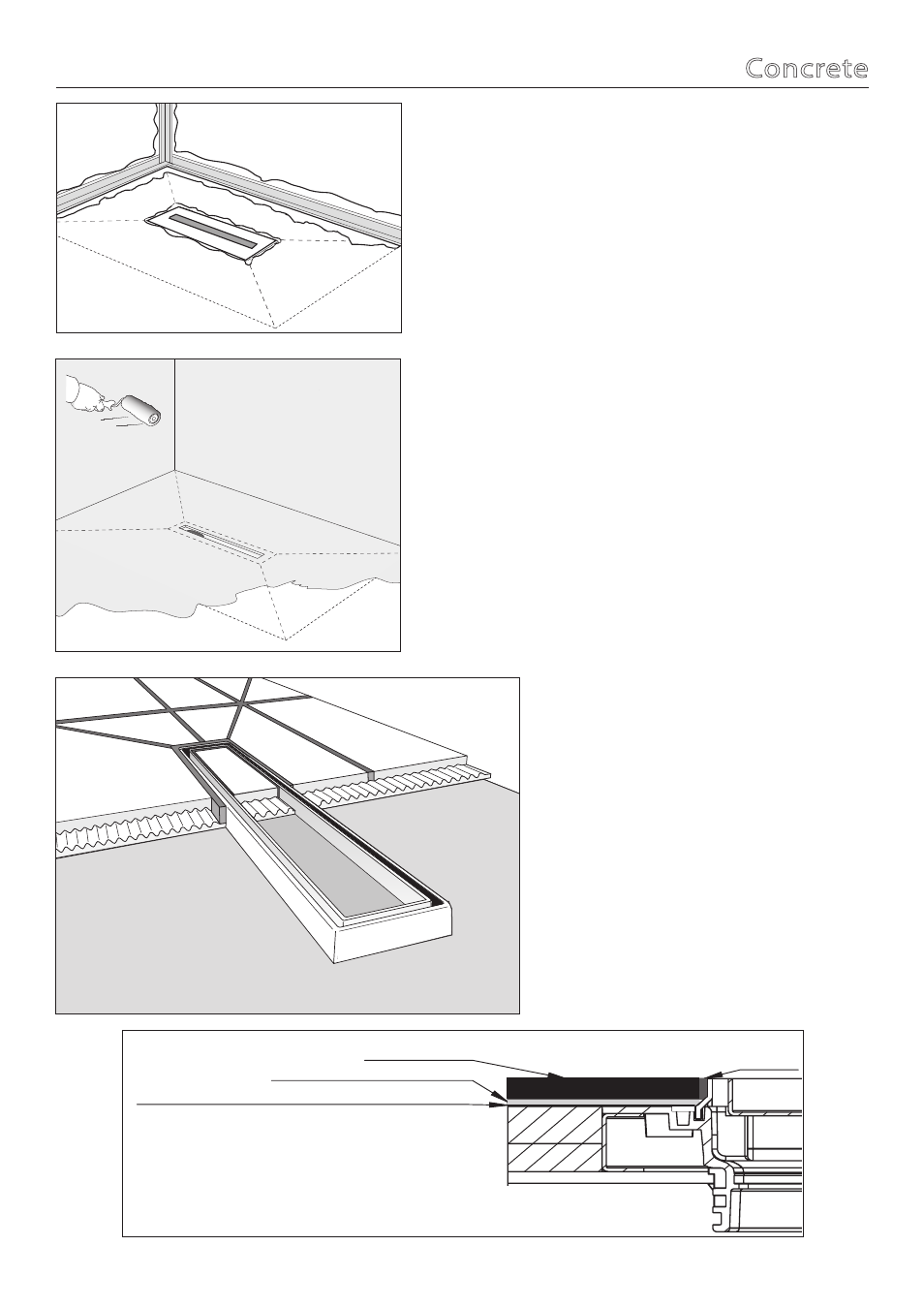

Place the gasket around the gully to check if it fits. Take the Pura Elastomeric Tapes

and dry cut to all wall and floor joints.

Once the MS Polymer has tacked over, using a brush or roller apply the Puragum

to all wall and floor joints one at a time. Apply the Pura Elastomeric Tapes while the

Puragum is still wet, firmly smoothing down the tape as you go so there are no air

pockets or ridges left and the tapes are fully adhered. Ensure the Puragum goes

up the sides of the tile insert grate ensuring you have enough Puragum to overlap

the gasket (when applying the Puragum ensure the weep holes are kept intact).

The gasket membrane is then mounted to the upper part of the channel by using

the Puragum. Firmly smooth down the gasket and tapes so there are no air pockets

or ridges left and the gasket is fully adhered. Make sure the gasket is centred. Now

allow to dry for 3 hours.

Now cover the whole floor, tape, gasket and walls with one coat of Puragum and

allow to dry for another 3 hours, then apply a second coat. Ensure the Puragum

goes up the sides of the tile insert grate ensuring you overlap the gasket with the

two coats of Puragum (when applying the Puragum ensure the weep holes are

kept intact). Leave to dry for a minimum of 24 hours before tiling depending on

site conditions.

Once the second coat of Puragum has fully cured, check the tapes and

gasket are fully secure and sealed before tiling.

Ensure the tanking kit is installed as per the instructions. Ensure you follow

the tanking kit instructions and that all porous surfaces such as concrete and

plasterboard are primed with Puragum Primer. Also ensure that the tapes and

membranes are fully secure before tiling.

Ensure you keep to the minimum drying times. Drying times could be

longer depending on site conditions.

Tile to the desired pattern, followed by the insert cover using flexible EN12004

C2 classified tile adhesive applied using a notched trowel in accordance with the

code of practice BS5385:2009.

Tile

Grout

Waterproof membrane

Tile adhesive

02830

Fix the tiles with adhesive that fastens to stainless steel.

Use a small straight edge up against the gully gap so as to

prevent the tile adhesive falling into the gully body.

Finally grout the gaps with flexible, water proof, anti-mould

grout, ensuring that no grout falls into the gully body. Leave

to dry and settle for 48 hours.

If tile adhesive or grout falls into the gully immediately clean

it up.

The grate when installed must be horizontal and flat. It also

must be level with the ceramic tile surface and not at an angle

or on a slope.

NOTE: Once installed and the grout is fully dry, check for leaks

before using.

Fix Tiles to BS5385 Standard.

Falls in scr

eed

Falls in screed